A Locking and Adjusting Mechanism for Plate Cylinder of Flexo Printing Machine

A technology of adjusting mechanism and locking mechanism, which is applied in the direction of printing presses, rotary printing machines, rotary printing machines, etc., can solve the problems of easy errors in the production process, inconvenient use, low work efficiency, etc., and achieve the effect of fast positioning and locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

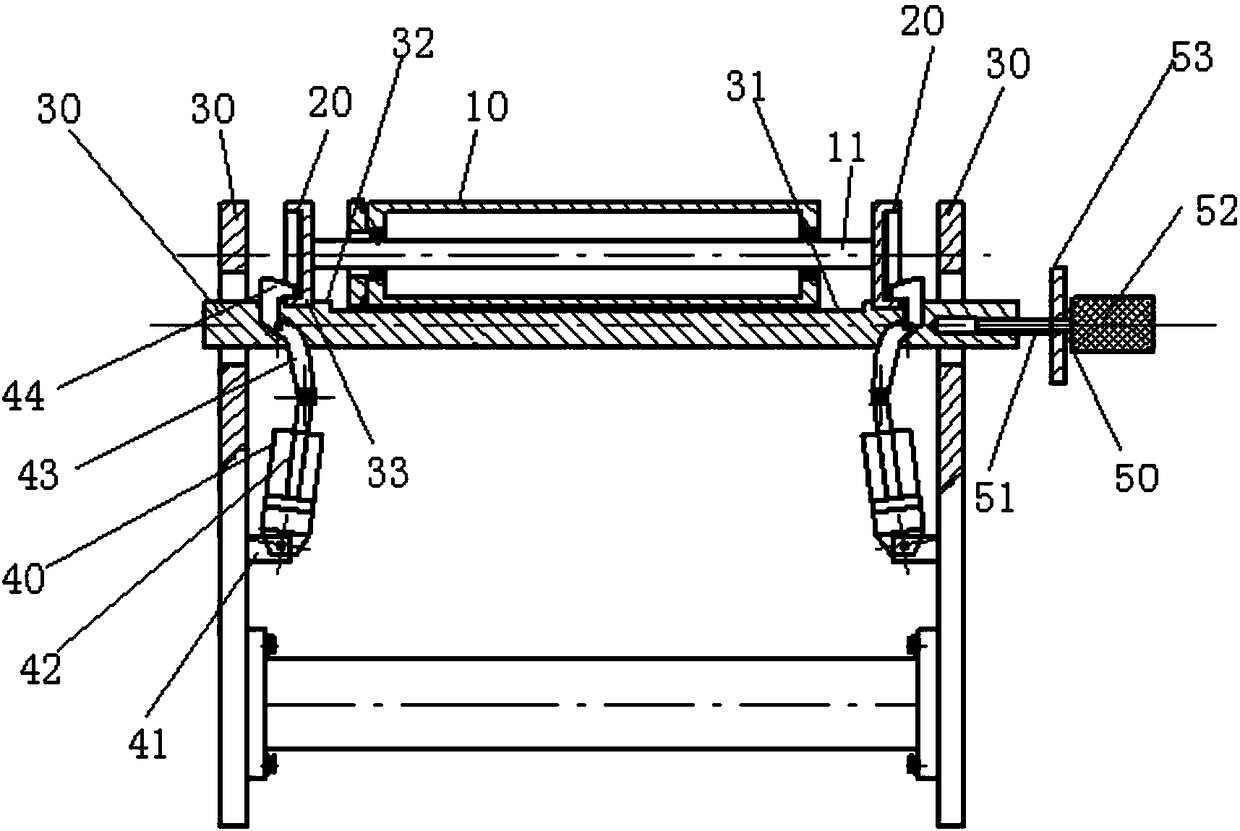

[0024] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

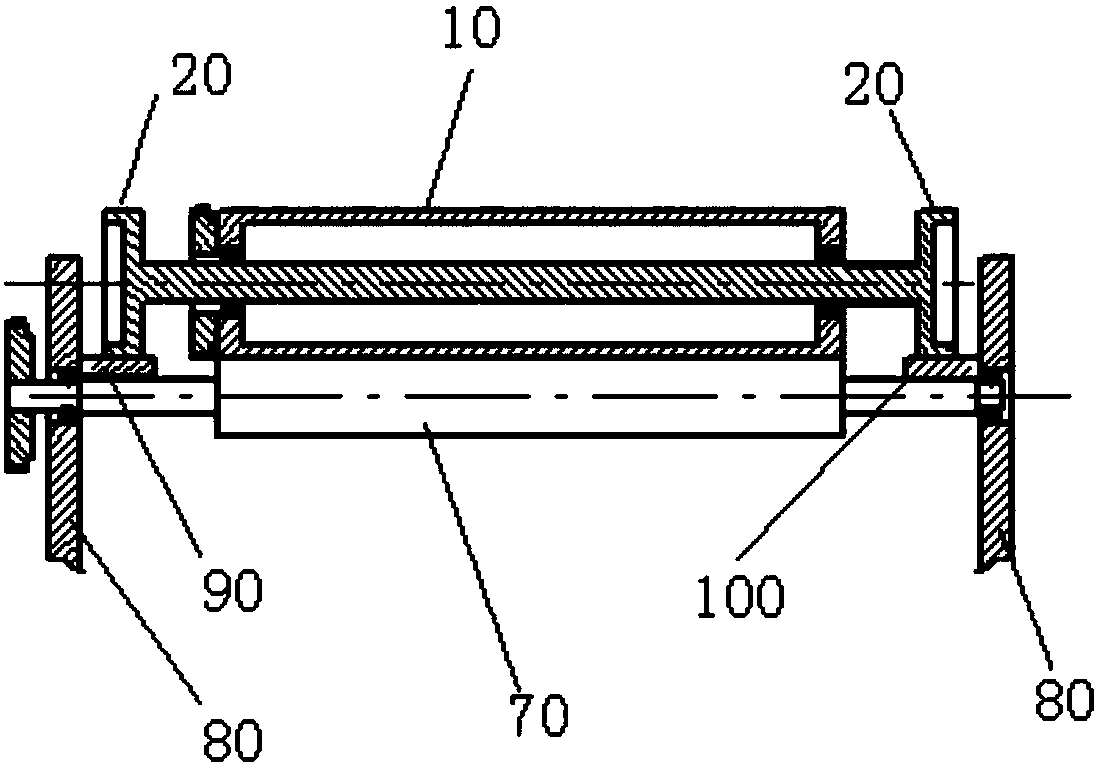

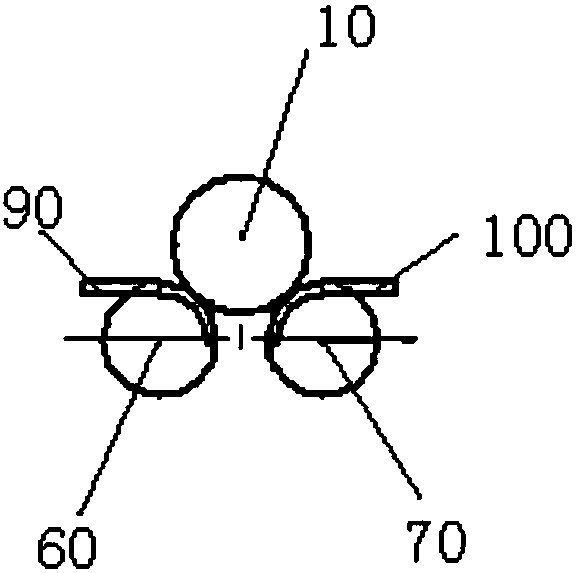

[0025] See Figure 3 to Figure 5 As shown, the present invention discloses a flexo printing machine plate roller locking and adjusting mechanism. The flexo printing machine plate roller locking and adjusting mechanism includes a pair of fixed discs 20 arranged at both ends of the flexo printing machine plate roller 10. The beam 30, a pair of locking mechanisms 40, and a lateral adjustment mechanism 50 for adjusting the flexographic printing press plate roller left and right.

[0026] The outer diameter of the fixed disk 20 is the same as the outer diameter of the flexographic printing machine plate roller 10, and the two fixed disks 20 are fixedly connected to the two ends of the central shaft 11 of the flexographic printing machine plate roller 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com