Aviation building tray stopper driving device

A driving device and stopper technology, applied in the direction of conveyor control devices, transportation and packaging, conveyor objects, etc., can solve the problems of large size, slow response speed, time-consuming and other problems of mechanical driving devices, and achieve beautiful appearance , weight reduction, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

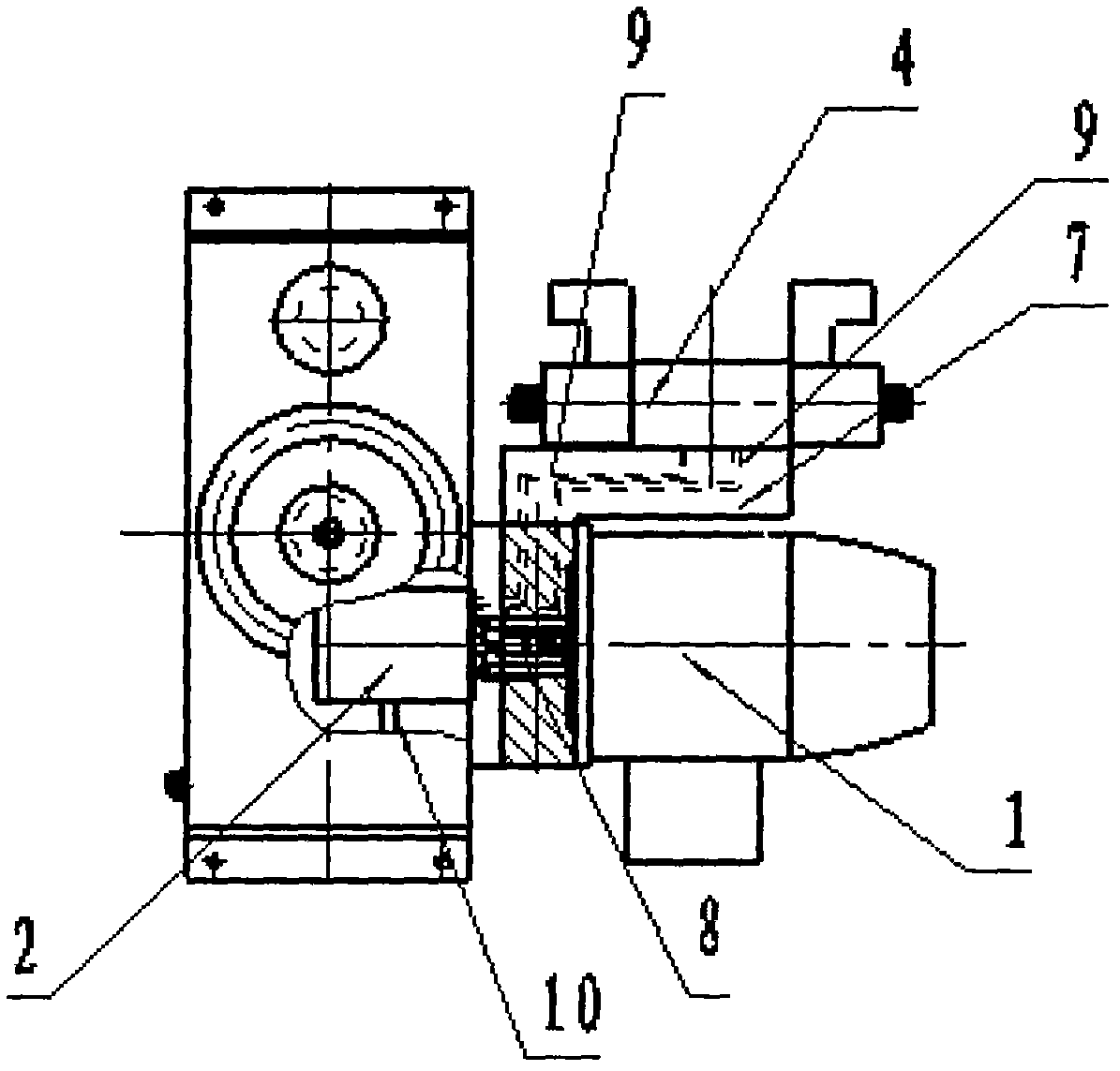

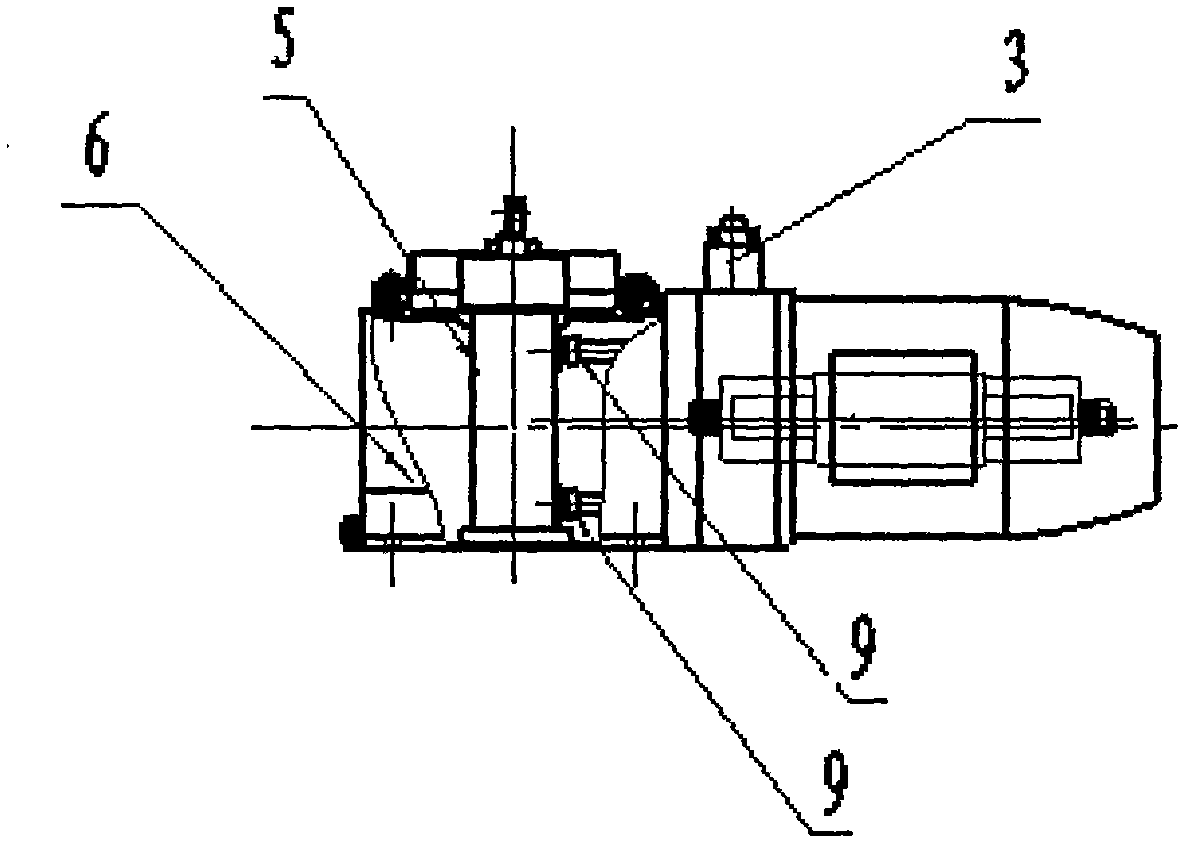

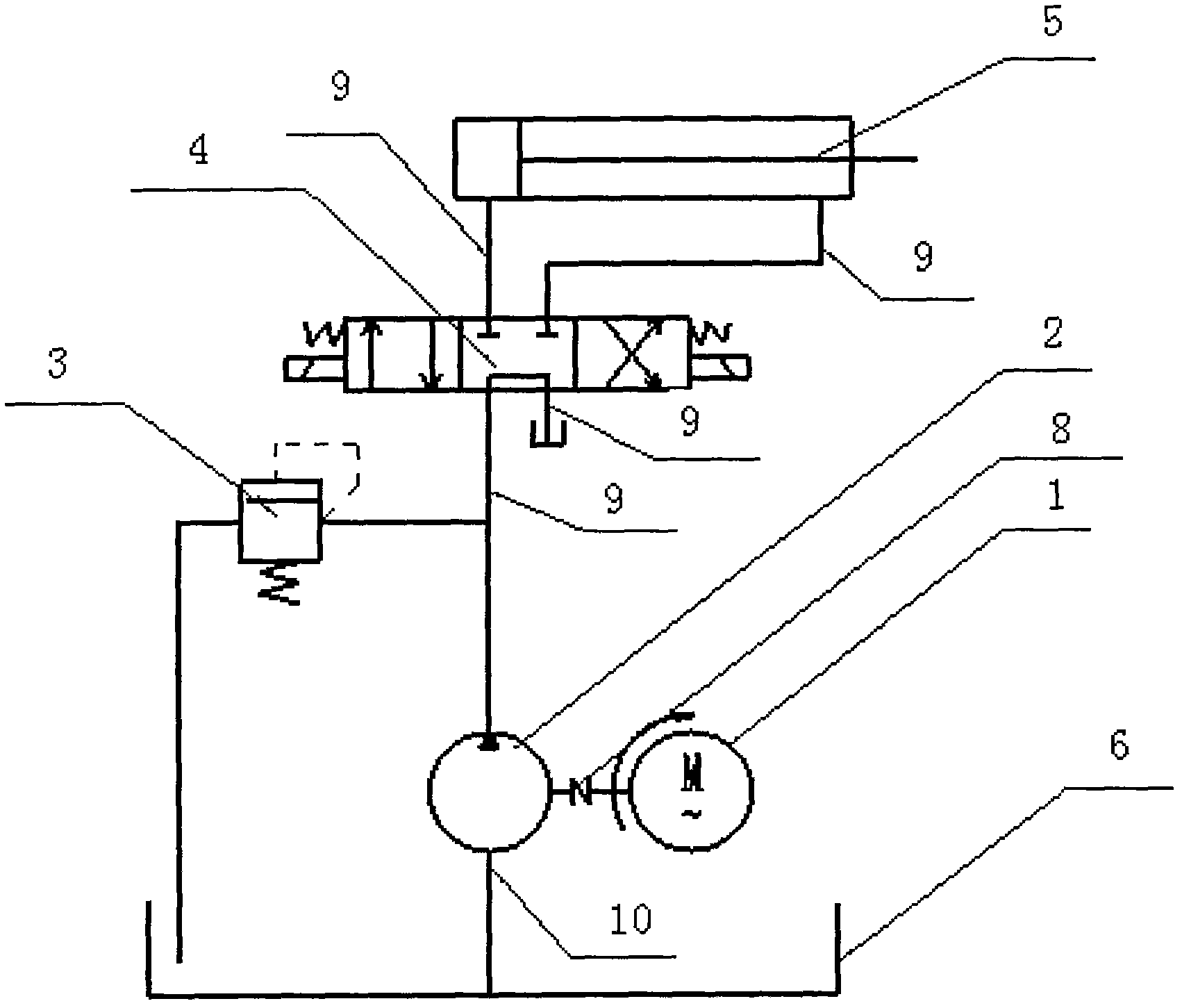

[0013] see figure 1 , figure 2 and image 3 , a driving device for a pallet stopper in an aviation building, comprising a motor 1, an oil pump 2, an overflow valve 3, an electromagnetic reversing valve 4, an oil cylinder 5, an oil tank 6, a valve seat 7, the shaft of the motor 1 and the The shaft of the oil pump 2 is connected with the shaft coupling 8; the oil pump 2 is connected with the oil tank 6 through the oil pipe 10, and the oil pump 2 is connected with the pressure of the overflow valve 3 and the electromagnetic reversing valve 4 through the oil pipe 9 respectively. The electromagnetic reversing valve 4 is an "M-type" reversing valve with a median function, and the electromagnetic reversing valve 4 is provided with two pressure oil outlets, and the two pressure oil outlets are The oil pipe 9 is respectively connected with the rod chamber and the rodless chamber of the oil cylinder 5. The electromagnetic reversing valve 4 is provided with an oil return port, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com