A hydraulic support for active crushing of caving coal

A hydraulic support and top-coal caving technology, which is applied in mine roof support, mining equipment, earthwork drilling and mining, etc., can solve the problems of poor top-coal crushing effect affecting top-coal recovery rate, etc., achieve reasonable and reliable structural design, improve efficiency, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

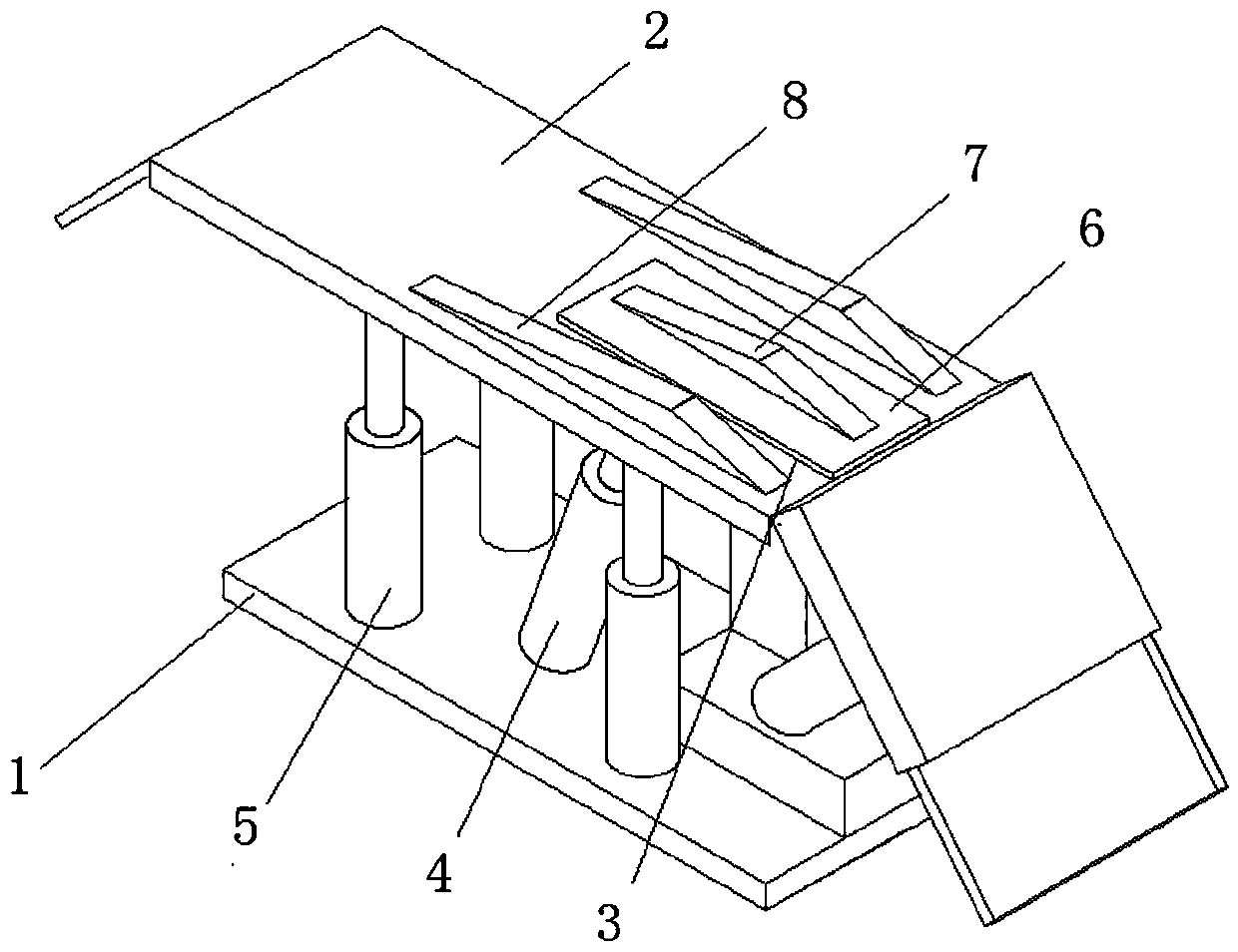

[0010] A hydraulic support for active crushing of top coal caving, comprising a base 1 and a top beam 2, an inner top beam 3 is inlaid in the middle of the top beam 2, and an inner telescopic column 4 hinged with the two is arranged between the inner top beam 3 and the base 1, An outer telescopic column 5 hingedly connected to the two is provided between the top beam 2 on the outer side of the inner top beam 3 and the base 1, the upper end of the inner top beam 3 is provided with an impact vibration table 6, and the upper end of the impact vibration table 6 is provided with an inner coal breaking plate 7. , the upper end surfaces of the top beam 2 on the left and right sides of the shock vibration table 6 are provided with outer coal breaking plates 8 .

[0011] In the specific implementation process, the roof beam 2 is 1500mm wide, 6000mm long, and 200mm thick, and the gap in the middle of the roof beam 2 is 500mm wide, 2000mm long, and 100mm deep, which are used for inlaying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com