Artificial turf supporting pad and preparation method thereof

A technology for artificial turf and support pads, applied in construction, roads, pavements, etc., can solve problems such as increased costs, unfavorable environment, and odor defects, and achieve the effects of reducing production costs, improving production efficiency, and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

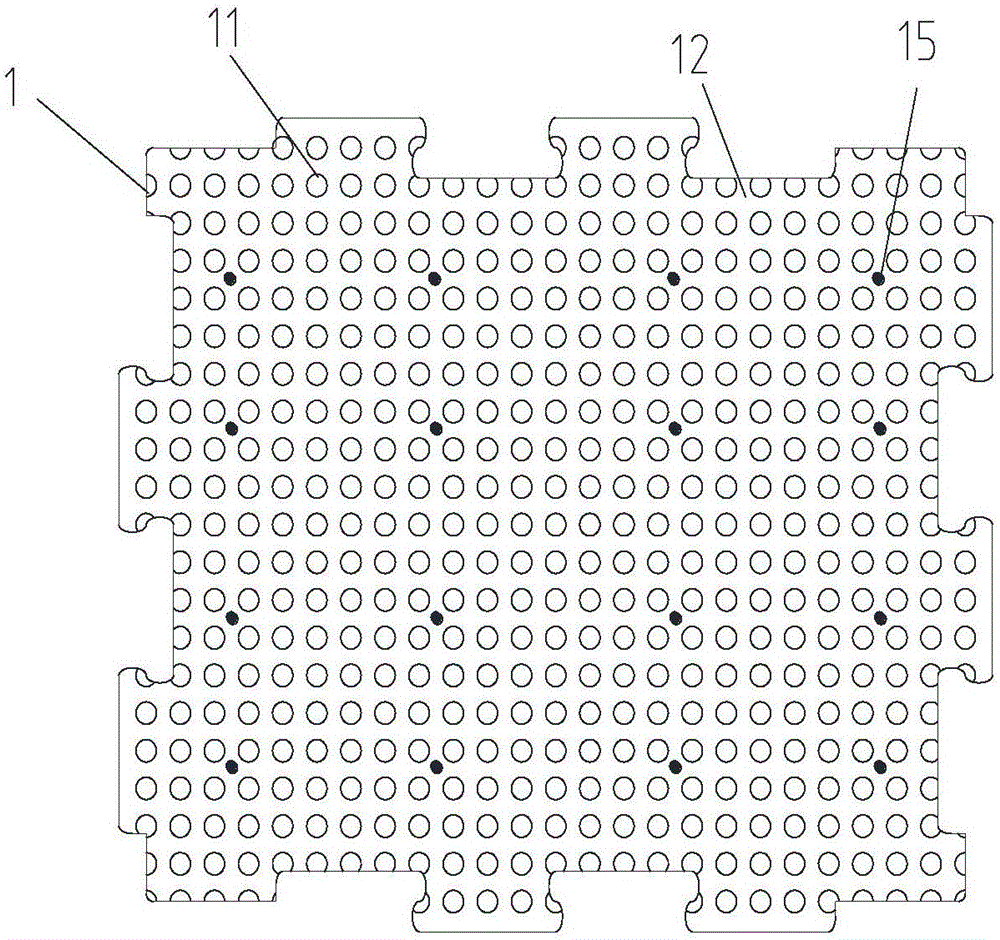

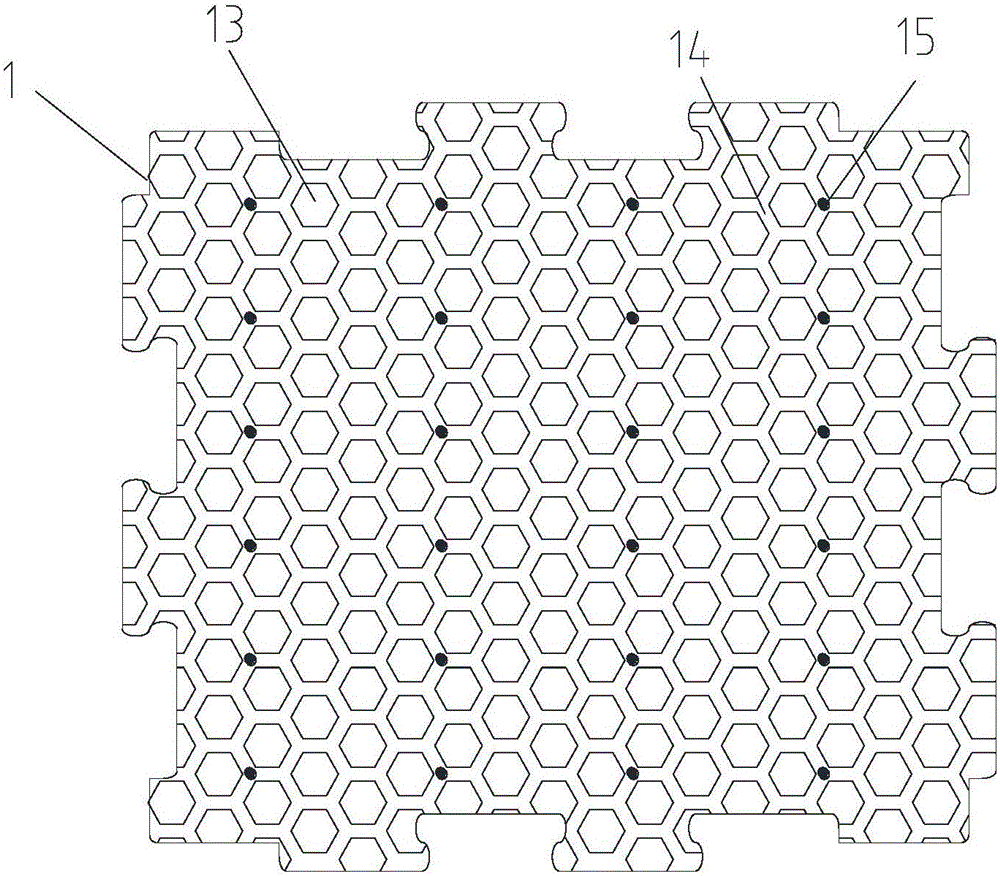

[0049] refer to figure 1 and combine figure 2 , an artificial turf support pad, comprising a main backing plate 1; the thickness of the main backing plate 1 is 20mm;

[0050] The upper surface of the main backing plate 1 is provided with several circular upper protrusions 11 and upper grooves 12; the circular upper protrusions 11 protrude upward and are evenly spaced on the upper surface of the main backing plate 1; The upper groove 12 is formed by connecting the depressions between two adjacent circular upper protrusions 11;

[0051] The lower surface of the main backing plate 1 is provided with several hexagonal lower protrusions 13 and lower grooves 14; the hexagonal lower protrusions 13 protrude downward and are evenly spaced on the lower surface of the main backing plate 1; The lower groove 14 is formed by connecting the depressions between two adjacent hexagonal lower protrusions 13;

[0052] The thickness of the circular upper convex part 11 is 0.2 mm, and the thick...

Embodiment 2-3

[0056] According to the thicknesses of the main backing plate 1, the upper convex portion 11 and the lower convex portion 13 specified in Table 1 below, different artificial turf support pads were obtained respectively, and the rest of the structures and features were the same as in Example 1.

[0057] Table 1 The thickness of the main backing plate, the upper convex part and the lower convex part of the embodiment 1-3

[0058]

Example 1

Example 2

Example 3

Main plate thickness (mm)

20

30

40

Thickness of the upper convex part (mm)

0.2

1

2

Thickness of lower convex part (mm)

2.5

3

4

[0059] Pass the artificial turf support pad of embodiment 1-3 into the water flow, detect the water flow velocity of the upper groove 12 and the lower groove 14, and test its drainage effect, the results are as shown in table 2:

[0060] The water velocity in the upper groove and the lower groove of table 2 embodiment 1-3 ...

Embodiment 4

[0063] A preparation method of an artificial turf support pad, comprising the following steps:

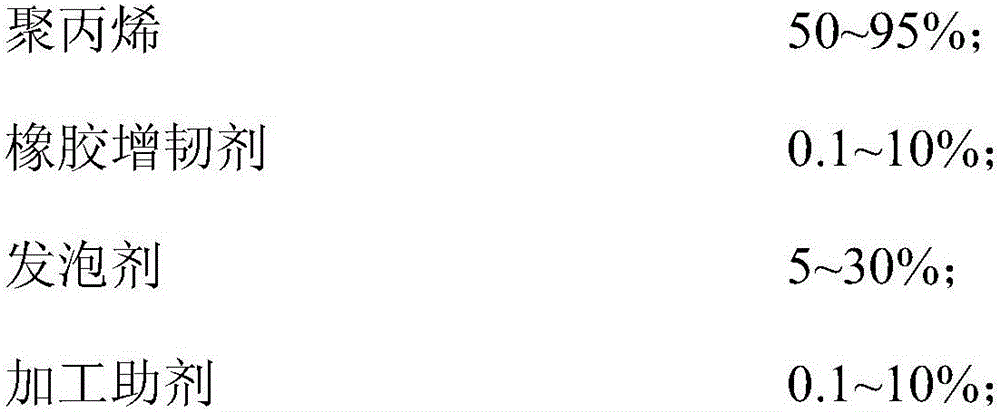

[0064] 1) Prepare the following raw materials by weight percentage:

[0065]

[0066]

[0067] 2) preparing expanded polypropylene particles by using the raw materials described in step 1) by kettle pressure method or extrusion method;

[0068] 3) The foamed polypropylene particles obtained in step 2) are thermocompressed through a mold to obtain an artificial turf support pad.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com