A kind of aniline calfskin finishing composition and finishing process thereof

A calfskin and composition technology, which is applied in the field of aniline calfskin finishing composition and its finishing process, can solve the problems that calfskin is difficult to achieve covering effect, affects the feel and brightness of calfskin, and achieves good covering effect and utilization rate, Good coverage and good feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

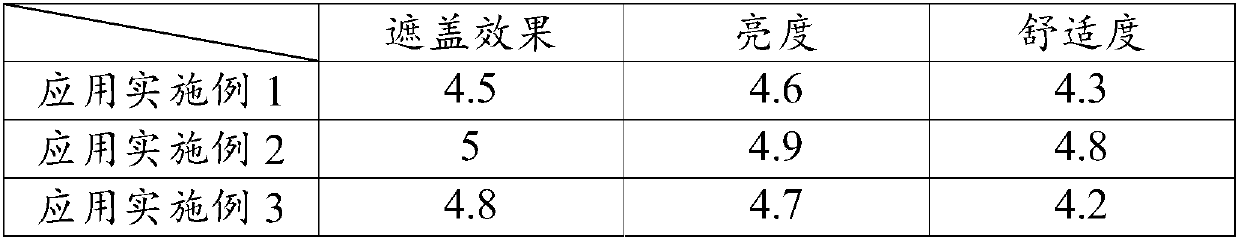

Examples

Embodiment 1

[0071] An aniline calfskin finishing composition, which includes spray oil, cationic paste, face paste and bright liquid; wherein,

[0072] The spray oil consists of the following components in parts by weight: 180 parts of water, 40 parts of penetrant, 40 parts of cationic oil, and 15 parts of dye;

[0073] The cationic slurry is composed of the following components in parts by weight: 350 parts of water, 25 parts of penetrant, 15 parts of cationic oil, 80 parts of cationic casein, 80 parts of cationic polyurethane, 40 parts of cationic wax; 25 parts of cationic brown paste ;

[0074] The batter consists of the following components in parts by weight: 320 parts of water, 15 parts of resin, 40 parts of polyurethane resin, 25 parts of polishing resin, 40 parts of acrylic resin, 40 parts of comprehensive wax, 25 parts of nonionic hand feeling agent, butter 40 parts of pigment, 40 parts of penetrant, 10 parts of dye;

[0075] The bright liquid is composed of the following compo...

Embodiment 2

[0088] An aniline calfskin finishing composition, which includes spray oil, cationic paste, face paste and bright liquid; wherein,

[0089] The liquid spray oil consists of the following components in parts by weight: 200 parts of water, 50 parts of penetrant, 50 parts of cationic oil, and 20 parts of dye;

[0090] The cationic slurry is composed of the following components in parts by weight: 400 parts of water, 30 parts of penetrant, 20 parts of cationic oil, 100 parts of cationic casein, 100 parts of cationic polyurethane, 50 parts of cationic wax; 30 parts of cationic brown paste ;

[0091] The batter consists of the following components in parts by weight: 350 parts of water, 20 parts of resin, 50 parts of polyurethane resin, 30 parts of polishing resin, 50 parts of acrylic resin, 50 parts of comprehensive wax, 30 parts of nonionic hand feeling agent, butter 50 parts of pigment, 50 parts of penetrant, 15 parts of dye;

[0092] The bright liquid consists of the following...

Embodiment 3

[0105] An aniline calfskin finishing composition, which includes spray oil, cationic paste, face paste and bright liquid; wherein,

[0106] The spray oil consists of the following components in parts by weight: 250 parts of water, 60 parts of penetrant, 60 parts of cationic oil, and 25 parts of dye;

[0107] The cationic slurry is composed of the following components in parts by weight: 450 parts of water, 40 parts of penetrant, 25 parts of cationic oil, 120 parts of cationic casein, 120 parts of cationic polyurethane, 60 parts of cationic wax; 35 parts of cationic brown paste ;

[0108] The batter consists of the following components in parts by weight: 380 parts of water, 25 parts of resin, 60 parts of polyurethane resin, 35 parts of polishing resin, 60 parts of acrylic resin, 60 parts of comprehensive wax, 35 parts of nonionic hand feeling agent, butter 60 parts of pigment, 60 parts of penetrating agent, 20 parts of dye;

[0109] The bright liquid is composed of the follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com