Automotive suspension vibration damper energy characteristic testing system and automotive suspension vibration damper energy characteristic metering method

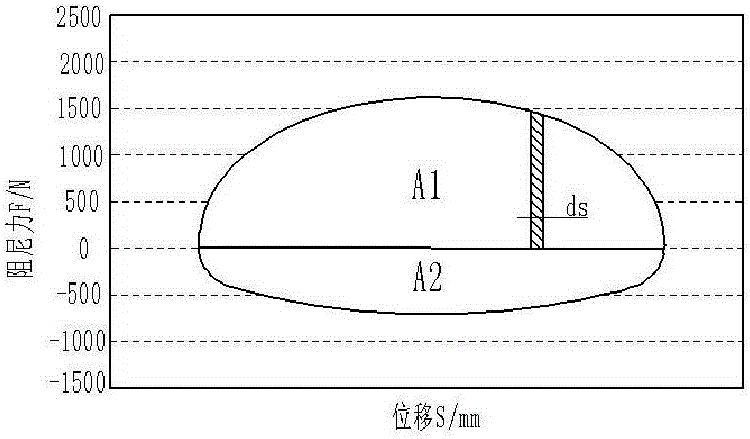

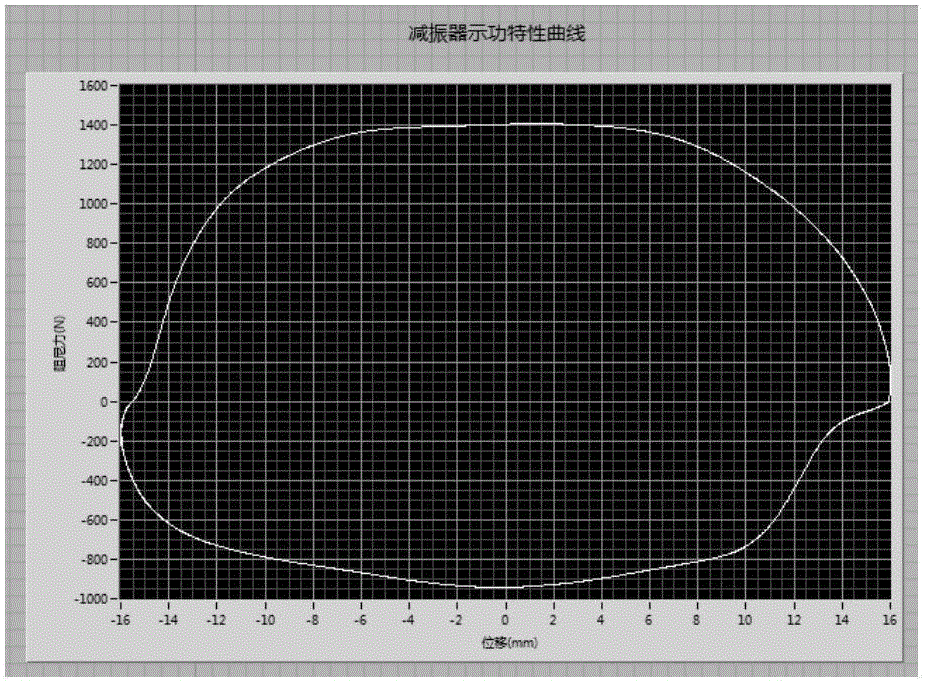

A technology of automobile suspension and energy characteristics, which is applied in the direction of vehicle suspension/shock absorbing mechanism testing, etc. It can solve problems such as rough automatic identification function, unfavorable mass production and testing of shock absorbers, and inability to reflect the damping characteristics of shock absorbers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0089] Embodiment Automobile suspension shock absorber energy characteristic testing system,

[0090] Such as Figure 6 and 7 The shown includes a frame body, a crank-link slider mechanism arranged on the frame body to generate sinusoidal motion, a fixture 4 for fixing the upper ring of the shock absorber 5 and a lower installation for fixing the lower ring of the shock absorber 5 during testing Bearing 6, speed sensor 9, and force sensor for measuring the damping force; the described crank-link slider mechanism is used to realize the reciprocating motion of the stretching and compression strokes of the shock absorber 5, and has a crank 10, the crank 10 One end is fixed on the frame body, and the other end of the crank 10 is connected with the bottom end of the crank connecting rod 8, and the crank connecting rod 8 can move circumferentially around the other end point of the crank 10; The mounting support 6 is connected so as to drive the shock absorber 5 to move up and down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com