Integrated inside and outside calipers

An integrated technology of internal and external calipers, applied in the field of measuring tools, can solve problems such as inability to meet the direct and effective requirements of measurement, difficulty in ensuring measurement accuracy, and single function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

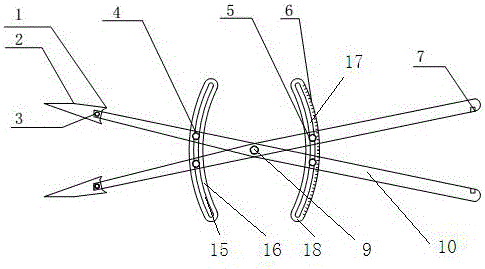

[0020] Below in conjunction with accompanying drawing, this technology is further described:

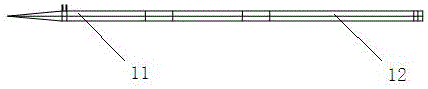

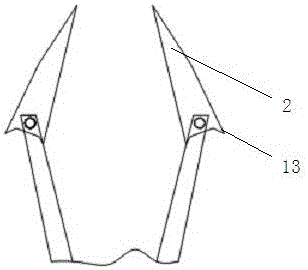

[0021] see figure 1 , figure 2 As shown, an integrated internal and external caliper includes a pair of pliers arms 10 symmetrically arranged and cross-hinged by a rotating pin 9. Each pliers arm 10 is a clamping section 11 on one side of the rotating pin 9, and a reading section on the other side. Section 12; the end of the clamping section 11 is provided with a chuck 2 that can be adjusted in a plane determined by a pair of pliers arms 10 and the included angle with the pliers arms 10, and the two chucks 2 with pointed ends are symmetrically arranged at the front end, and the chucks 2 Inner card when tilted inward (see image 3 shown), when the card head 2 is tilted outward, it is a wild card (see Figure 4 shown); in the reading section 12 is also provided with a reading device.

[0022] The thickness of the pliers arm 10 is constant, and the thickness of the pliers arm 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com