A method for laying exterior wall bricks

A laying method and wall brick technology, which can be used in construction and building construction, etc., can solve the problems of high labor intensity, difficulty in forming automatic laying effect, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

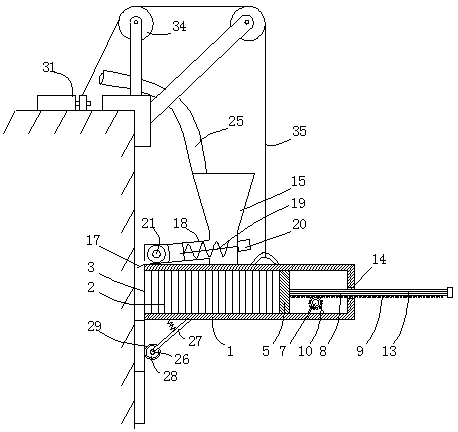

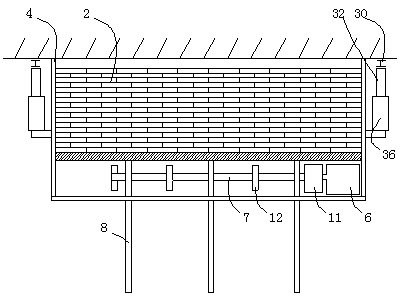

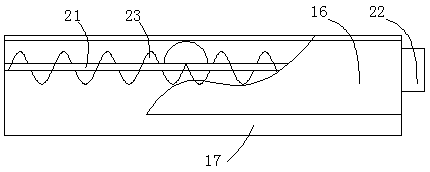

[0040] Embodiment: A method for laying exterior wall bricks, which is characterized in that the wall bricks are arranged vertically in a whole row, and then the rows of wall bricks are placed side by side from front to back according to the actual laying sequence from bottom to top. In a wall tile storage box with an outlet at one end and the wall tile laying surface is facing the outlet, so that the wall tile storage box outlet is facing the paved wall surface, the wall tile storage box is controlled to gradually lift, and during the lifting process, the wall tile storage box exit After smearing slurry on the front wall to achieve plastering, control the entire row of wall bricks to be pushed out and fit onto the applied slurry to complete the laying. In this way, the wall tiles can be laid in a row, which greatly improves the efficiency of wall tile laying.

[0041] Specifically, in this embodiment, the following automatic laying machine for wall tiles is used to realize the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com