A low pressure injection molding magnetic proximity switch

A magnetic proximity switch, low-voltage injection molding technology, applied in magnetic field/electric field switches, electrical switches, electrical connections of contacts, etc., can solve the problem of poor weather resistance and reliability of magnetic switches, and the connection structure of reed switches and leads is not fully considered. Stability and other issues, to achieve the effect of high electrical connection strength, improved electrical stability, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

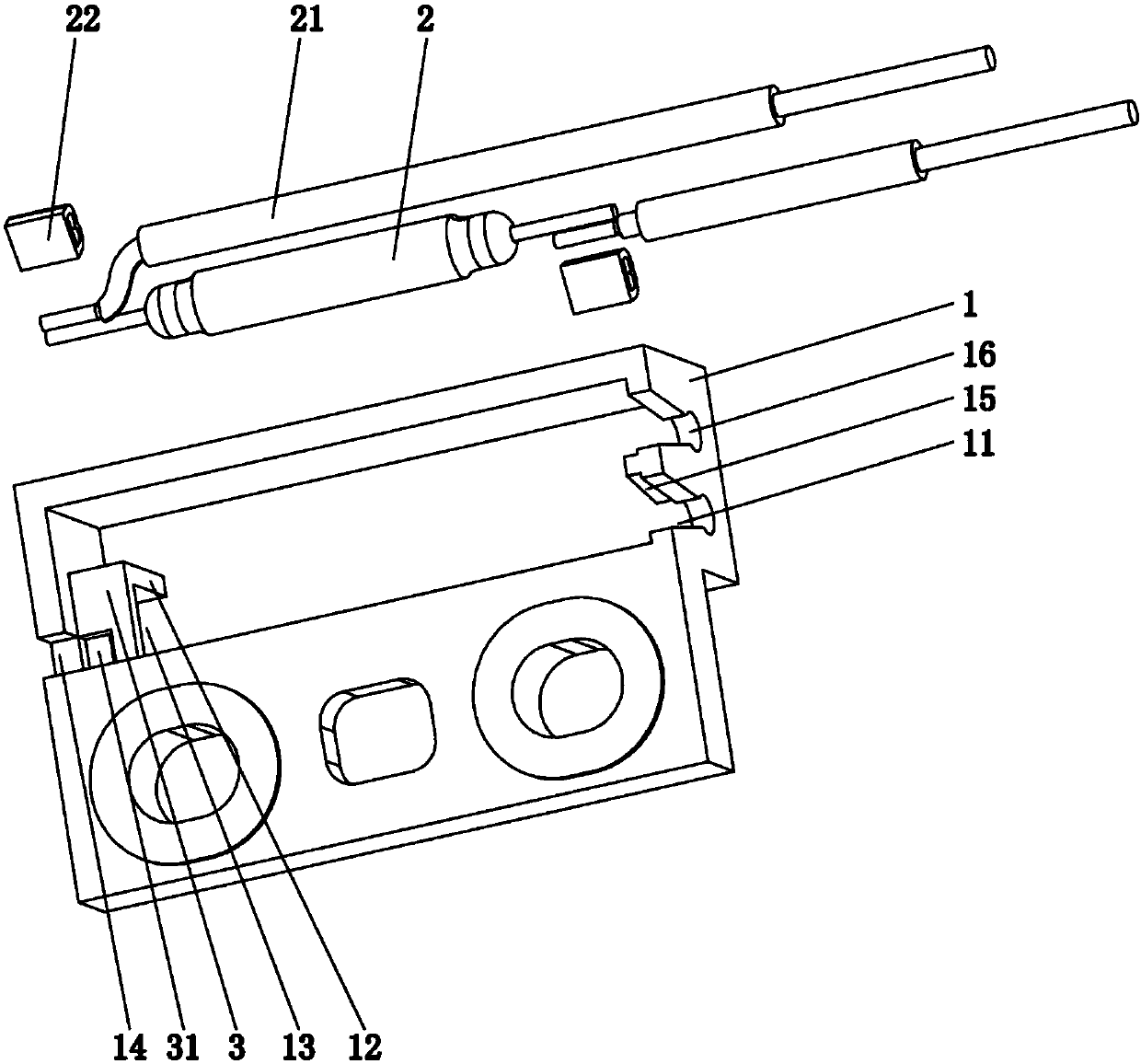

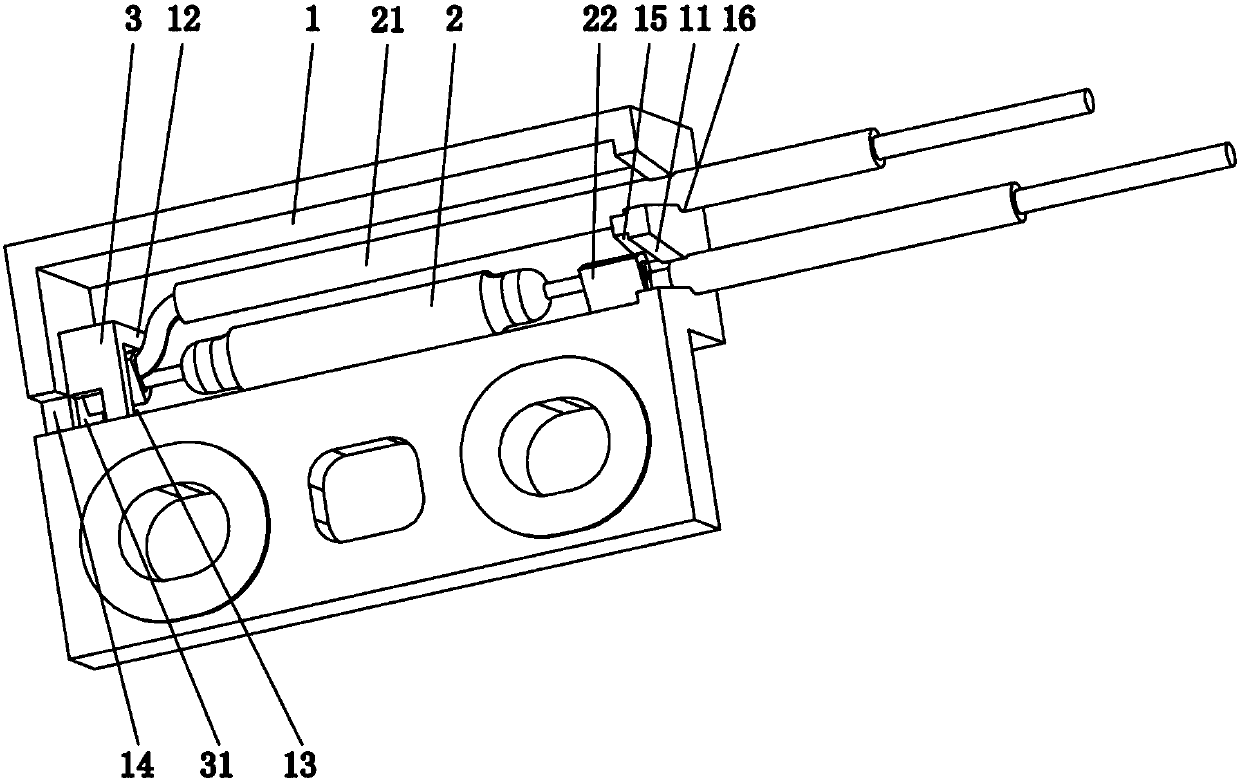

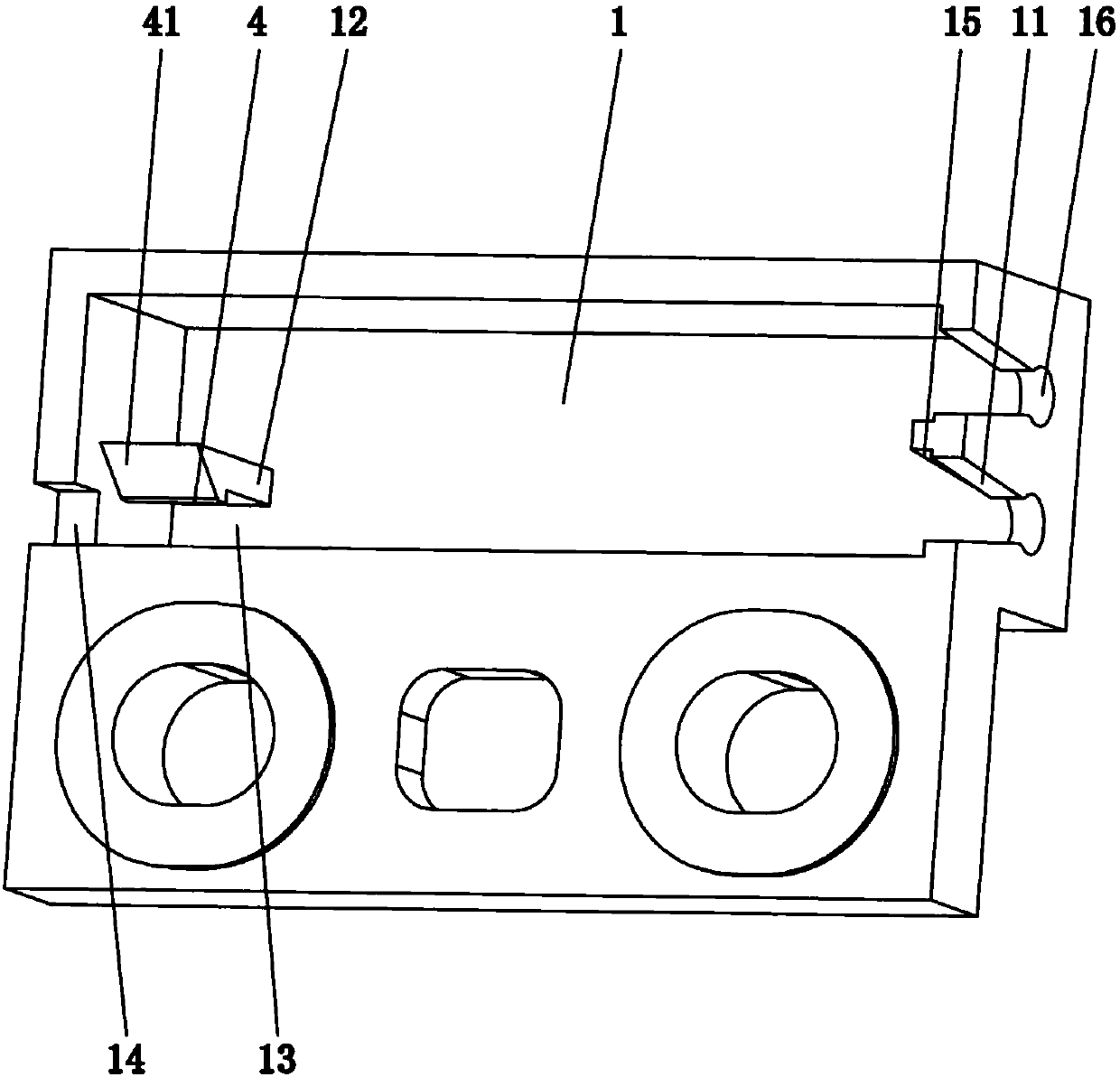

[0021] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

[0022] like Figure 1-2 As shown, a low-voltage injection-molded magnetic proximity switch according to the present invention includes a plastic box 1 with an opening at the upper end, a reed switch 2 and an incoming and outgoing lead wire 21, and two threading grooves are arranged on the right end wall of the plastic box 1 11. The inner side of the left end wall of the plastic box 1 is provided with a fixed line gusset 12, and the fixed line gusset 12 cooperates with one of the side walls of the plastic box 1 to form a fixed line opening 13; The two pins are electrically connected, and one of the pins of the reed switch 2 is fixed in the fixed line opening 13, and the incoming and outgoing lead wires 21 are respectively drawn laterally from the corresponding threading groove 11; the other pin of the reed switch 2 passes through the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com