Multifunctional material separating work table

A workbench, multi-functional technology, applied in the field of foundry, can solve the problems of single function, unable to meet the various needs of foundry production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

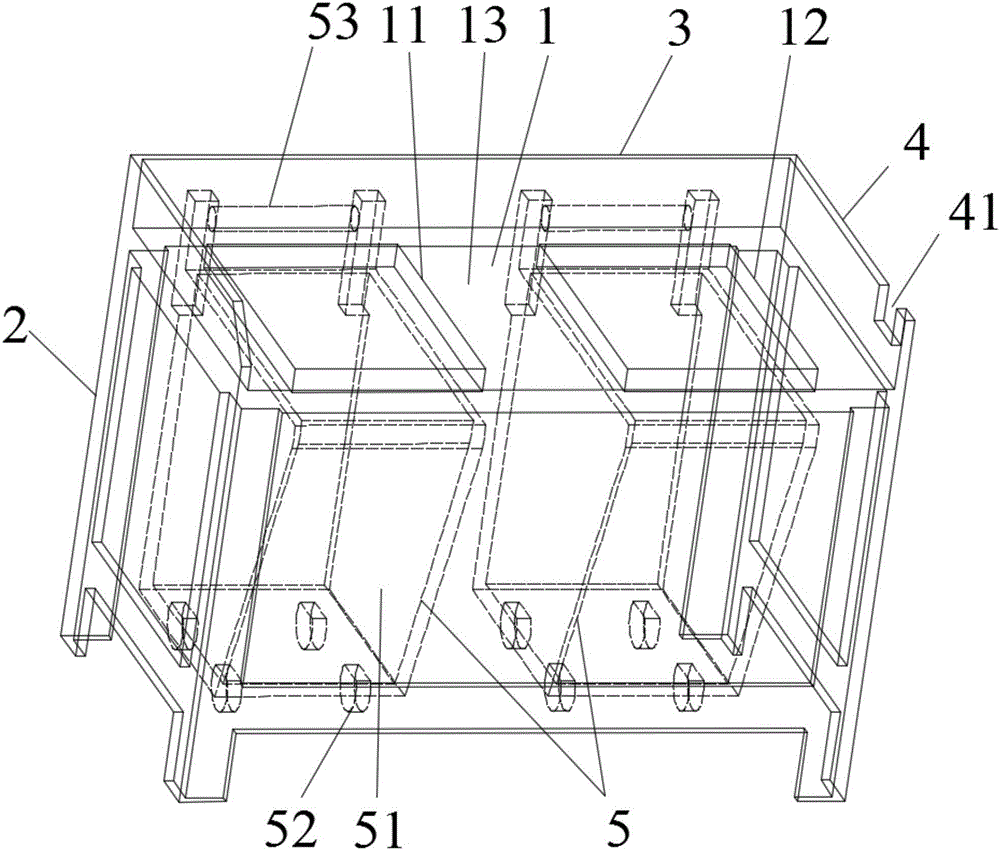

[0012] like figure 1 As shown, the multi-functional material distribution workbench includes a workbench 1; the workbench 1 is erected on the support frame 2, the rear side of the workbench 1 is provided with a rear baffle 3, and the side is provided with a side baffle 4 ; The side baffle 4 on the right side of the worktable 1 is provided with a material handle inspection tool port 41; the worktable 1 is provided with a feeding cart 5; the feeding cart 5 is composed of a box body 51 and wheels 52; The rear side of the box body 51 is provided with a handle 53 at the upper position; the left side of the work surface 1 is provided with a slag bag distribution port 11, and the right side is provided with a material handle distribution port 12; the slag bag distribution port 11 And feed handle distributing port 12 is provided with plank 13; Two skips 5 correspond to slag bag distributing port 11 and feed handle distributing port 12 respectively; 53 is located at the back side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com