One-way valve and food processer using one-way valve

A one-way valve, valve stem technology, applied in one-way valve. It can solve the problems of blockage of the water injection hole and inconvenient cleaning of the water injection hole of the mixing cup, so as to achieve the effect of convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

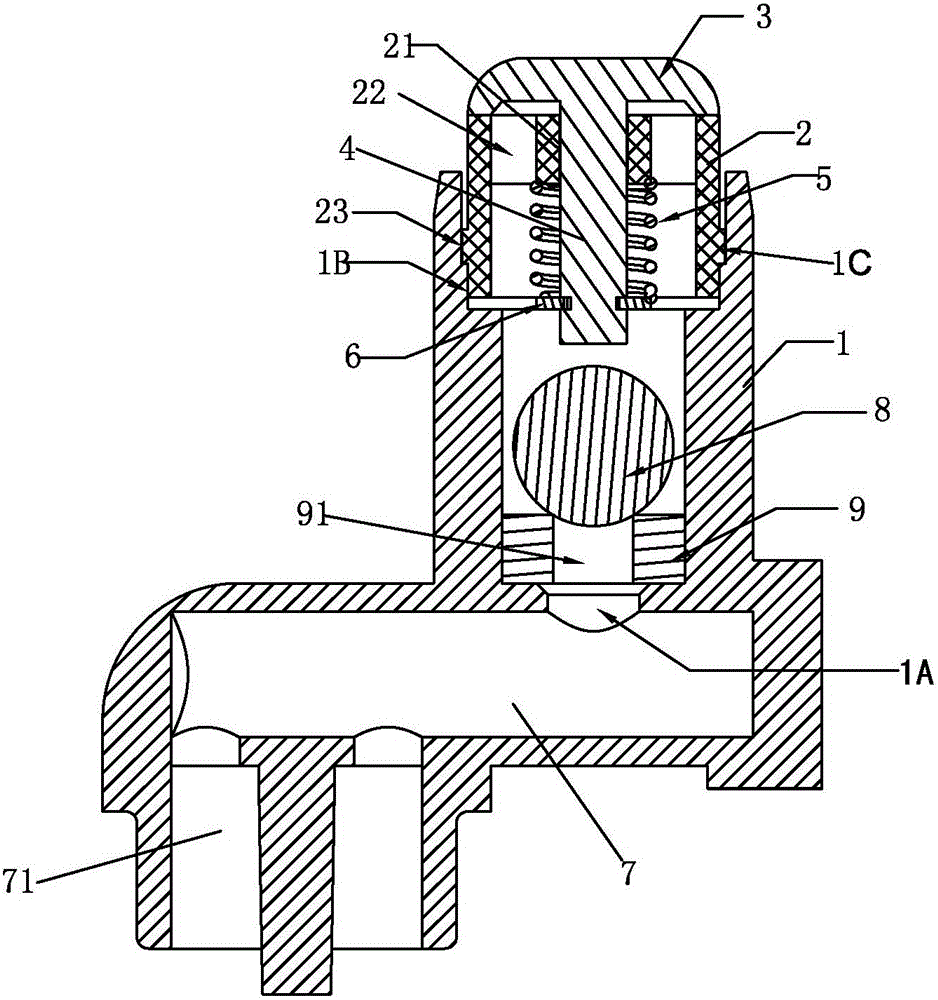

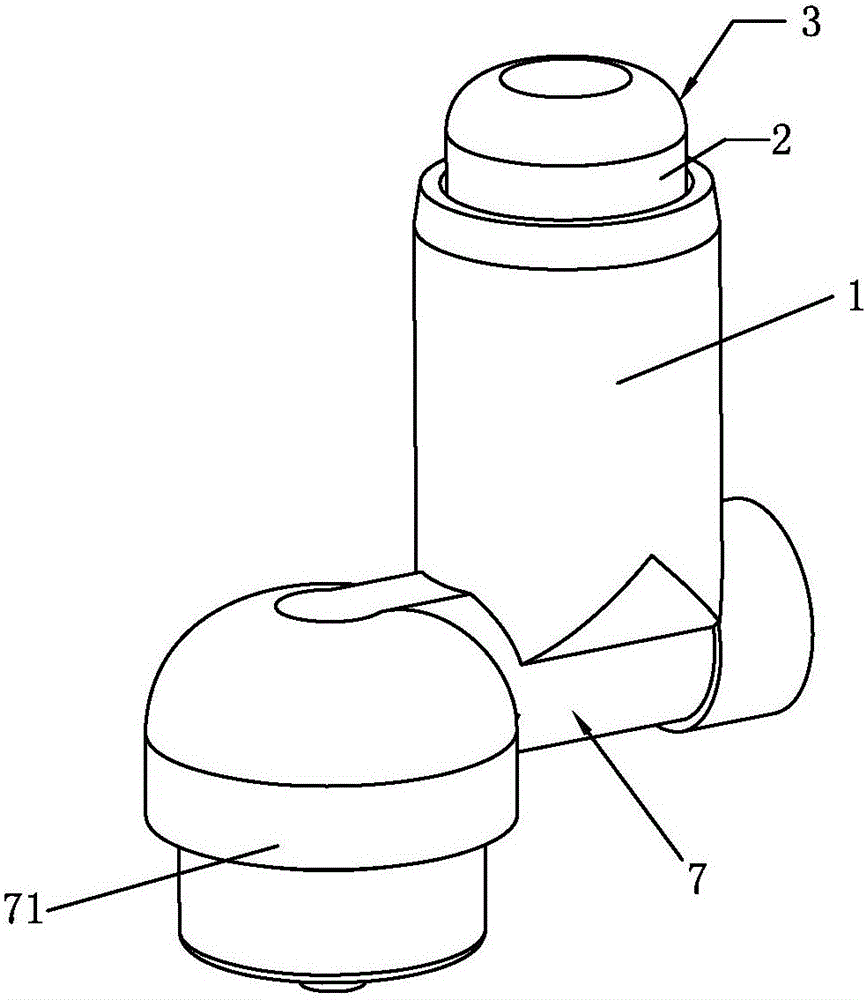

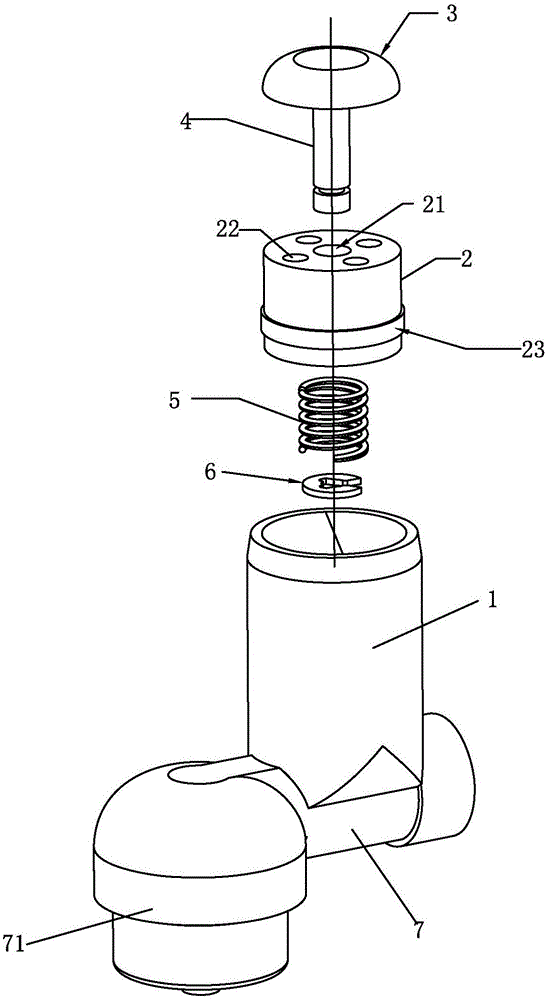

[0028] Such as figure 1 , figure 2 , image 3 Shown, a kind of one-way valve, it comprises valve body 1, spool 2, bonnet 3, valve stem 4, pressure spring 5 and jump ring 6; The center is connected with the top end of the valve stem 4, and the valve cap 3 and the valve stem 4 are integrally formed;

[0029] The spool 2 is hollow cylindrical, and the spool 2 includes a valve stem channel 21 located in the center and a liquid hole 22 surrounding the valve stem channel;

[0030] The lower end of the valve body 1 is provided with a liquid inlet pipe 7, and the axis of the liquid inlet pipe 7 is perpendicular to the axis of the valve body 1; there is a liquid guide hole 1A at the intersection of the liquid inlet pipe 7 and the valve body 1; the upper opening of the valve body 1 There is a spool cavity 1B at the end;

[0031] The valve core 2 is fixed in the valve core cavity 1B and connected with the valve body 1, the valve cap 3 passes through the valve core 2 through the valv...

Embodiment 2

[0040] Such as Image 6 with Figure 7 As shown, a cooking machine includes a host 11, a stirring cup 12, a water storage tank 13, a water pump 14, a water heater 15, a water pipe connector 16 and a one-way valve. The stirring cup 12, the water storage tank 13, and the water pipe connector 16 The water heater 14 and the water pump 15 are arranged in the bottom case 111 of the main machine 11 respectively, and the water storage tank 13, the water pump 14, the water heater 15 and the water pipe connector 16 are connected through the pipeline Connected in turn to form a water delivery system, the stirring cup 12 includes a circular chassis 121 located at the bottom of the stirring cup, characterized in that: the one-way valve is vertically installed in the installation hole 1211 on the circular chassis 121 of the stirring cup 12, and the valve The body 1 is embedded in the installation hole on the circular chassis 121 to cooperate with the liquid seal, the top of the valve body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com