Tire-holding automobile carrier

A car carrier and wheel-holding technology, which is applied in the field of wheel-holding car carriers, can solve the problems of multiple drives, potential safety hazards, damage to cars, etc., and achieve the effect of simple and reliable structure and good synchronization of actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

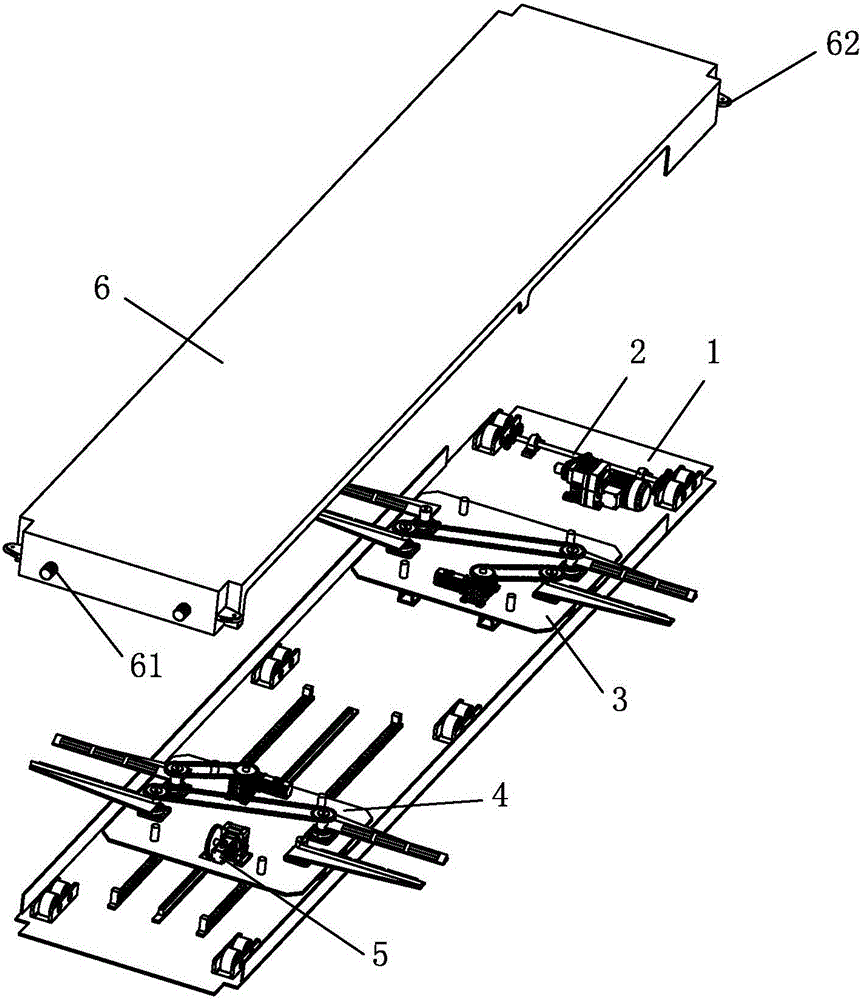

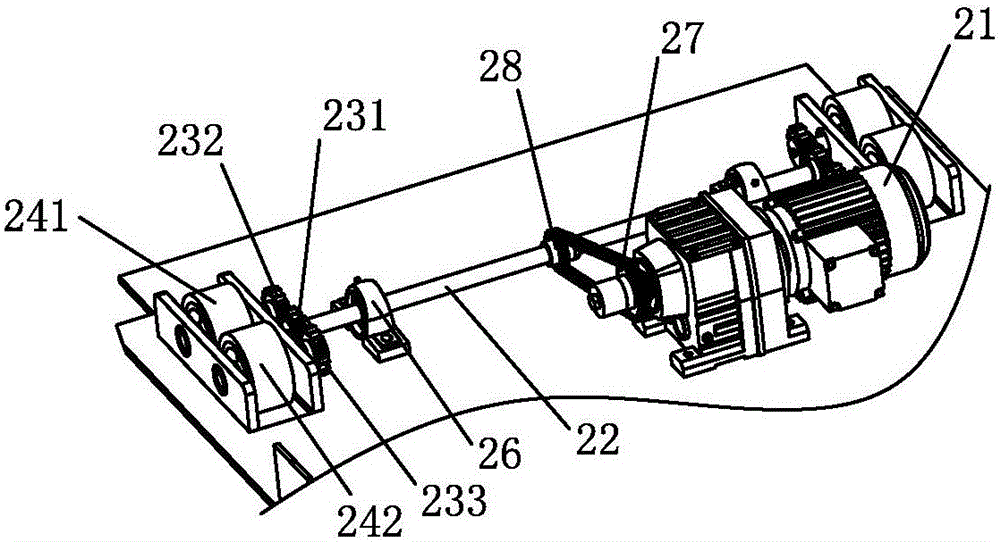

[0026] like Figure 1 to Figure 7 As shown, the wheel-holding type vehicle carrier of the present invention includes an underframe 1, a running mechanism 2, a clamping mechanism and a wheelbase adjustment mechanism 5. The underframe 1 is mainly used for installing various components, and is welded by steel plate profiles. The installation positions of the traveling mechanism 2, the clamping mechanism and the wheelbase adjusting mechanism 5 are reserved. The traveling mechanism 2 is used to drive the carrier forward or backward, which is convenient for handling the car; the clamping mechanism includes a first clamping mechanism 3 and a second clamping mechanism 4, and the first clamping mechanism 3 and the second clamping mechanism 4 have the same structure, Both are used to hold up automobile tires, the difference is that the first clamping mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com