Edible mushroom bottle combing device and edible mushroom bottle pressing equipment

The technology of a carder and a fungus bottle is applied in the field of edible fungus production equipment, which can solve the problems such as the deviation of the bottle mouth, the inability to press down the raw materials, and the machine stop, so as to achieve the effect of ensuring the sequence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

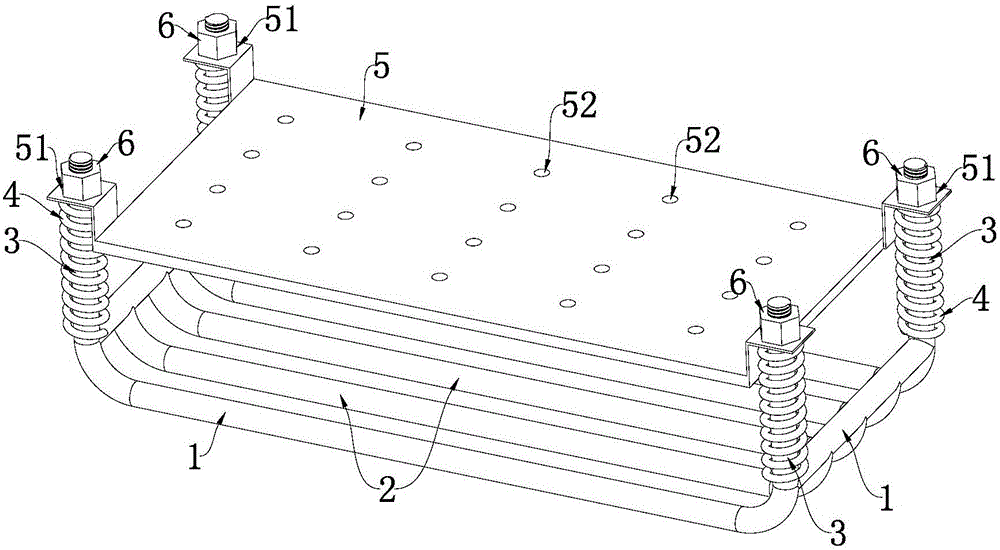

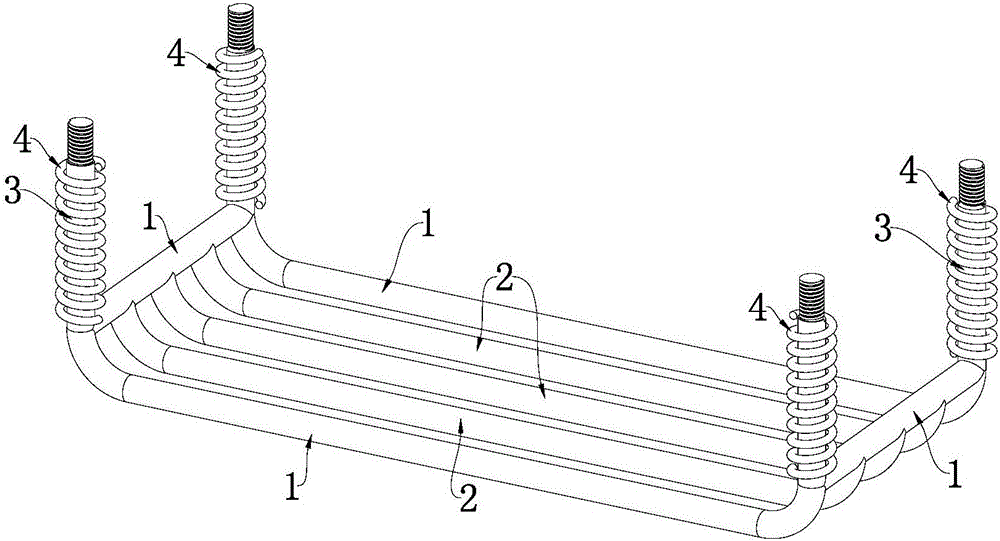

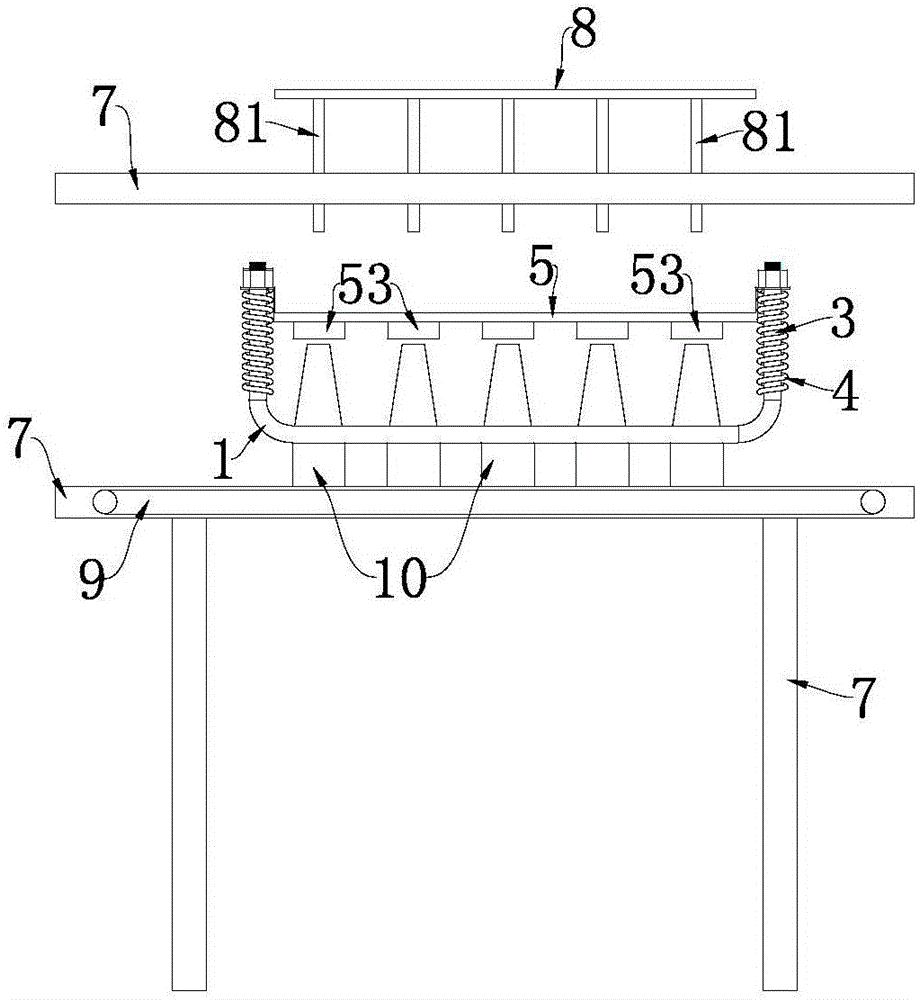

[0026] Such as Figure 1-2 As shown, a kind of edible fungus bottle carder of the present invention comprises: outer frame 1, top plate 5 and return spring 4; Wherein outer frame 1 is rectangular structure, is respectively vertically provided with a connecting rod at four corners of outer frame 3. A plurality of crossbars 2 are arranged side by side in the outer frame 1, wherein the distance between adjacent crossbars 2 is smaller than the maximum diameter of the bottle; four connecting holes 51 are opened on the top plate 5; the top of each connecting rod 3 Correspondingly pass through the connecting hole 51 on the top plate 5, and a clip 6 is provided at the top of the connecting rod 3 to hang the connecting rod 3 on the top plate 5; the return spring 4 is sleeved on the connecting rod, and the return spring The two ends of 4 are in elastic stress contact with the outer frame 1 and the top plate 5 respectively.

[0027] Specifically, the connection relationship between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com