Intelligent appearance defect high-speed detection machine

A detection machine and detection mechanism technology, applied in sorting and other directions, can solve the problems of high price, complex structure, low efficiency, etc., and achieve the effects of timely feeding, high coding position accuracy, and ensuring high speed and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

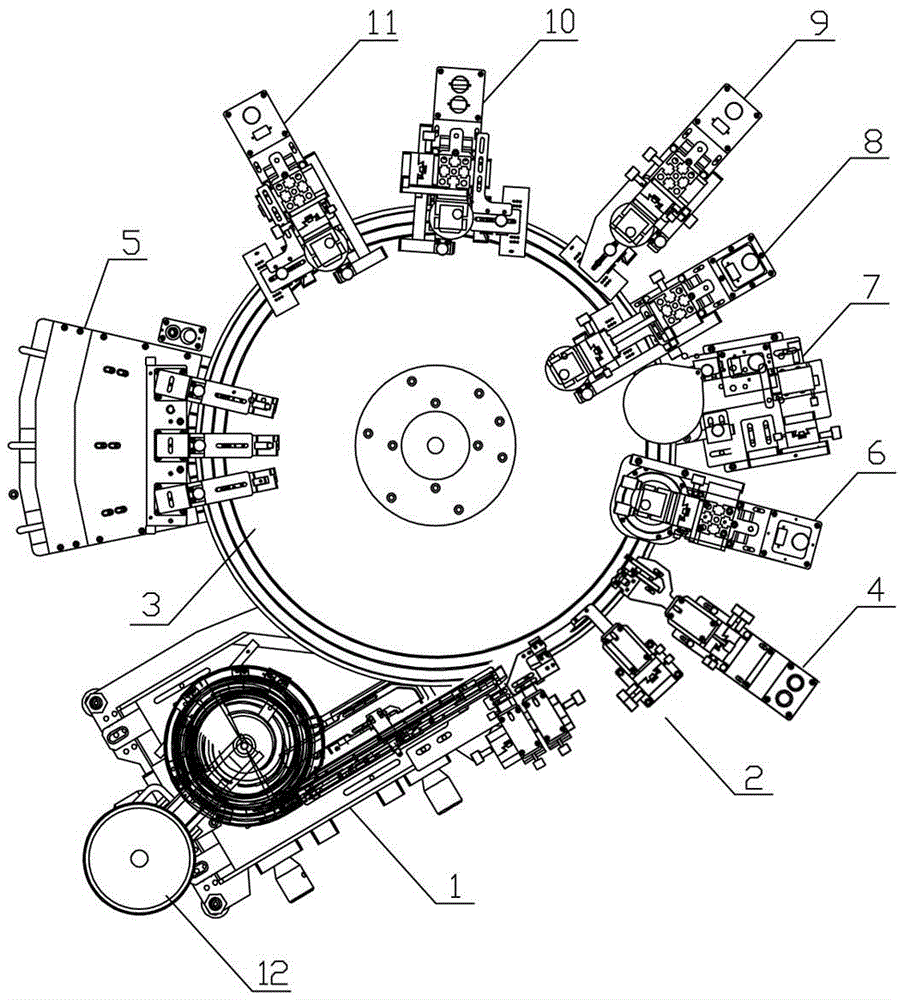

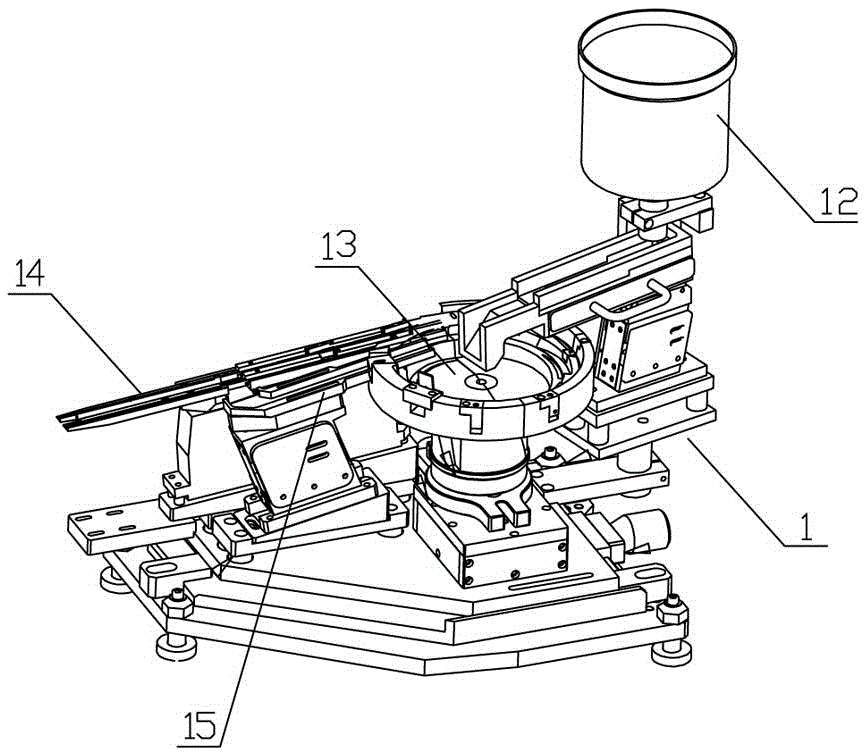

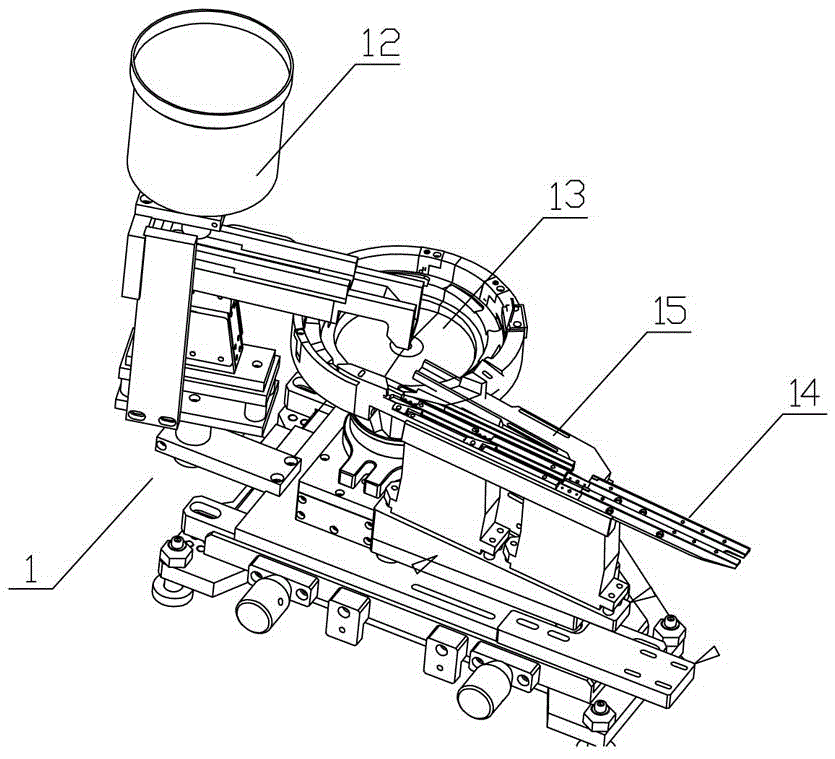

[0048] figure 1 It is a top view diagram of an intelligent high-speed defect detection machine of the present invention, which is provided with a feeding mechanism, a material guiding mechanism, a transparent turntable conveying mechanism, a detecting mechanism, a sorting mechanism and a control system. The feeding mechanism includes a feeder, a disc feeder, a linear feeder and a feeder. It is also equipped with a material detection sensor that can control the feeding of the feeder. The linear feeder is provided with a return port connected to the feeder. The outlet of the device is connected to the disc feeder, see figure 2 , 3 shown.

[0049] The transparent turntable conveying mechanism is composed of a servo drive system, a coupling, a bearing mount, and a high-transparency transparent glass turntable, see Figure 4 shown. The detection mechanism includes a position detection unit, a high-speed CCD camera unit, a focus adjustment lens, and an ultra-high-brightness lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com