Ball hydraulic lifting operation platform

A working platform, hydraulic technology, applied in the direction of lifting frame, lifting device, conveyor objects, etc., can solve the problems of no brake control, unable to achieve orders and prohibitions, etc., to achieve the effect of convenient implementation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

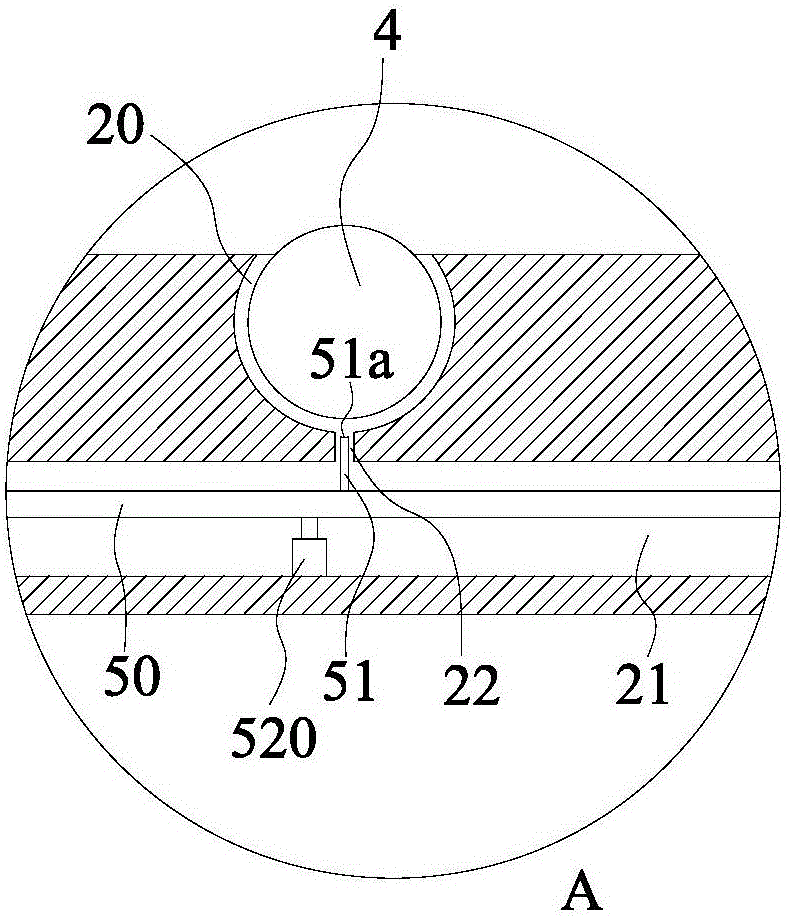

[0023] Such as figure 1 with figure 2 As shown, the ball hydraulic lifting operation platform of this embodiment includes a base 1, a carrying platform 2, and a lifting mechanism 3, wherein a plurality of embedding holes 20 are provided on the upper surface of the carrying platform 2, and the lifting operation platform also includes embedded parts respectively. The balls 4 which are free to rotate in the slot hole 20 and the braking device 5 used to stop the rotation of the braking balls 4 , wherein the upper surfaces of a plurality of balls 4 are flush with each other, and the braking device 5 is hidden in the carrying platform 2 .

[0024] A dark groove 21 is provided inside the carrying platform 2 , and a through hole 22 communicating with the dark groove 21 is arranged at the bottom of each embedding hole 20 .

[0025] The brake device 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com