Weftless bandage tape compression cutting method

A technology of no weft belt and pressing block is applied in the field of inspection, which can solve the problems of inability to detect and test, and achieve the effects of simple loading and unloading method, reliable positioning, and easy assembly.

Active Publication Date: 2016-07-20

HARBIN

View PDF7 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to overcome the above problems, the present invention provides a method of compressing and shearing the latitude-free tape to meet the product quality requirements, avoid the phenomenon that the product cannot be detected and tested after the product is manufactured, and realize the purpose of detecting individual products one by one, so as to process qualified products and meet product quality requirements. Require

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

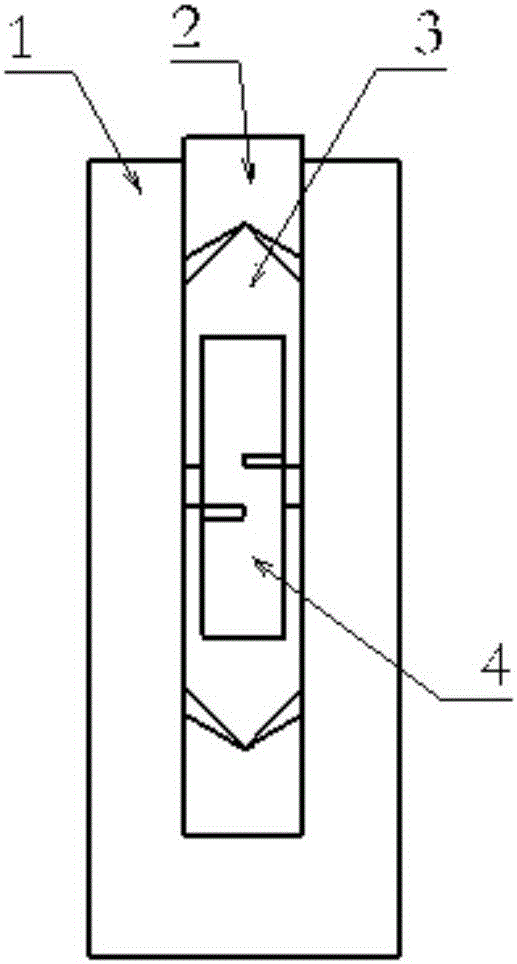

[0018] The shape of the sample is a cuboid, and the dimensions of length X width X height are 25X7X10. There are two long slots in the length direction. The material is glass fiber composite material. 2. Then, place the sample on the pressing block 2, then place the positioning block 3 and the pressing block 2 in turn, and realize the effect of compressing and shearing the sample without weft tape by manipulating the tensile machine.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to detection technology and relates to a weftless bandage tape compression cutting method. The method includes that a split positioning structure which can effectively contact with a product sample is adopted; a special clamp is designed, a tensile machine is utilized for a compression experiment of a weftless bandage tape, namely a glass fiber product after being cured and formed, the problem that inside tissue cannot be detected after rotors of airplane products are manufactured well is solved, and the rotors after being formed are ensured to meet quality requirements on the products. The clamp is safe and reliable to mount, simple to demount and convenient to assemble, angles of parts in the clamp are set to enable stressed direction to accurately ensure fiber direction of a testing sample. The clamp has a rigid connection function and meets the quality requirements on the rotors of the airplane products. The objectives of safety and reliability of the glass fiber product in the rotors are achieved, and requirements on integral quality of rotor products are met. The structure is reliable in positioning, firm in clamping and simple and convenient to operate.

Description

technical field [0001] The invention belongs to detection technology and relates to a method for compressing and shearing latitude-free tapes. Background technique [0002] When manufacturing aircraft products, it is necessary to test the manufactured products. Since the rotors of aircraft products are made of composite materials, composite materials are composed of carbon fiber, glass fiber, rigid foam, glue and other materials. The internal structure cannot detection. Therefore, individual products need to be tested one by one. This requires a special set of fixtures. At present, the glass fiber sample single product inspection uses the vise as a tool, and the vise cannot control the size of the force, and the operation is inconvenient to affect the normal production. The phenomenon of being unable to detect and test after the rotor of the aircraft product is manufactured can realize the purpose of detecting individual products one by one and meet the product quality re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/04G01N3/24

CPCG01N3/04G01N3/24G01N2203/0012G01N2203/0025G01N2203/0282G01N2203/04

Inventor 凌寿刚

Owner HARBIN

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com