a soil repair knife

A blade and blade back technology, applied in the field of geotechnical testing, can solve the problems of poor operation flexibility of the soil trimmer, interference with the normal use of the blade, and poor leveling effect of the soil trimmer, so as to facilitate stable control of the scraping angle and strength, and reduce hand-held shaking. , to meet the effect of flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

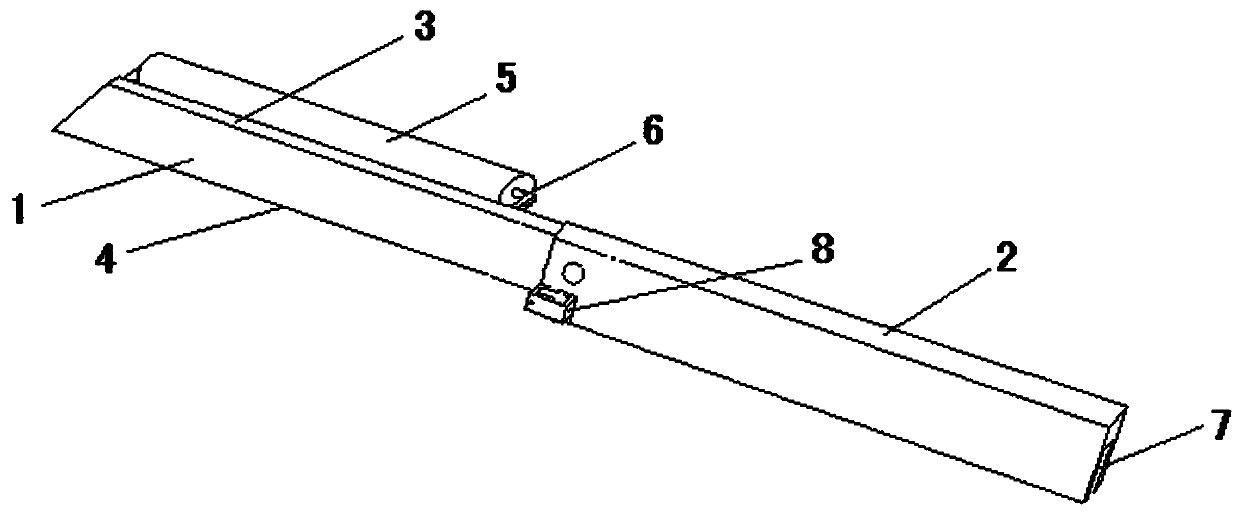

[0033] figure 1 It is the front view of the soil trimming knife provided in this embodiment. Such as figure 1 As shown, the soil trimming knife provided in this embodiment includes a blade 1; a roller structure, which is installed on one side of the blade 1 and does not interfere with the scraping action of the blade 1, and the roller structure has a function for rolling Roller to level the surface of the sample.

[0034] By installing a roller structure on one side of the blade 1, the roller structure not only does not interfere with the scraping action of the blade 1, but also can roll the surface of the sample to be leveled, and the smooth curved surface of the roller can evenly contact the surface of the sample. Smooth rolling, the operator holds the soil repairing knife and alternately repeats the action of blade 1 scraping and roller rolling to complete the leveling of the sample surface. Compared with the scraping plane of the triangular scraper, the rolling surface o...

Embodiment 2

[0045] As an alternative to the first embodiment, this embodiment provides a soil repairing knife. The difference between the soil repairing knife and the first embodiment is that:

[0046] In the soil trimming knife provided in this embodiment, the roller structure is fixedly installed on the side surface of the blade through a fixed support structure, one end of the fixed support structure is connected to the roller structure, and the other end is connected to the blade of the blade. side surface connection.

[0047] Specifically, the fixed support structure includes a pair of support rods arranged correspondingly at intervals on one side surface of the blade along the extending direction of the length of the blade, and one end of each support rod is rotatable with the roller structure through a fixed shaft. connected so that the roller can rotate freely, and the other end is welded or bolted to the side surface of the blade.

[0048] It should be noted that the pair of sup...

Embodiment 3

[0050] As an alternative to the first embodiment, this embodiment provides a soil repairing knife. The difference between the soil repairing knife and the first embodiment is that:

[0051] In the soil trimming knife provided in this embodiment, the drum structure includes two cylinders with the same diameter, and the two cylinders are arranged coaxially above the knife back of the blade through a support structure, and the support structure is a T-shaped support frame , the lower end of the vertical part of the T-shaped support frame is connected to the back of the knife, and the two ends of the horizontal part of the T-shaped support frame are respectively inserted into the shaft holes of the corresponding end faces of the two cylinders, so that the two circles The barrels can rotate freely around the horizontal part of the T-shaped support frame as the axis.

[0052] It should be noted that the T-shaped support frame can be the movable support structure described in Embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com