Sliding straight line drawing device and multi-line stakeout method using the device

A sliding, straight-line technology, applied in workshop equipment, manufacturing tools, etc., can solve the problems of complex line drawing method, increase the error value of axis or edge, and large amount of ink, so as to improve the lofting efficiency, high efficiency, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

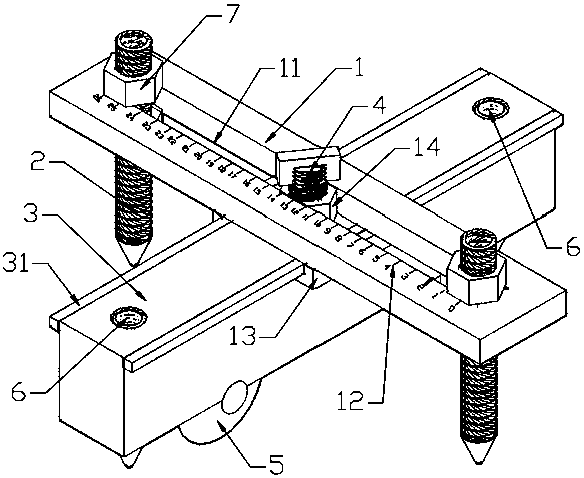

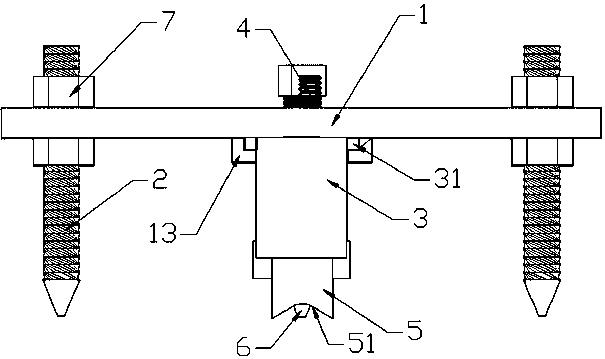

[0027] As shown in the figure, as shown in the figure, the sliding straight line drawing device provided by this embodiment includes a scale plate 1 with a transverse chute 11 in the middle, and two chute 11 are symmetrically arranged on the scale plate 1. An ink pen 2 that can be placed on the upper limit of the scale plate 1; a marking block 3 with a roller 5 at the bottom is provided under the scale plate 1, and the marking block 3 and the scale plate 1 are vertically intersecting, and the rollers The rolling paths of 5 are all perpendicular to the length direction of the chute 11; on the scale plate 1, the upper side and / or the lower side of the chute 11 are provided with a row of marking lines 12 for marking the length, and the starting and ending points of the marking lines 12 are is the start and end point of the chute.

[0028] If the reticle block 3 is fixedly arranged under the scale plate 1, a dead angle for drawing lines will occur because of the blocking of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com