Sand shooting device for core shooting machine

A technology of core shooting machine and sand shooting hole, which is applied in the field of core shooting machine, and can solve the problems of various specifications and models, inconvenient position adjustment, cumbersome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

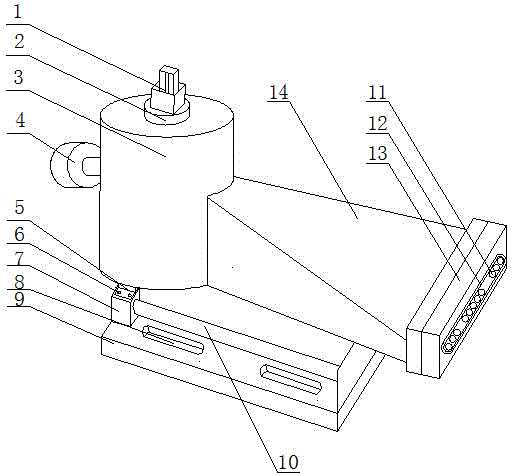

[0016] A sand shooting device for a core shooting machine, comprising a fixed seat 9, a horizontal sliding mechanism and a sand box assembly, the fixed seat 9 is used to connect with the core shooting machine; the horizontal sliding mechanism is arranged on the fixed seat 9; the sand box assembly is arranged on a horizontal sliding mechanism and can move left and right on the horizontal sliding mechanism; the sand box assembly includes the sand cylinder 3, the air valve 1 installed on the sand cylinder 3 through the mounting seat 2, the joint 4 for connecting the sand delivery pipe, and the sand cylinder 3 wall. The sand box 14 on the top and the sand mouth 13 that is connected on the sand box 14, the sand mouth 13 is provided with the shot hole 11 that communicates with the sand box 14.

[0017] In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com