Single-output-shaft hub-type DC brushless motor

A DC brushless motor and hub-type technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as damage, poor rim sealing, low assembly efficiency, etc., to ensure reliability in use, good sealing performance, and extended The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

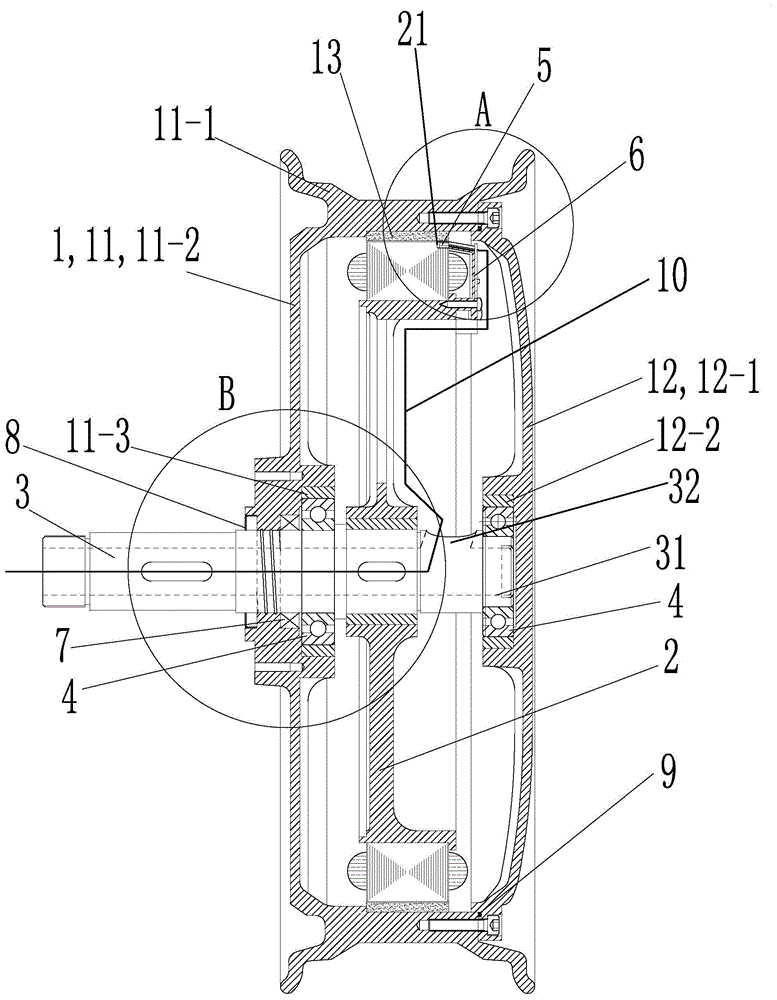

[0030] See Figure 1 to Figure 6 , the single-shaft hub-type brushless DC motor of this embodiment is mainly composed of a rotor 1, a stator 2, a connecting shaft 3, a bearing 4, a Hall element 5, a Hall element mounting frame 6, an oil seal 7, a dust-proof ring 8 and O-ring 9 components.

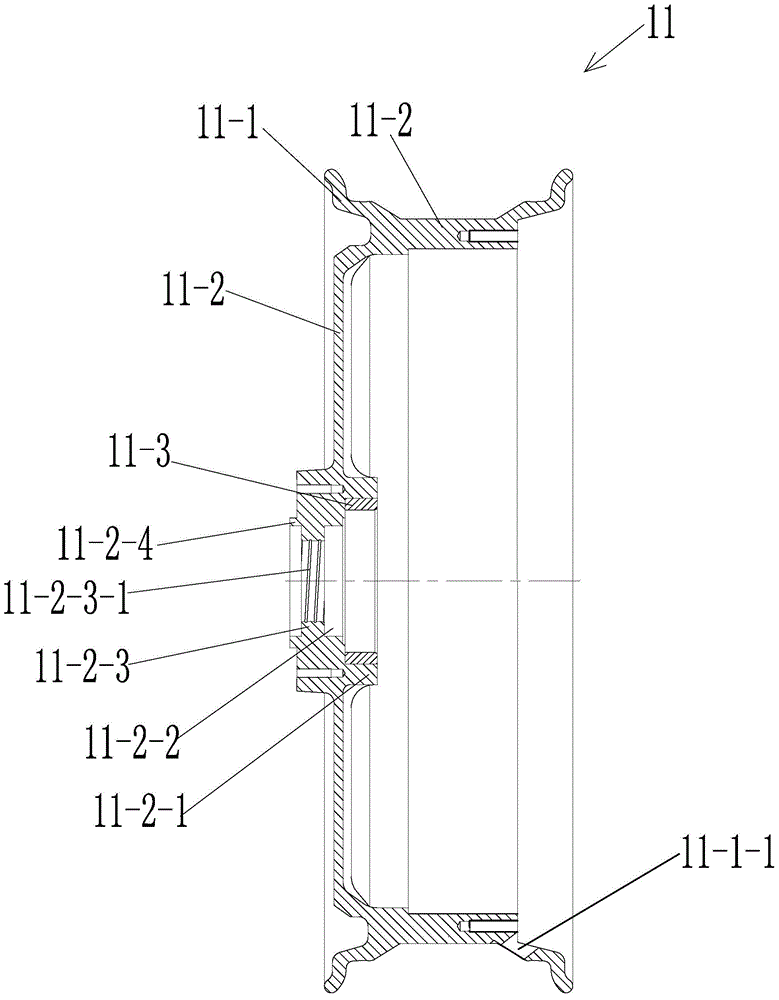

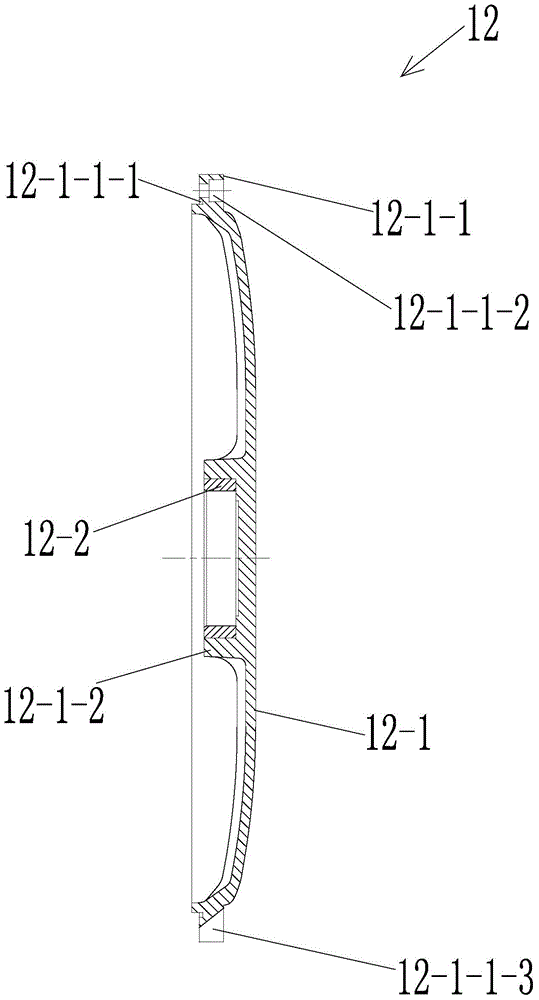

[0031] see figure 2 and image 3 , The rotor 1 is mainly composed of a first housing 11 , a second housing 12 and a magnetic steel 14 .

[0032] The first housing 11 is mainly composed of a rim 11-1, a spoke 11-2 and a bearing sleeve 11-3. The rim 11-1 and the spoke 11-2 are integrally formed, and move from the outside to the center along the radial direction of the first housing 11. These are the rim 11-1 and the spokes 11-2 in turn.

[0033] The rim 11-1 is an irregular ring; the outer inner wall of the rim 11-1 is the installation and connection part of the tubeless tire.

[0034] The spoke 11-2 is disc-shaped, and the spoke is integrally connected with the rim by its outer end sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com