Control device for main steam valve of horizontal version oil control type steam turbine

A control device and steam turbine technology, applied in the direction of valve device, valve operation/release device, valve details, etc., can solve problems such as danger, high labor intensity of operators, time-consuming and labor-intensive problems, so as to prevent accidents and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

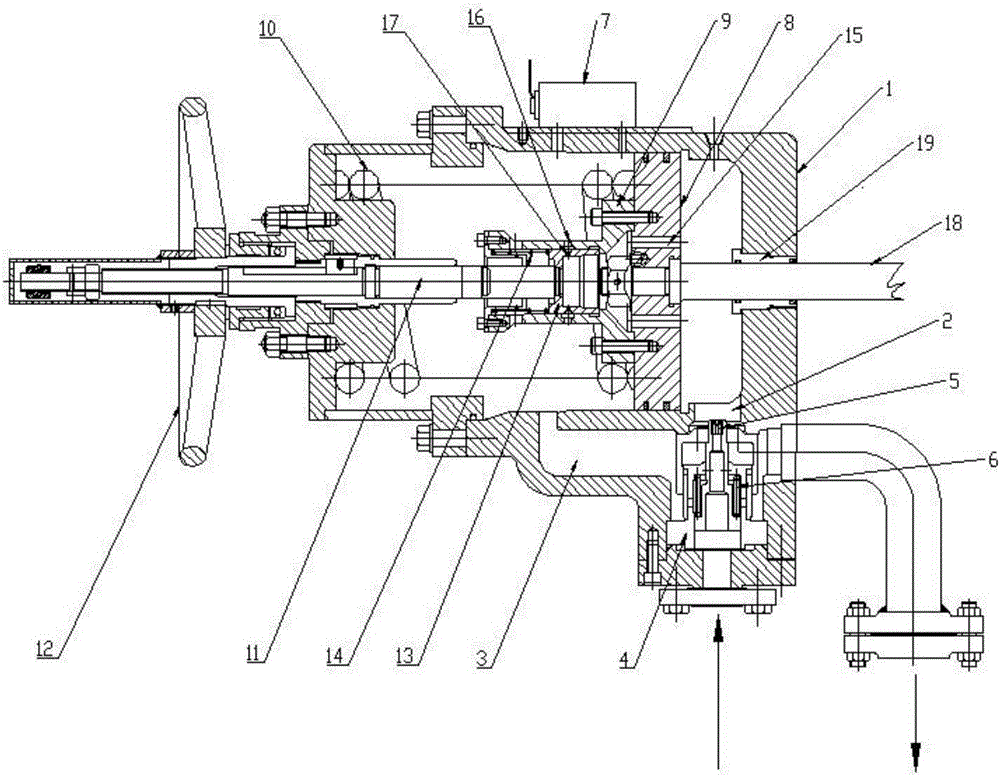

[0016] As shown in the figure, a horizontal oil-controlled steam turbine main steam valve control device includes an oil cylinder 1, an oil inlet 2 is provided at the left end of the side wall of the oil cylinder 1, and an oil return port 3 is provided at the right end of the side wall of the oil cylinder 1 , install the oil inlet assembly in the oil inlet 2 of the oil cylinder 1, the oil inlet assembly is composed of the oil inlet assembly body 4, the oil inlet assembly spool 5 inserted on the oil inlet assembly body 4 and connected to the oil inlet assembly The tension spring 6 is formed between the body 4 and the valve core 5 of the oil inlet nozzle assembly; a flexibility check valve 7 is installed on the side wall of the oil cylinder 1, and the oil inlet and the oil outlet of the flexibility check valve 7 are respectively located in the oil cylinder 1 The left and right ends of the side wall; the piston 8 is set in the oil cylinder 1, the control box 9 with the shaft hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com