Upper grip line tensioning device

A tensioning device and shoe upper technology, which is applied to footwear, shoe lasts, clothing, etc., can solve the problems of high labor intensity, shedding, and poor versatility of workers, and achieve the effect of improving the quality of the upper grip and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

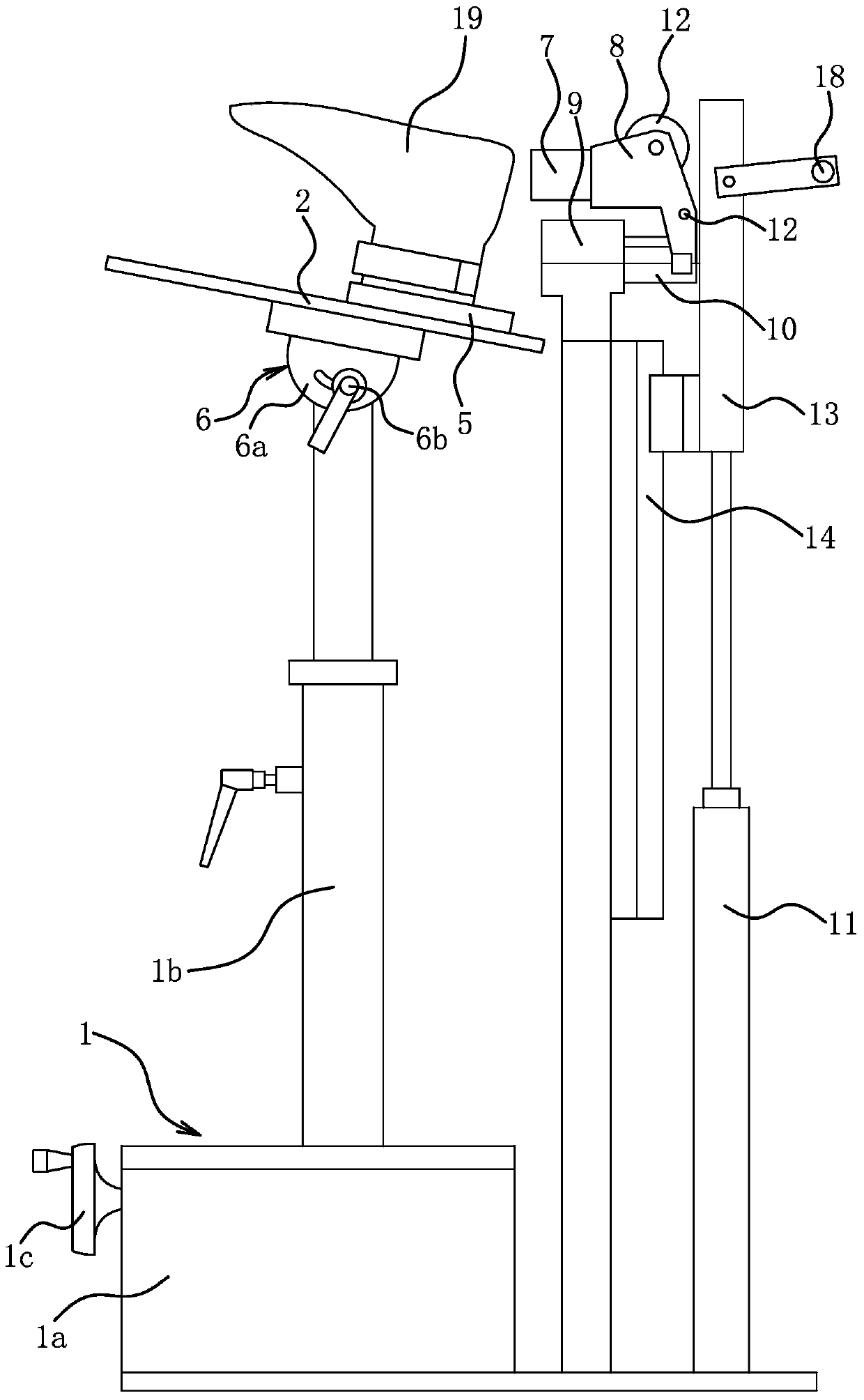

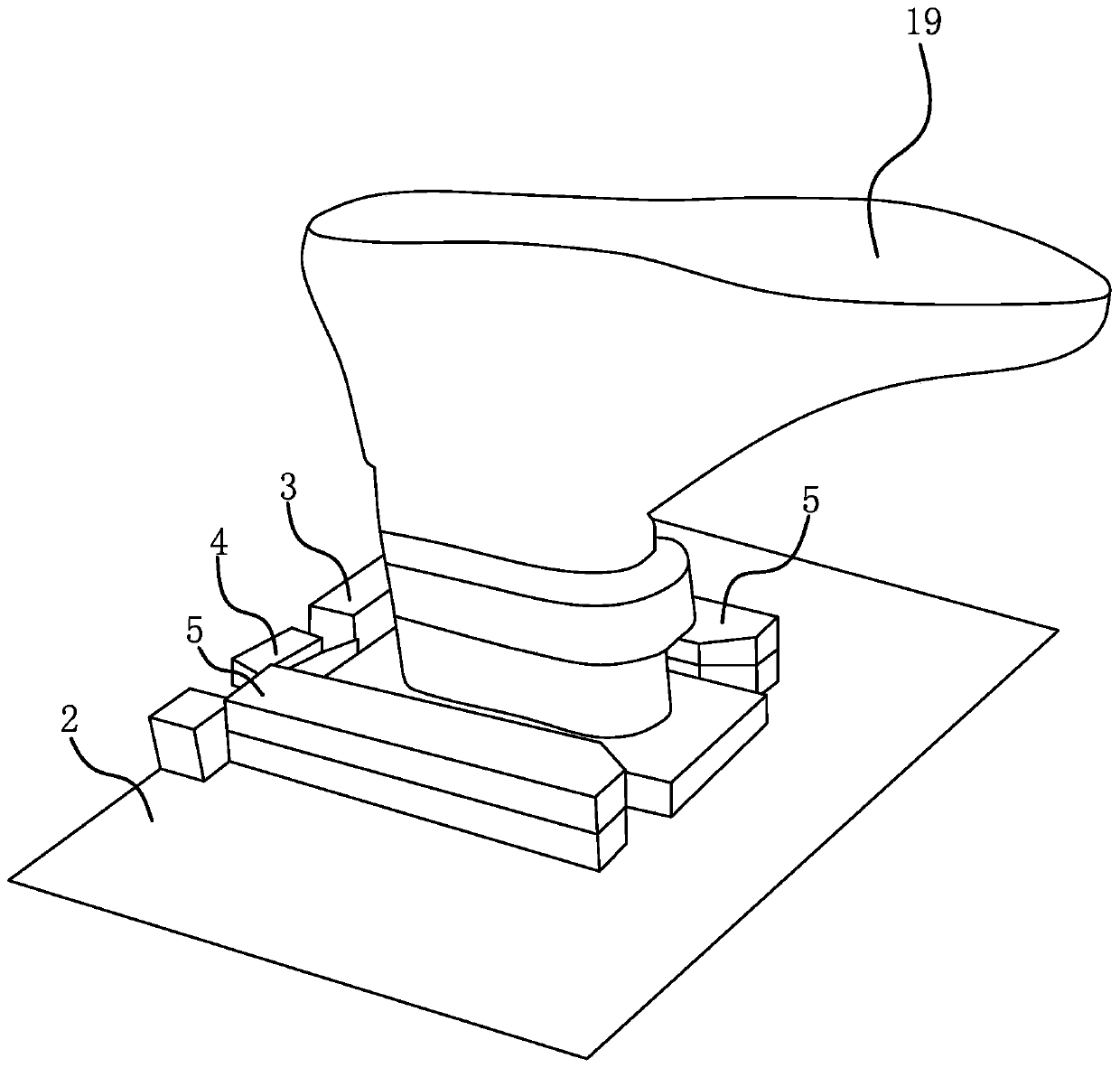

[0016] Such as Figure 1 to Figure 3 As shown, the shoe upper grasping upper line tensioning device includes a frame 1, a fixing seat 2 and a traction structure.

[0017] The frame 1 includes a base 1a and a telescopic rod 1b that can be adjusted in length vertically. The lower end of the telescopic rod 1b is connected to the base 1a through a first linear guide assembly, and the guiding direction of the first linear guide assembly is front and rear. . A locking structure for locking the telescopic rod 1b on the base 1a is also provided between the base 1a and the telescopic rod 1b. The locking structure includes a first screw nut assembly, the screw rod is rotationally connected to the base 1a, the screw nut is fixedly connected to the telescopic rod 1b, and a handwheel 1c is fixedly connected to the screw rod. According to the actual situation, the locking structure can adopt the following structure. The locking structure includes a locking bolt arranged at the bottom of t...

Embodiment 2

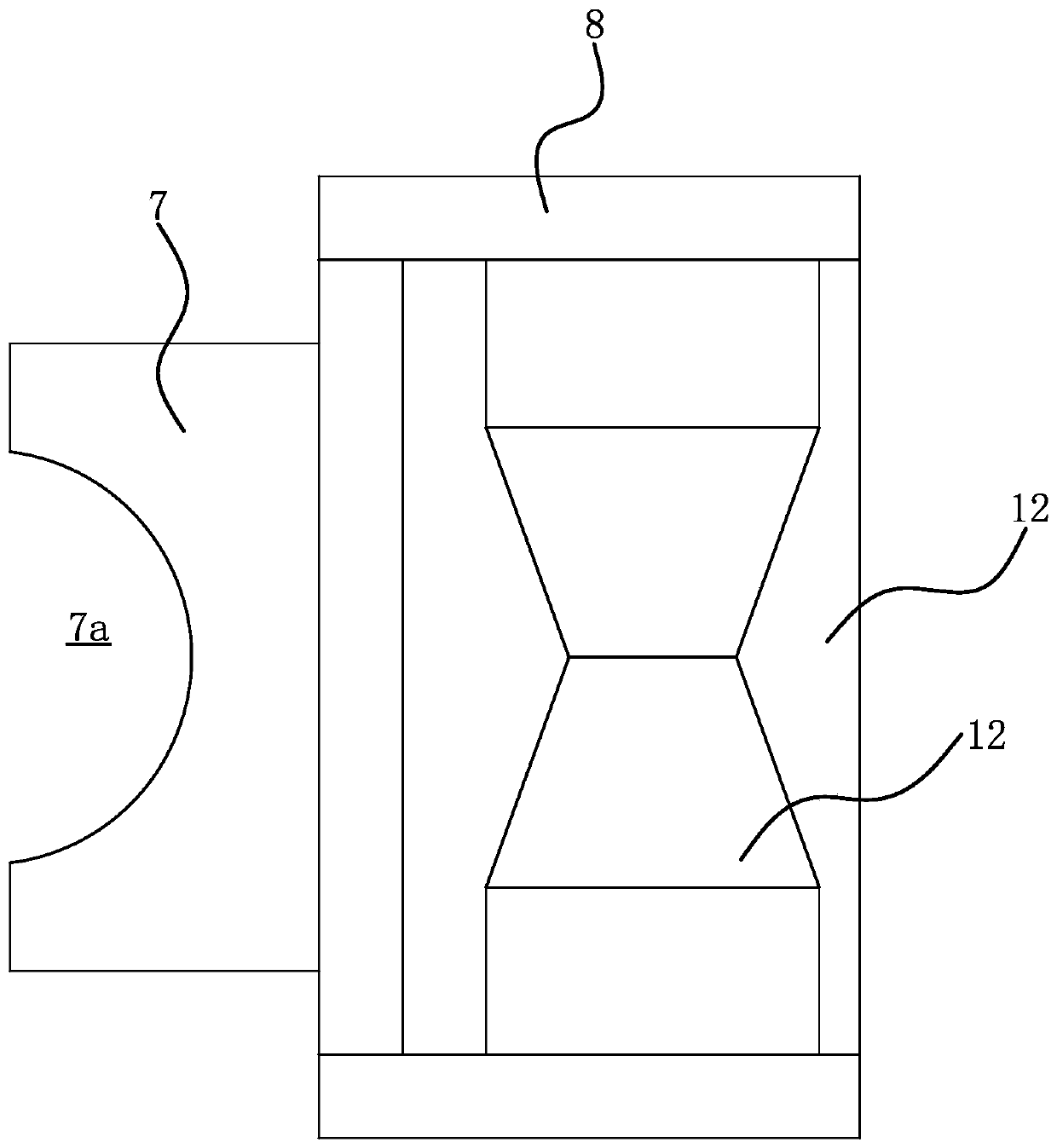

[0028] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be described repeatedly, only the differences will be described. The difference is that the telescopic rod 1b in the frame 1 is replaced by a fixed-length rod, That is, the height of the fixed seat 2 cannot be adjusted; the mobile structure between the connecting support 8 and the base 1a of the frame 1 can also make the support 8 move up and down, so the wire roller 12 is only connected with the support 8 through the rotating shaft; the mobile structure It includes the intermediate plate, the compression cylinder 9 and the fifth linear guide assembly connecting the bracket 8 and the intermediate plate, the fifth linear guide assembly is arranged horizontally, the cylinder body of the compression cylinder 9 is fixed on the intermediate plate, and the piston rod is connected with the bracket 8 ; The middle plate and the base 1a are connected t...

Embodiment 3

[0030] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be described redundantly, only the differences will be described. The difference lies in: the lower end of the telescopic rod 1b is directly fixedly connected to the base 1a .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com