Rotary kiln sintering state recognition method with artificial feedback regulation mechanism

A firing state and feedback adjustment technology, applied in character and pattern recognition, computer components, instruments, etc., can solve the problem that the simple feature space is not enough to fully represent the flame image, does not meet repeated scrutiny and comparison, and the robustness of the classifier Issues such as weak sex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only part of the embodiments of the present invention. Based on the embodiments of the present invention, other embodiments obtained by those skilled in the art without creative work all belong to the protection scope of this patent.

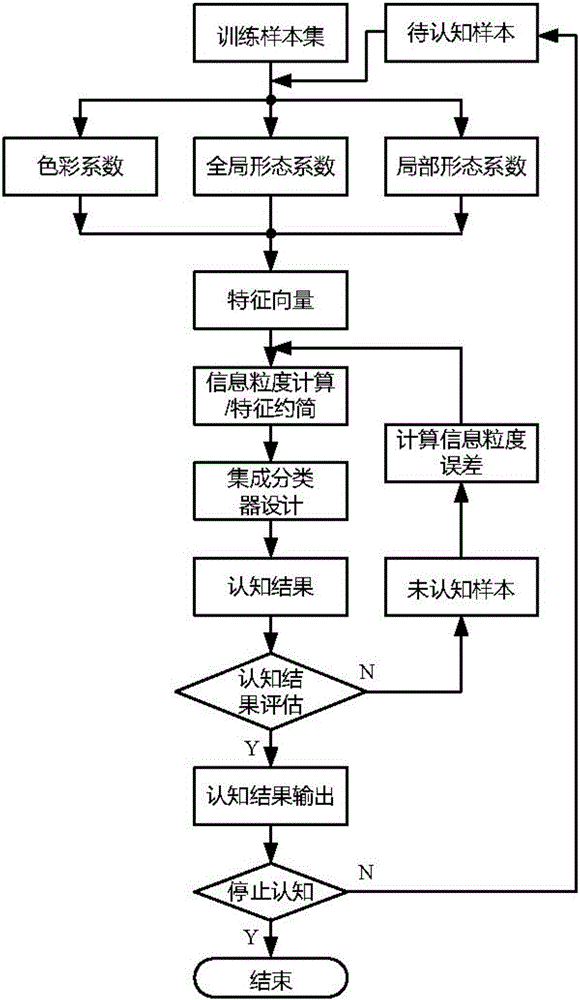

[0066] The embodiment of the present invention provides a rotary kiln firing state recognition method with an imitation feedback adjustment mechanism to solve the existing problems of incomplete cognitive feature space, fixed cognitive feature space, and classifier robustness. The problem of not being strong and the recognition rate is not high. Specifically, the steps are as follows:

[0067] Step 1. Shoot the rotary kiln in the running state to obtain the video of the firing state of the rotary kiln. From the video of the firing state of the rotary kiln,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com