A method and device for automatic testing of debug ports

An automatic test and port technology, applied in the field of data communication, can solve the problems of inability to perceive the connection of the card, the information of the main control card and the business card cannot be synchronized, and achieve the effect of clear presentation and improved inspection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical solution of the present invention clearer, the present invention will be described in further detail in conjunction with the accompanying drawings:

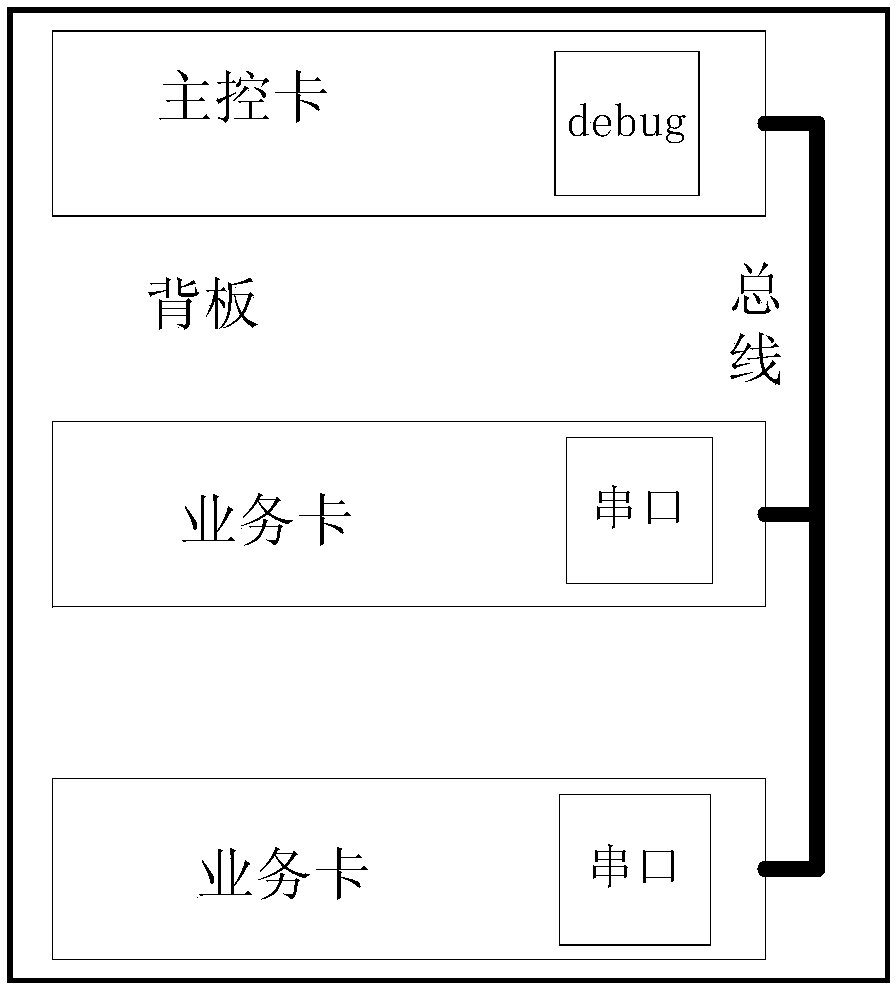

[0029] An embodiment of the present invention provides a method for automatic testing of a debug port. The method is applied to a rack-mounted device including a debug port to realize automatic testing of the entire debug hardware circuit on the rack-mounted device and improve the efficiency of production inspection.

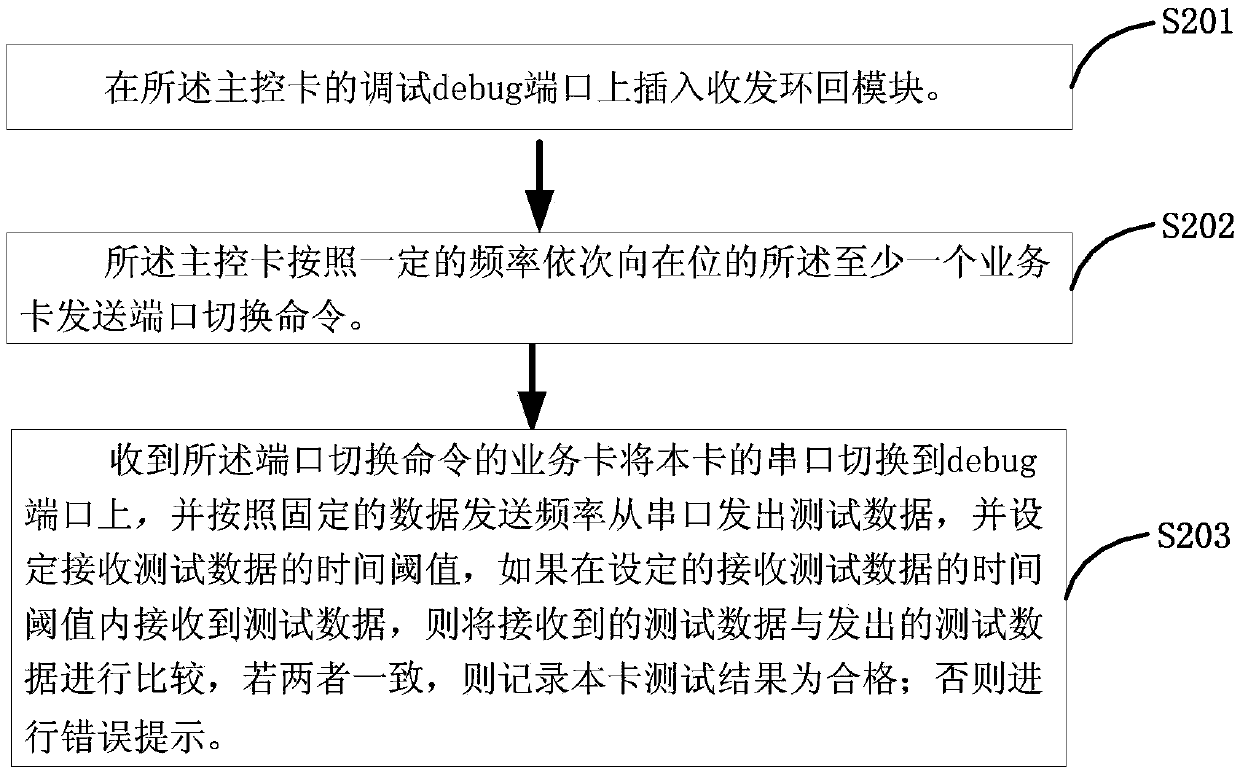

[0030] Such as figure 2 As shown, a method for automatically testing a debug port provided by an embodiment of the present invention is applied to a device including a main control card and at least one service card, and the method includes:

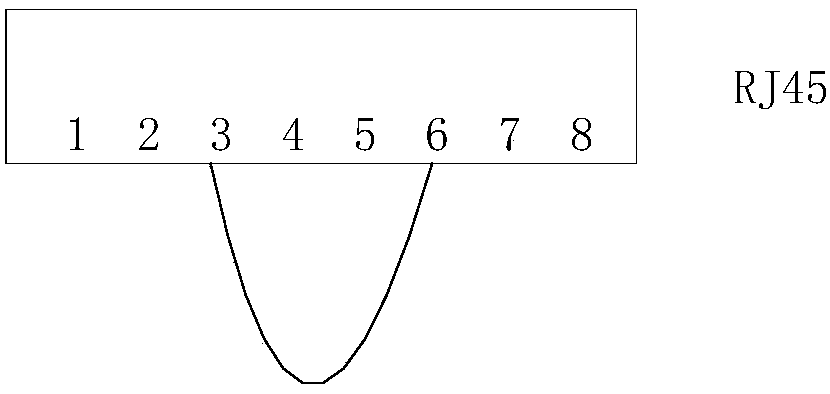

[0031] S201. Insert a transceiver loopback module into the debug port of the main control card; the transceiver loopback module is an RJ45 connector for connecting a receiving signal line and a sending signal line. Such as image 3 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com