Electronic cam control device and electronic cam curve generation method thereof

A technology of electronic cam and control device, applied in the direction of electrical program control, program control, general control system, etc., can solve the problems of machine damage, inconvenient use, etc., and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

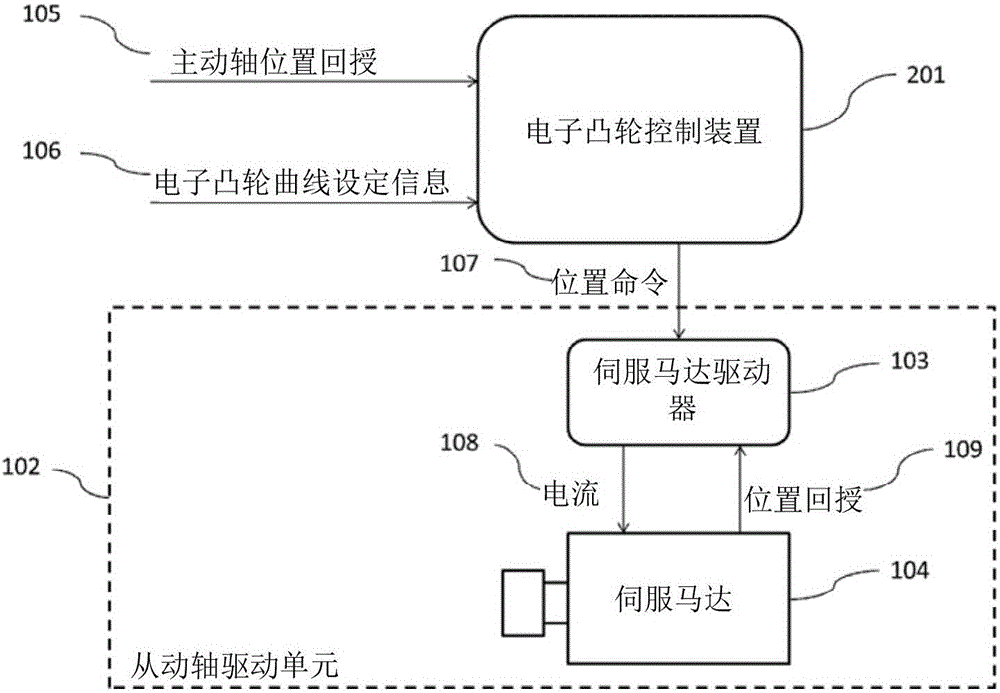

[0035] like figure 1 As shown, the electronic cam control device system, the electronic cam control device 201 receives the master shaft position feedback 105 and the electronic cam curve setting information 106, and after generating the electronic cam curve, sends the position command 107 to the driven shaft drive unit 102. The servo motor driver 103 , the servo motor driver 103 converts the position command 107 into a current 108 and outputs it to the servo motor 104 , and the servo motor 104 transmits the position feedback 109 to the servo motor driver 103 for action, so as to achieve the generation of the electronic cam control device 201 The electronic cam curve movement trajectory.

[0036] like figure 2As shown, the electronic cam control device 201 includes an information reading unit 202, which reads the specific point position and related parameters set by the user from the electronic cam curve setting file 210; an electronic cam curve generating unit 203, accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com