Hinge mechanism

A technology of hinge mechanism and fixed base, which is applied in the field of hinges, can solve the problems of broken hinges, reduced aesthetic effect, and no space, etc., and achieves the effects of convenient installation, simple and easy-to-understand adjustment operation, and small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

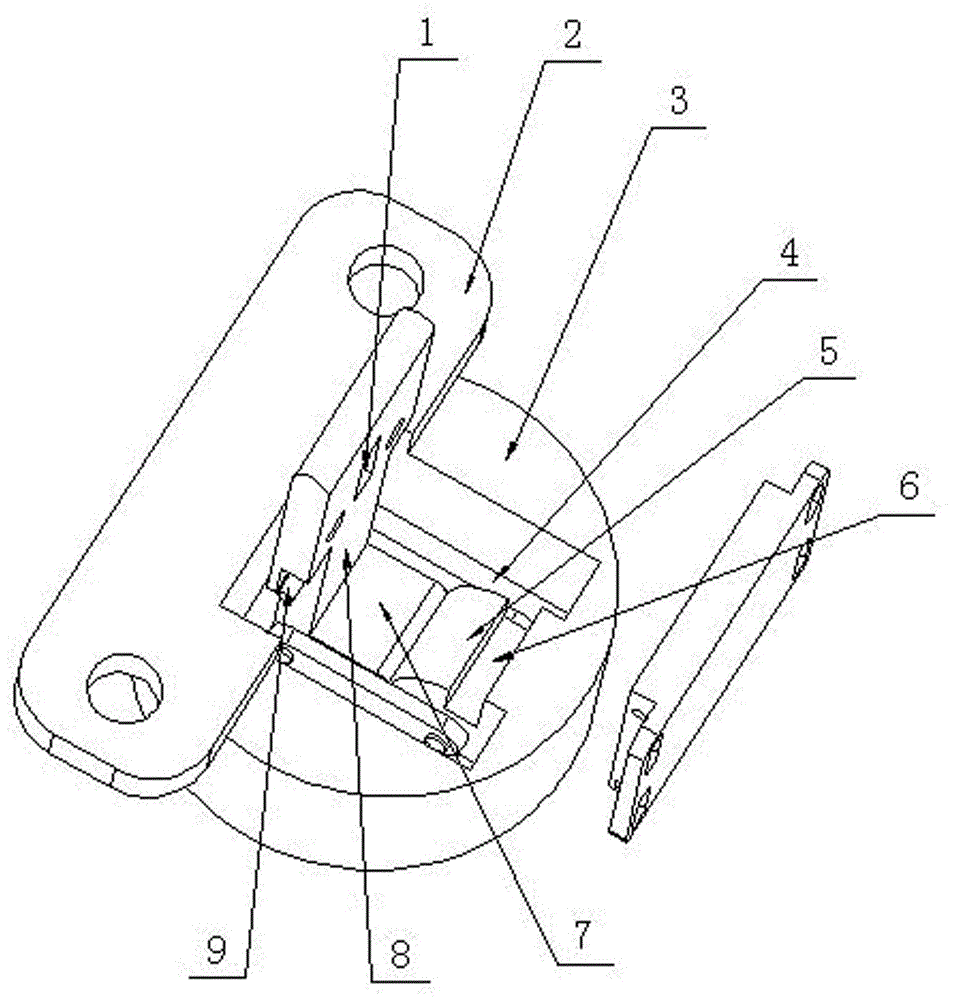

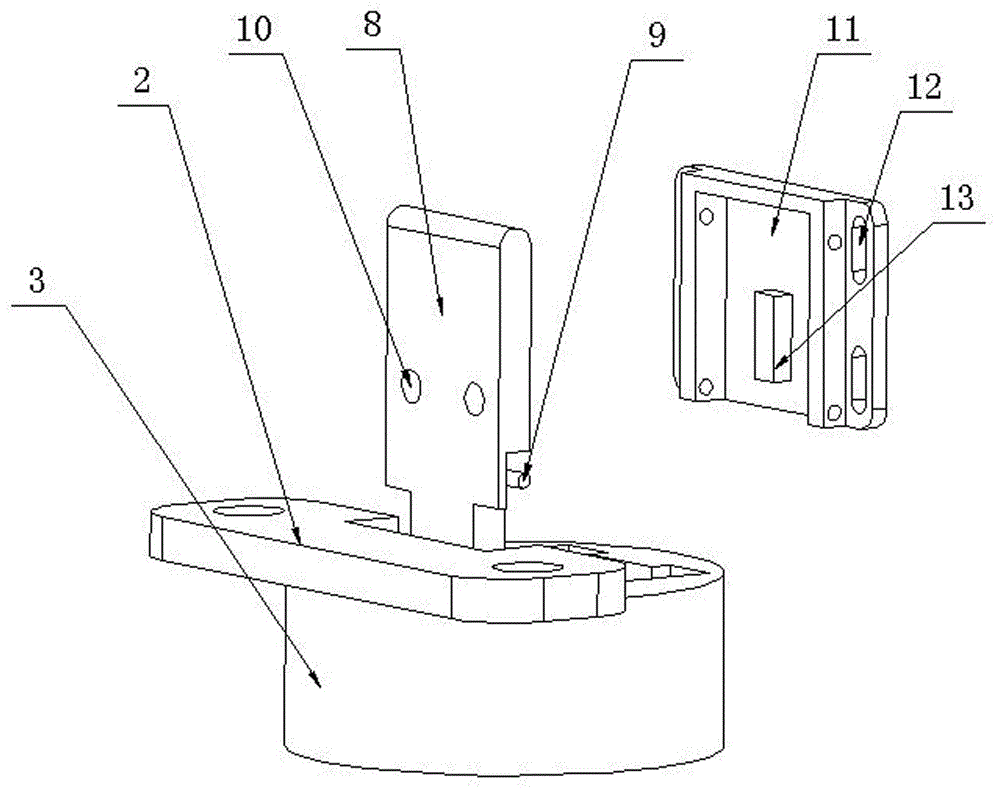

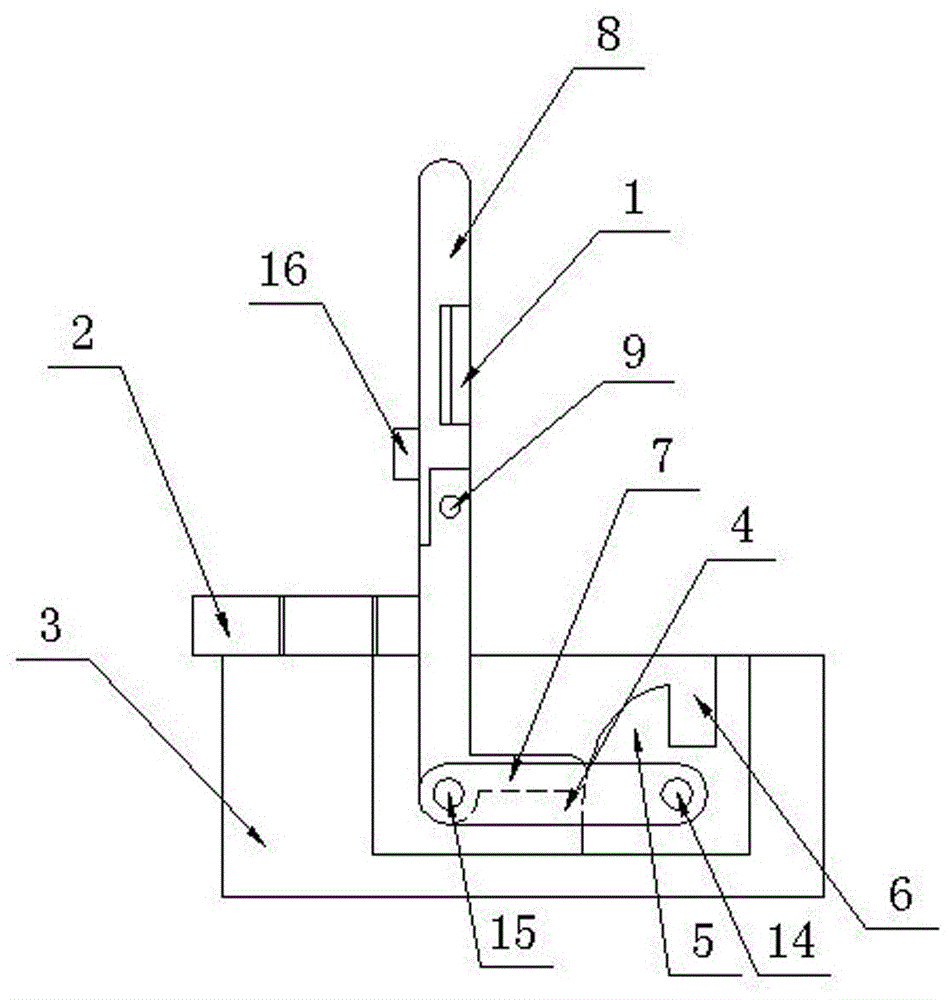

[0014] With reference to each figure, a hinge mechanism includes a fixed base 3 and a fixed wing 2, the fixed base 3 is connected to the fixed wing 2, the fixed base 3 is provided with horns 5, and the right side of the horns 5 is provided with a top tongue nest 6, A shaft B14 is arranged on the side wall of the horn 5, and the shaft B14 is connected with one end of the straight arm 4, and the other end of the straight arm 4 is connected with the shaft A15, and the shaft A15 is connected with the crank arm 8, and the crank arm 8 is provided with a top tongue 7, a top tongue 8 Contact with horn 5.

[0015] The crank arm 8 is provided with an adjustment nest 1, and the inside of the adjustment nest 1 is provided with an adjustment block 13, the adjustment block 13 is connected with the fixed seat 11, and the fixed seat 11 is provided with a positioning hole 12, and the shape of the positioning hole 12 is a waist hole .

[0016] The crank arm 8 is provided with an adjustment hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com