Calibration method of laser seam tracking sensor

A calibration method and sensor technology, applied in the field of sensor calibration, can solve problems such as difficulty in obtaining three-dimensional punctuation points, and achieve the effects of reducing the probability of human error, high precision, and simple experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0016] (1) Laser welding seam scanning tracking sensor system

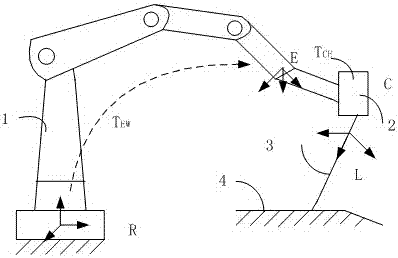

[0017] Such as figure 1 As shown, the laser scanning seam tracking sensor system is mainly composed of a laser seam tracking sensor 2 and a six-degree-of-freedom robot 1 . The laser seam tracking sensor is fixed at the end of the robot, and is controlled by the mechanical arm to detect the seam surface 4, using a straight-line structured light 3. The coordinate systems involved in this system are as follows. In the figure, {R} is the basic coordinate system fixedly connected to the robot base; {E} is the coordinate system of the degree of freedom at the end of the manipulator; {C} is the laser plane coordinate system. The equivalent optical path diagram is as follows figure 2 shown.

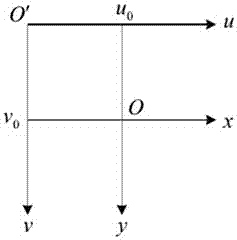

[0018] Camera coordinate system: camera focal length center point O c The coordinate system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com