Aluminum formwork early demolition beam connection device

A connection device and technology of aluminum formwork, which are applied to formwork/formwork/work frame, formwork processing, and on-site preparation of building components, etc., can solve the problems of automatic loosening, easy wear of pin holes, low tightness, etc. Achieve the effect of improving work efficiency, tight connection and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

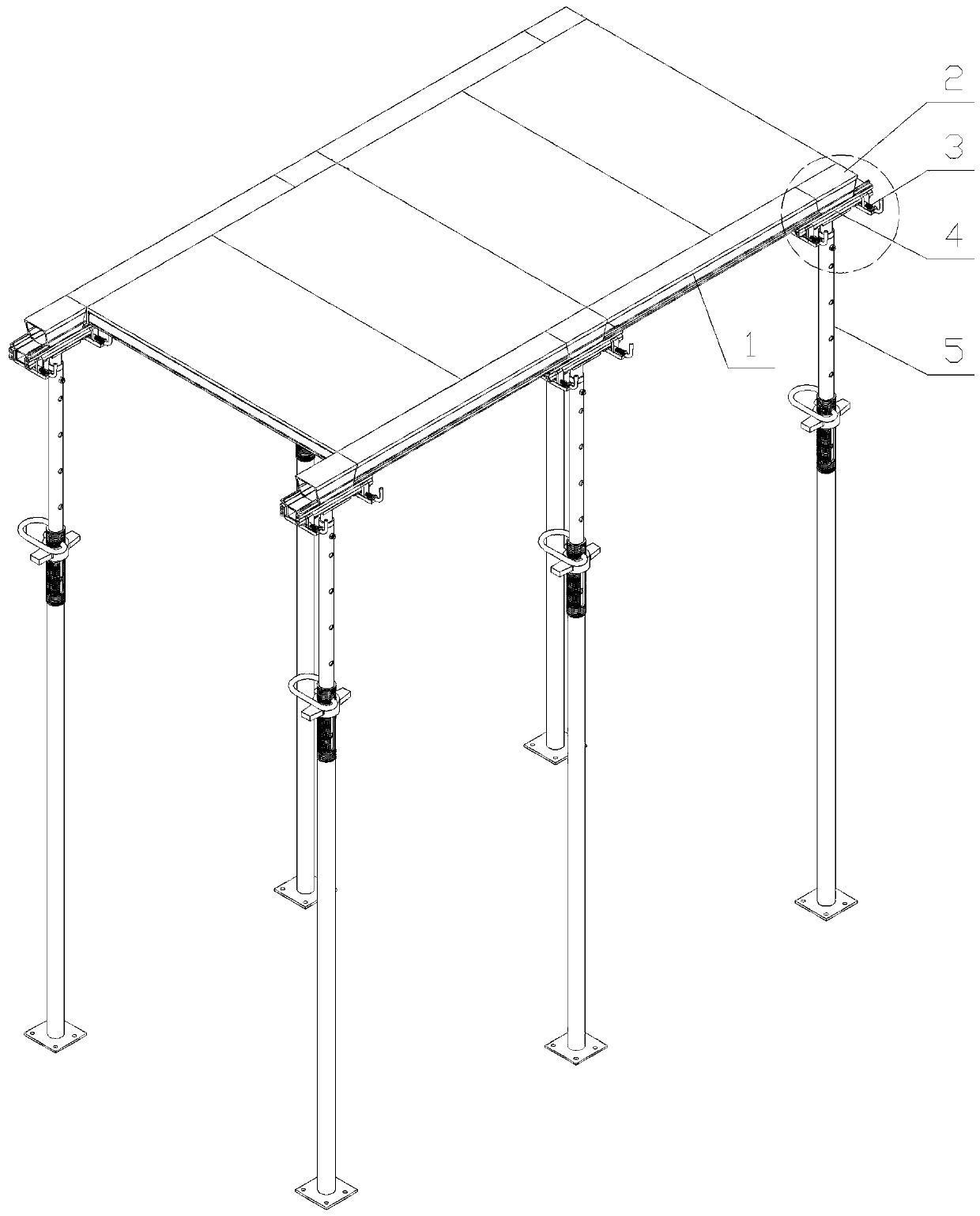

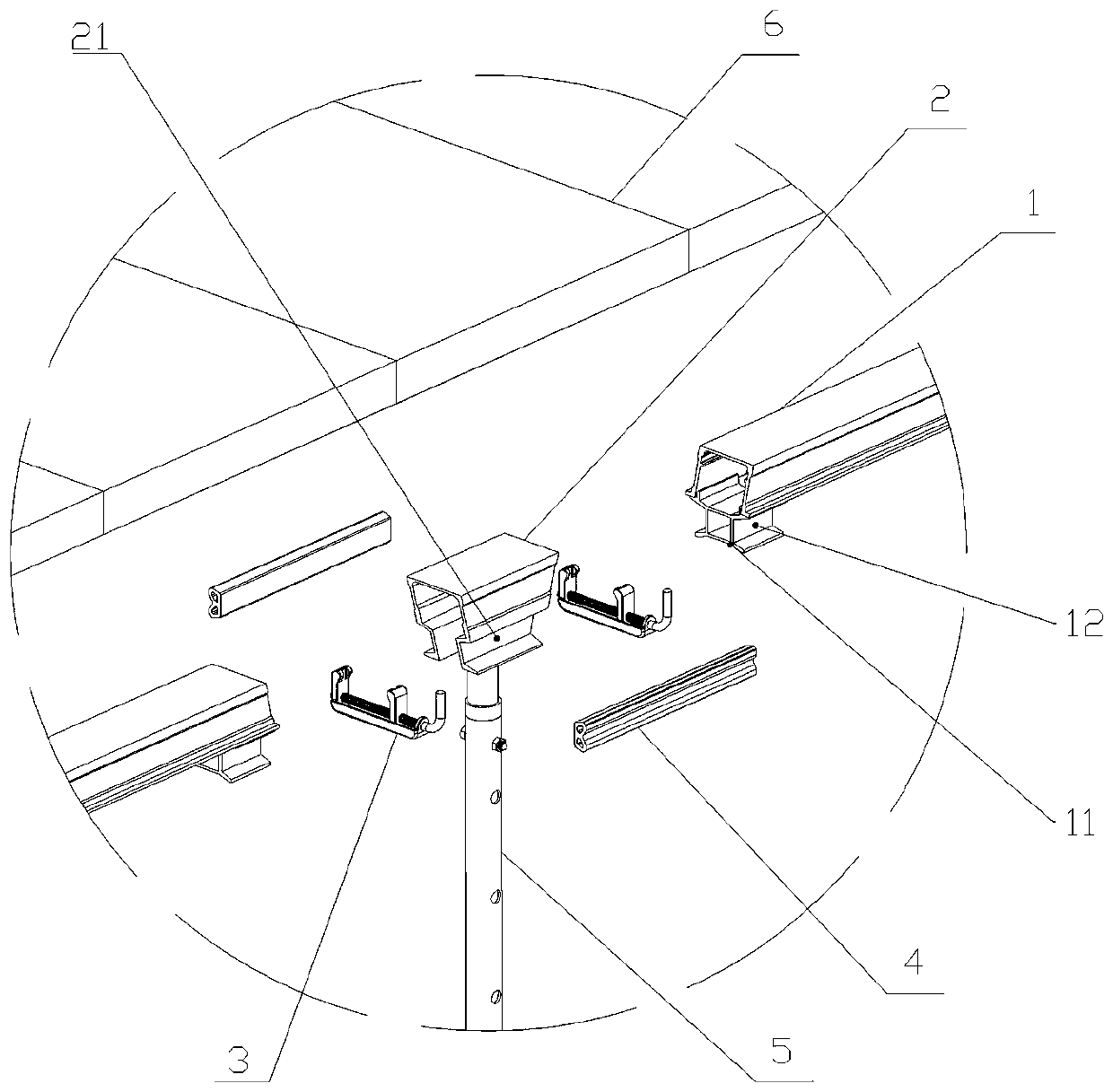

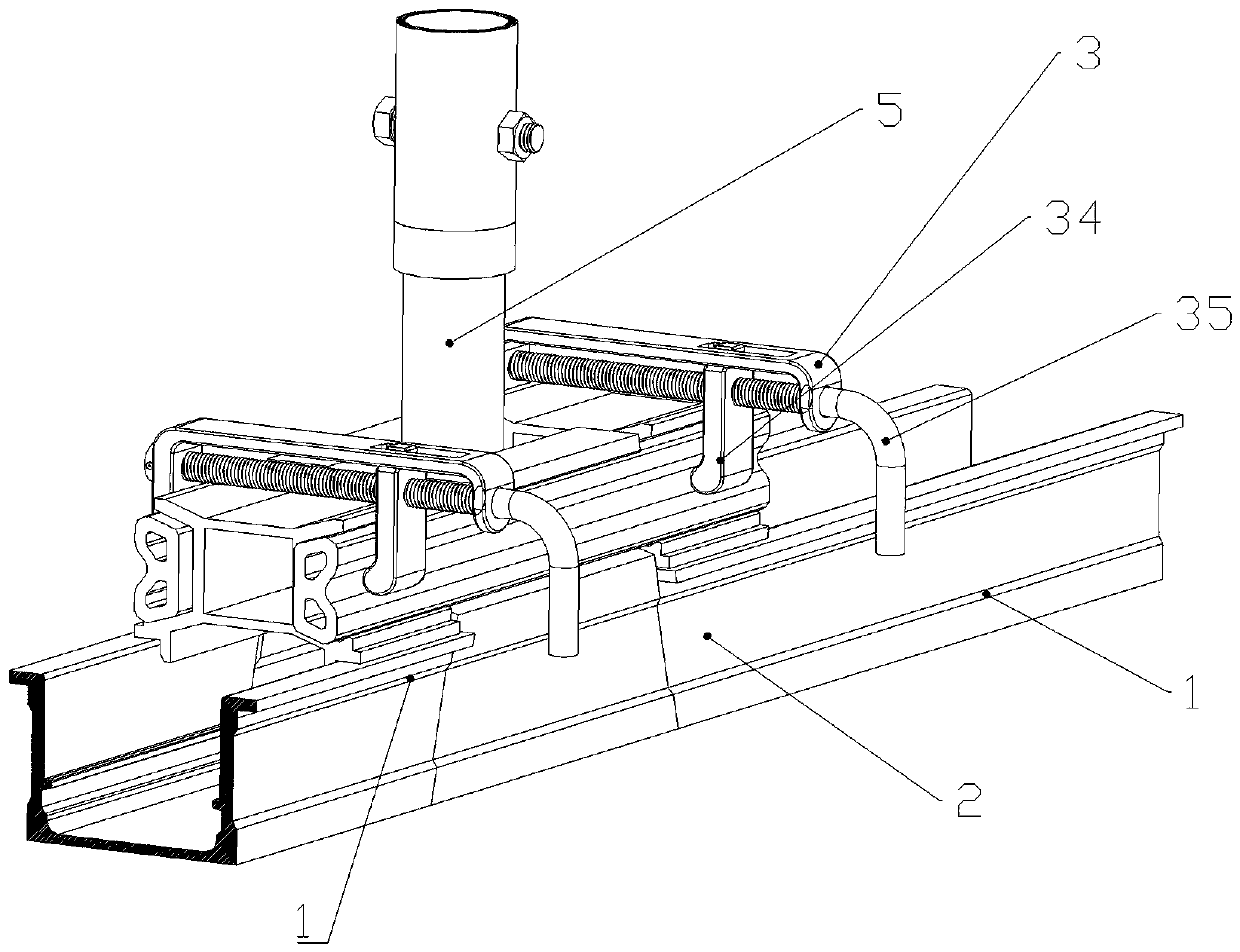

[0021] Such as Figure 1-Figure 5 As shown, the connecting device of the aluminum formwork early demolition beam 1 according to the present invention includes: a plurality of support columns 5 , an early demolition beam 1 mechanism, and a formwork assembly 6 . The mechanism of the early removal beam 1 includes a support head 2, an early removal beam 1, two support rods 4, and two locking devices. The early removal beam 1 is located at both ends of the support head 2, and positioning grooves 21 are provided on both sides of the bottom of the support head 2. The two sides of the bottom of one end of the early demolition beam 1 adjacent to the support head 2 are respectively provided with a positioning block 11, and the positioning block 11 is provided with a card slot 12 corresponding to the positioning groove 21 on both sides of the bottom of the support head 2, and the two supporting rods 4 are respectively One piece is clamped in the positioning grooves 21 on both sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com