A battery quantitative spraying device

A technology of spraying device and battery, applied in the direction of spraying device, etc., can solve the problems of affecting the next process and battery quality, difficult to evenly coat the sealant, and the equipment occupies a large space, so as to achieve the smooth movement of the nozzle and the use of the sealant. High rate and good spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

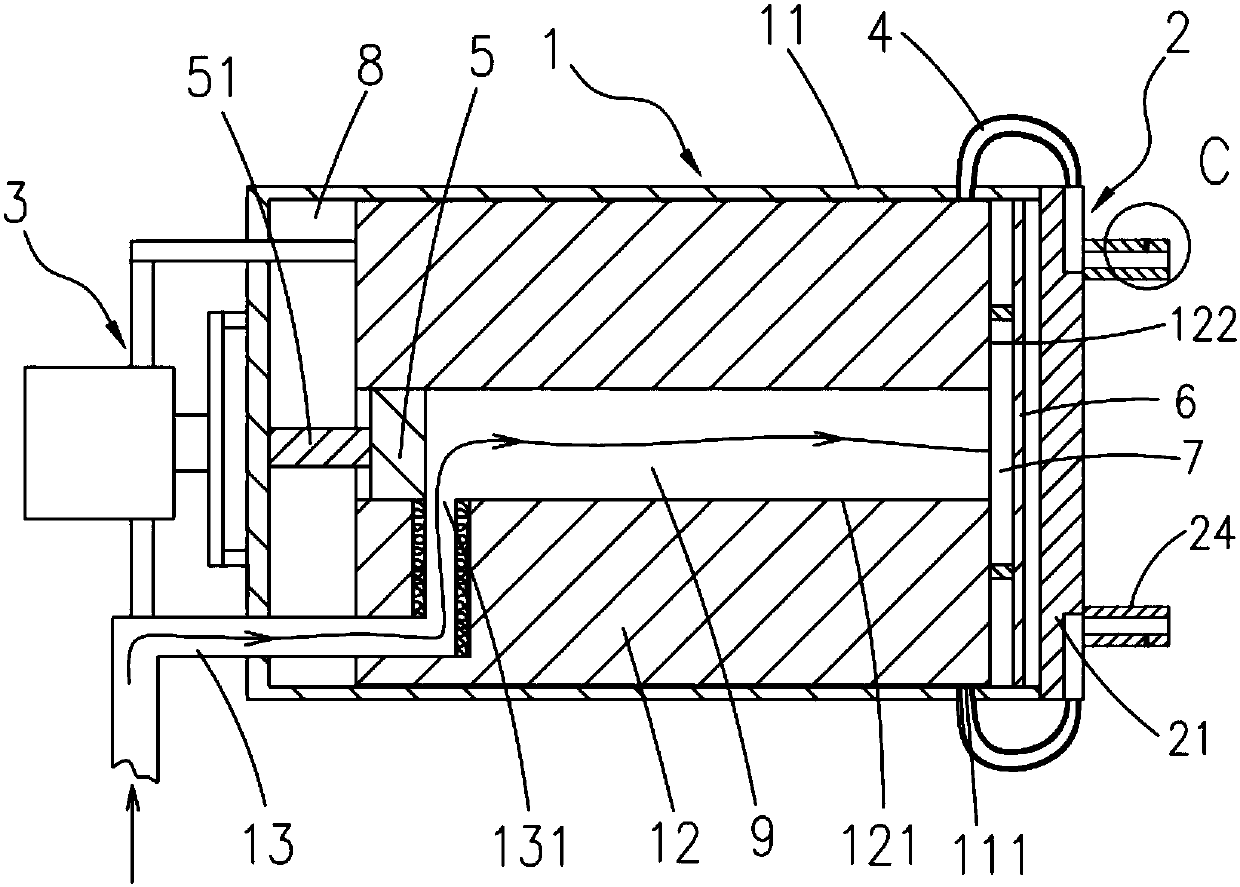

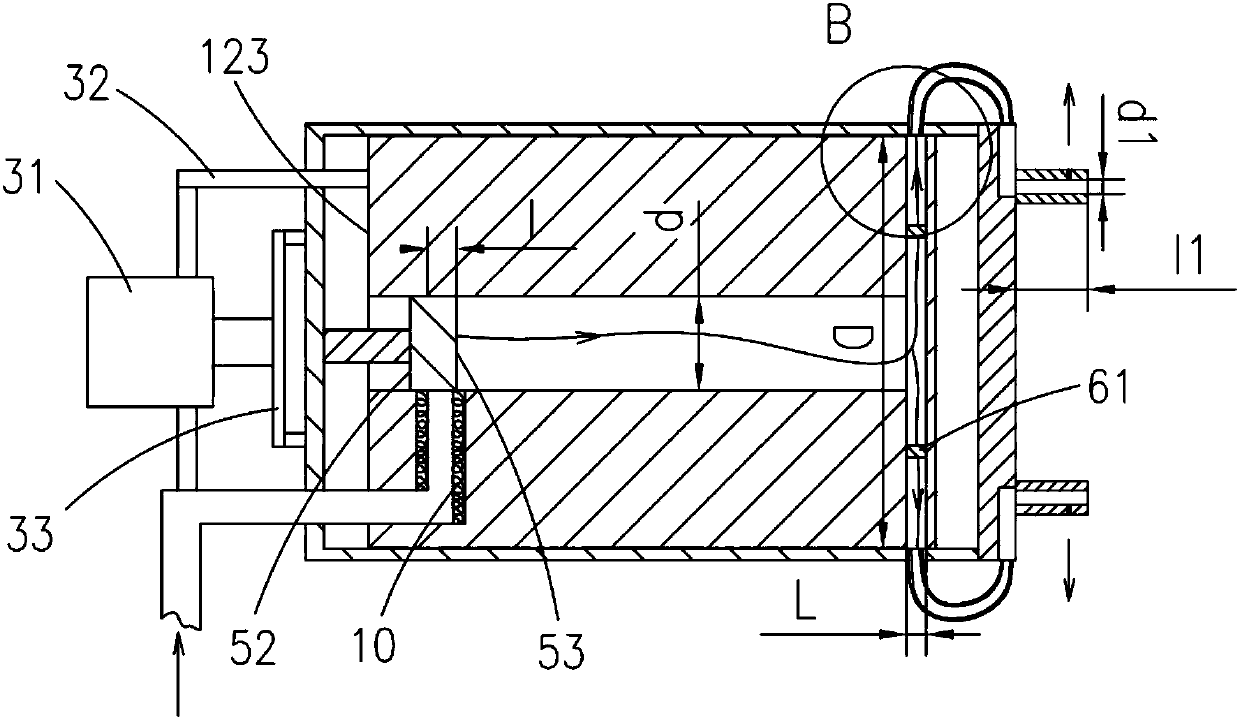

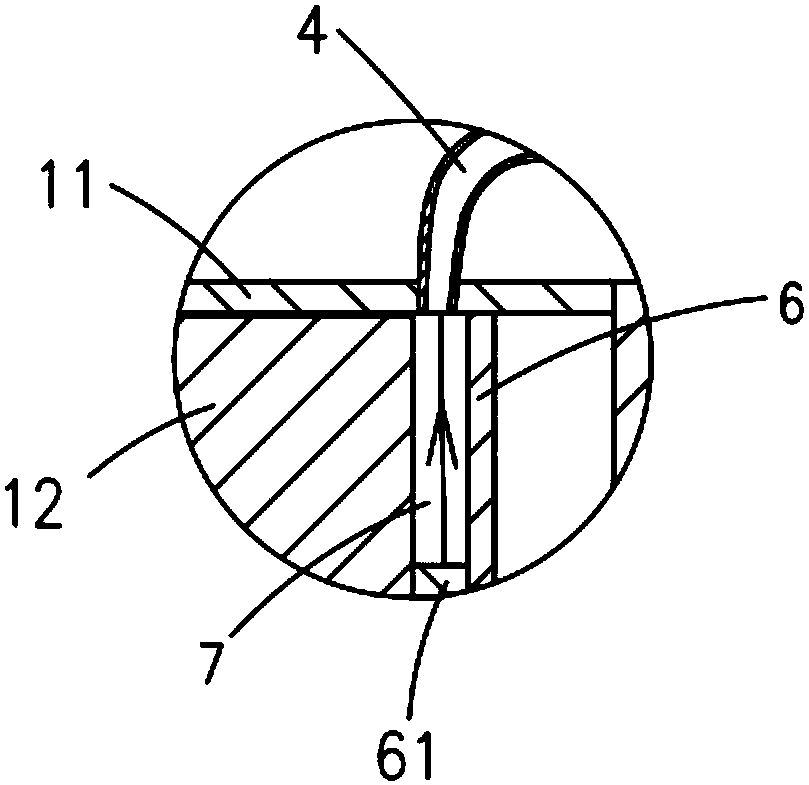

[0029] Such as figure 1 As shown, the present invention provides a battery quantitative spraying device, including a flow regulating mechanism 1 for automatically adjusting the flow of sealing agent, a rotary spraying mechanism 2 and a transmission mechanism 3, and the rotary spraying mechanism 2 is installed on the front end of the flow regulating mechanism 1 The transmission mechanism 3 is installed on the rear end of the flow regulating mechanism 1, and the transmission mechanism 3 drives the rotary spraying mechanism 2 to move left and right through the flow regulating mechanism 1; the flow regulating mechanism 1 includes an outer cover 11. The agent cylinder 12 and the agent tube 13 placed in the cavity of the outer cover 11, the inside of the agent cylinder 12 is provided with a through hole 121 along its axial direction, and a piston 5 is arranged for airtight sliding in the through hole 121, and the piston 5 passes through the connecting rod 51 It is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com