Aliphatic polycarbonate having long chain branch and aromatic polyester copolymer thereof

一种芳香族聚酯、聚碳酸酯的技术,应用在具有长支链的脂肪族聚碳酸酯及其芳香族共聚酯领域,能够解决慢增加、最终聚合物分子量限制等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

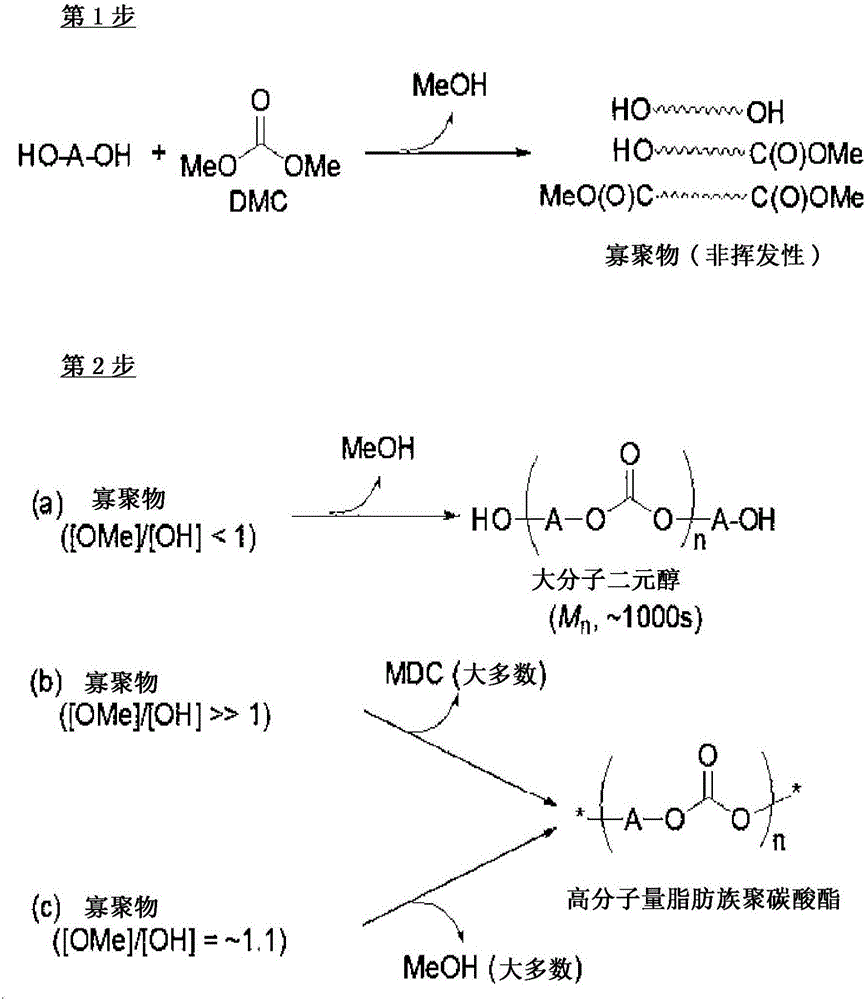

Method used

Image

Examples

Embodiment 1~11

[0045] Embodiment 1~11. have the preparation (condensation reaction of the compound of formula 1a and the compound of 2a~2d and DMC and dimethyl terephthalate) with long-chain branched aliphatic polycarbonate-aromatic polyester copolymer

[0046] Step 1: 1,4-butanediol (Formula 1a, 10.0 g, 110 mmol) and each of the compounds of Formulas 2a~2d were placed in a three-necked flask and NaOH (0.222 mmol, 0.2 mol%) was added thereto. As shown in Table 1, the compounds of formulas 2a-2d are used in an amount of 0.2 mol%-0.7 mol%. After further addition of toluene (10 ml), a mechanical stirrer was attached to one neck of the bottle, a manifold with vacuum and nitrogen lines attached was connected to the other neck of the bottle, and a Dean- A Stark cold trap was attached to the remaining neck of the bottle. After the reaction vial was immersed in a constant temperature bath, moisture in the mixture was removed by azeotropic distillation with reflux with toluene. After 2 hours, the m...

Embodiment 12~20

[0053] Embodiment 12~20. have the preparation (condensation reaction of the compound of formula 1a and the compound of 2a~2d and DMC) of long-chain branched aliphatic polycarbonate

[0054] Step 1: Repeat the process of Examples 1-11 until moisture is removed from the mixture. Thereafter, the addition of dimethyl terephthalate was omitted and instead the amount of DMC was increased to 15.7 g (174 mmol). After the reaction, the three-necked flask was immersed in a 120° C. constant temperature bath, and the reaction was carried out for 1 hour while distilling off formed methanol and a part of DMC under normal pressure. After heating to 190°C, the reaction was continued while removing volatiles under reduced pressure at 570 mmHg for 0.5 hour, 380 mmHg for 1 hour, and 190 mmHg for 2 hours. Thereafter, the reaction was allowed to proceed for an additional 2 hours while removing volatiles under high vacuum (maintained using a vacuum pump) of 0.3 mmHg. The experimental results are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com