Automatic numbering device and method for temperature sensors

A temperature sensor and automatic numbering technology, applied in the field of building construction, can solve the problems of low sensitivity of temperature sensor, long time consumption, omission or error of numbering, etc., to improve the work effect and overcome the effect of long time consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

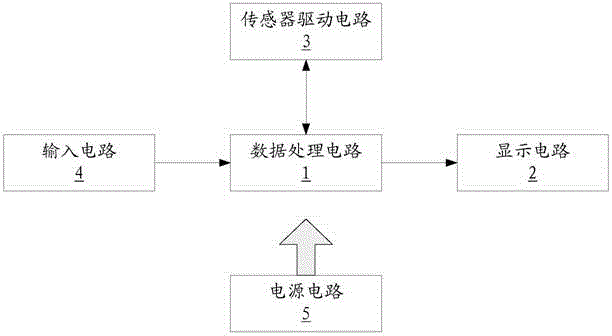

[0034] Please refer to Figure 1-6 , the first embodiment provides an automatic numbering device for temperature sensors, including

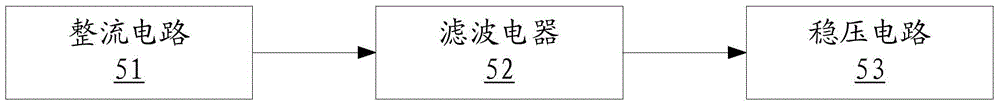

[0035] The power supply circuit 5 provides power supply; the power supply circuit 5 includes a rectification circuit 51 , a filter circuit 52 and a voltage stabilization circuit 53 .

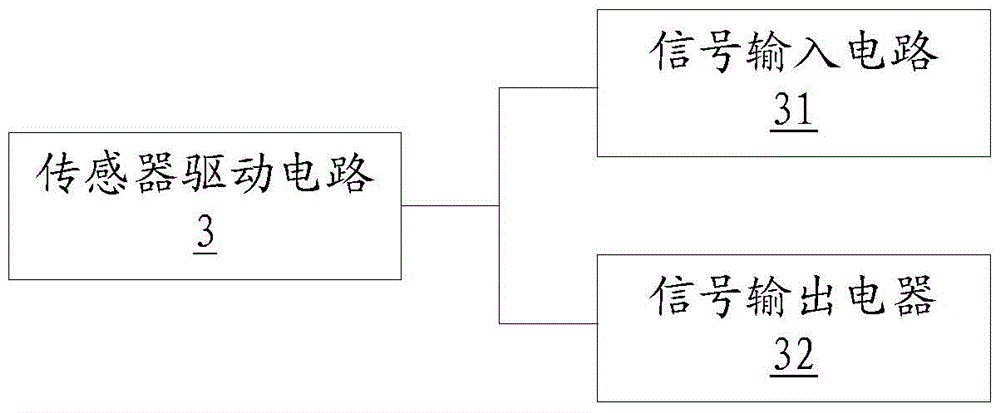

[0036]The sensor drive circuit 3 is used to drive all the temperature sensors of the temperature measurement axis; the sensor drive circuit 3 includes a signal input circuit 31 and a signal output circuit 32; wherein the signal output circuit 32 is used to output the control signal of the data processing circuit 1 To the temperature sensor; wherein the signal input circuit 31 is used to send the temperature signal collected by the temperature sensor to the data processing circuit 1 .

[0037] The display circuit 2 is used to display the current temperature information of the temperature sensor; the display circuit 2 includes a display screen 21, which is used to ...

Embodiment 2

[0041] Please refer to Figure 7 , the second embodiment provides a method for automatic numbering of temperature sensors, comprising the following steps:

[0042] First, integrate the temperature function measured by the temperature sensor at the nth position of the temperature measurement axis for the kth time to obtain the integral function Wherein, k and n are natural numbers greater than 0;

[0043] Second, the integral function of the current temperature of the temperature sensor at the nth position Integral function with last temperature The maximum function of the absolute value of the difference in temperature Compare with the set temperature difference threshold Tc;

[0044] Again, when the maximum function When the temperature value is greater than the temperature difference threshold Tc, the temperature sensor at the nth position is automatically numbered;

[0045] Finally, repeat the above steps until the automatic numbering of all temperature sensors o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com