Defrosting control method for variable-capacity compressor system

A variable-capacity compressor and control method technology, applied in the field of air conditioners, can solve problems such as affecting user comfort and a large reduction in indoor ambient temperature, and achieve the effects of increasing the amount of refrigerant circulation, avoiding a significant reduction, and improving the defrosting speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

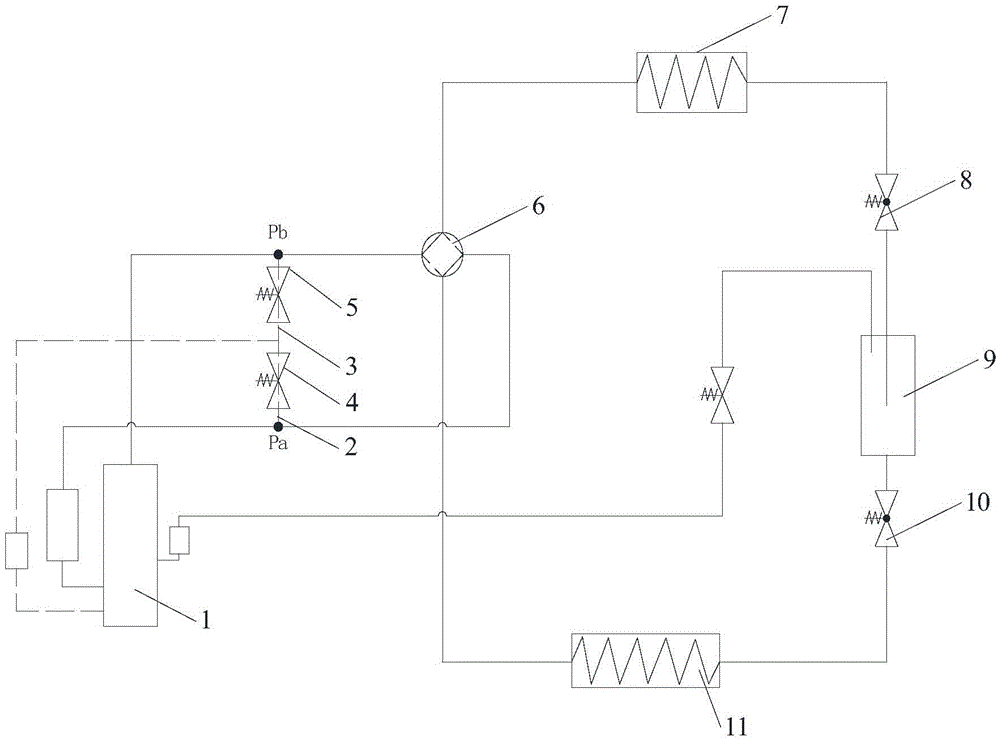

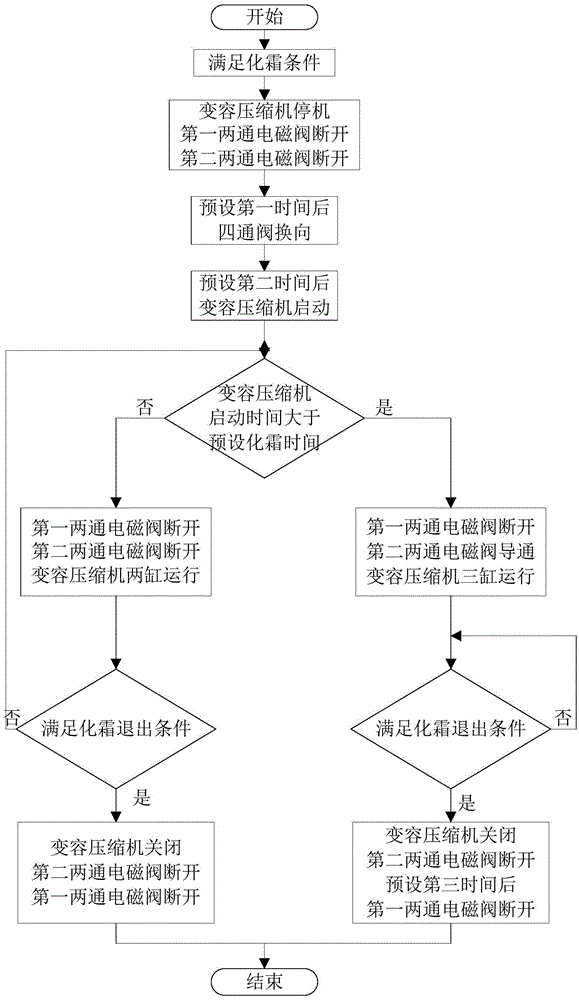

[0021] Combine Figure 1 to 3 As shown, in the present invention, the variable-capacity compressor system includes a variable-capacity compressor 1, a four-way valve 6, and a first control that is selectively connected to the variable-capacity control port of the variable-capacity compressor 1 through a variable-capacity switching valve. The tube 2 and the second control tube 3 can selectively introduce high pressure or low pressure through the first control tube 2 and the second control tube 3, thereby realizing the change of the number of working cylinders of the variable capacity compressor 1, that is, realizing the variable capacity. It should be noted that in the present invention, high pressure and low pressure are relative values, that is, the high pressure is greater than the low pressure, and both are between the suction pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com