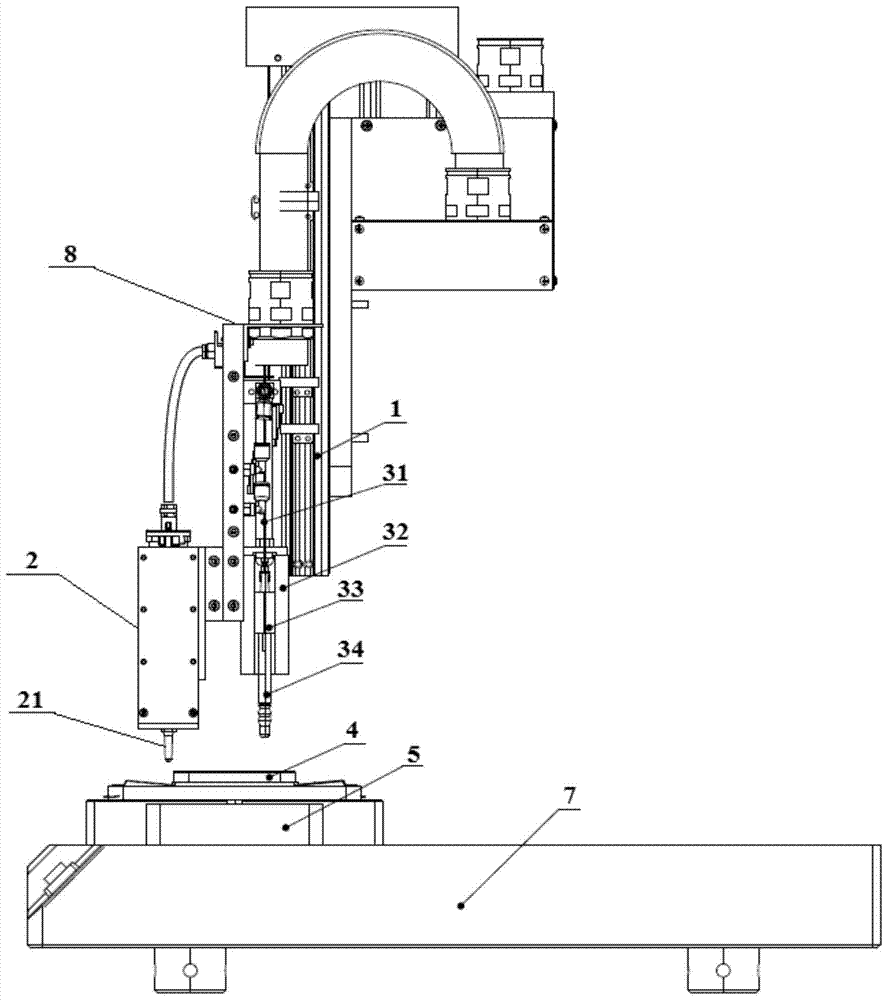

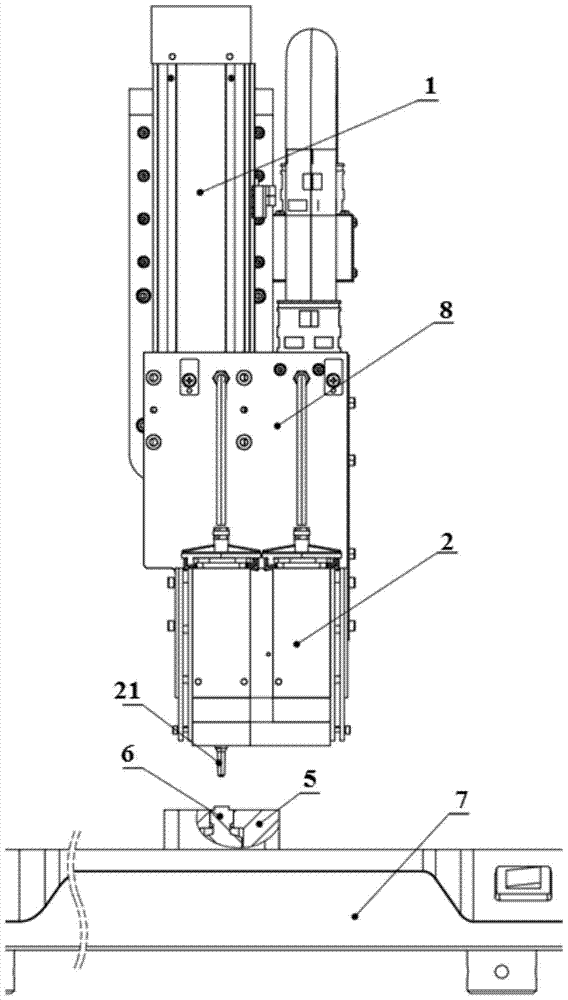

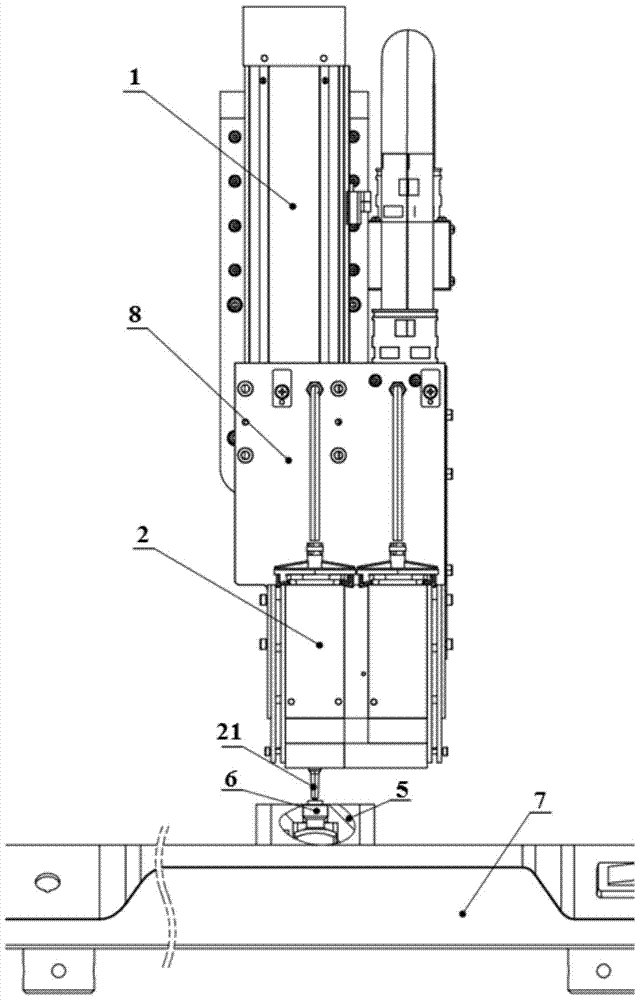

Bioprinter and its calibration method

A bioprinter and printing material technology, applied in medical science, prosthesis, etc., can solve the problems of complicated operation, low precision, poor reliability, etc., and achieve the effect of improving measurement accuracy, reducing labor intensity, and simplifying operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0058] As an embodiment of the bioprinter of the present invention, the first detection device can control the control device to start measuring the change in the length of the injection device when the bottom end of the injection device moves to the first position along the Z-axis direction, and the first signal It is a signal for controlling the control device to start measuring the variation of the length of the injection device, the control device can start to measure the variation of the length of the injection device after receiving the first signal and can adjust the injection device according to the variation of the length of the injection device and / or, the second detection device is used to control the control device to start measuring the height variation of the initial adhesion surface of the printing material, and the second signal is used to control the control device to start measuring the initial adhesion of the printing material The signal of the change amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com