Battery shell breaking disassembling apparatus

A battery and shell breaking technology, which is applied in battery recycling, solid waste removal, recycling technology, etc., can solve the problems of long process flow, slow disassembly speed, and incomplete separation, so as to reduce wear and prevent jamming , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

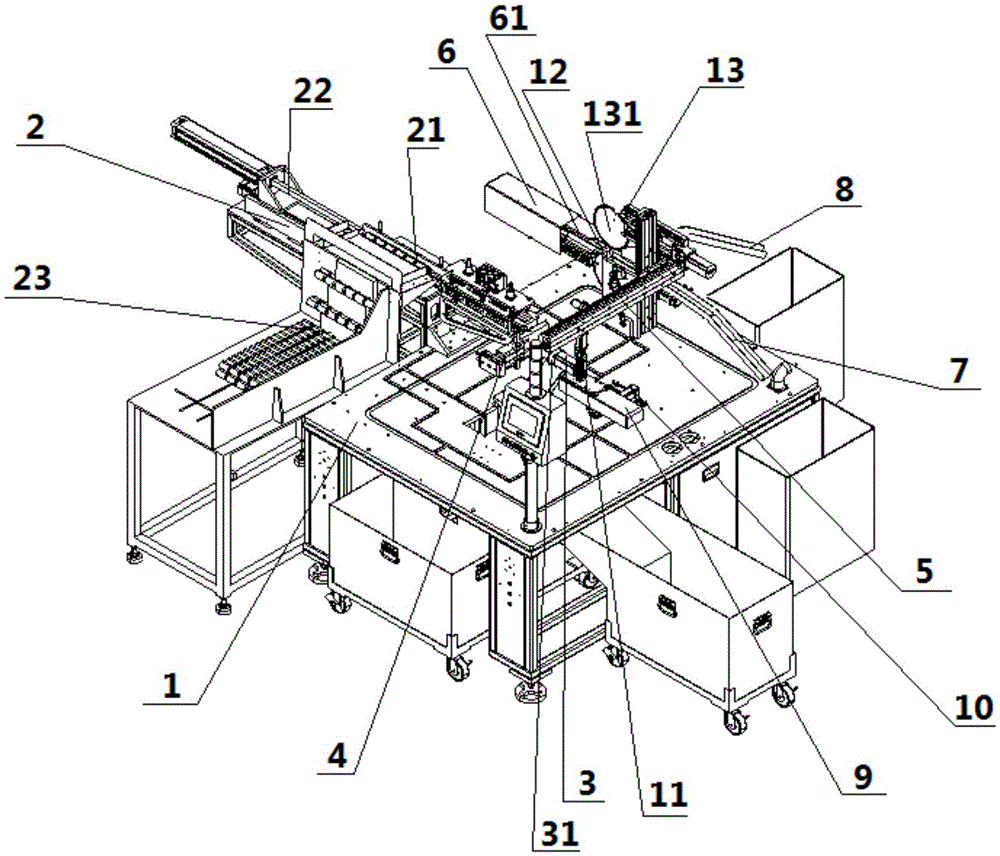

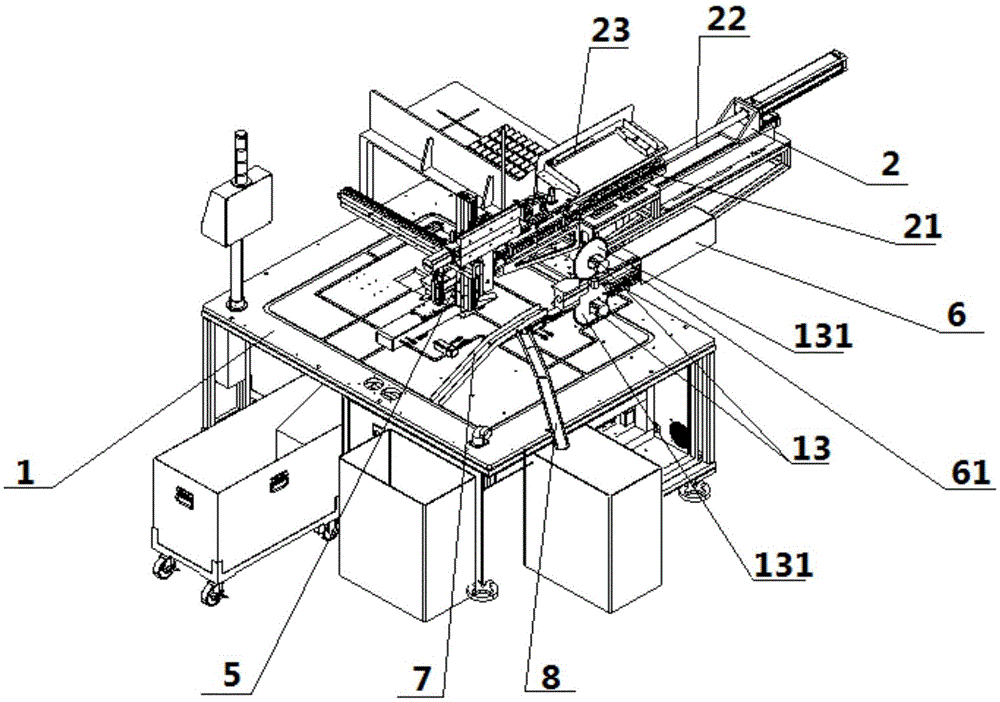

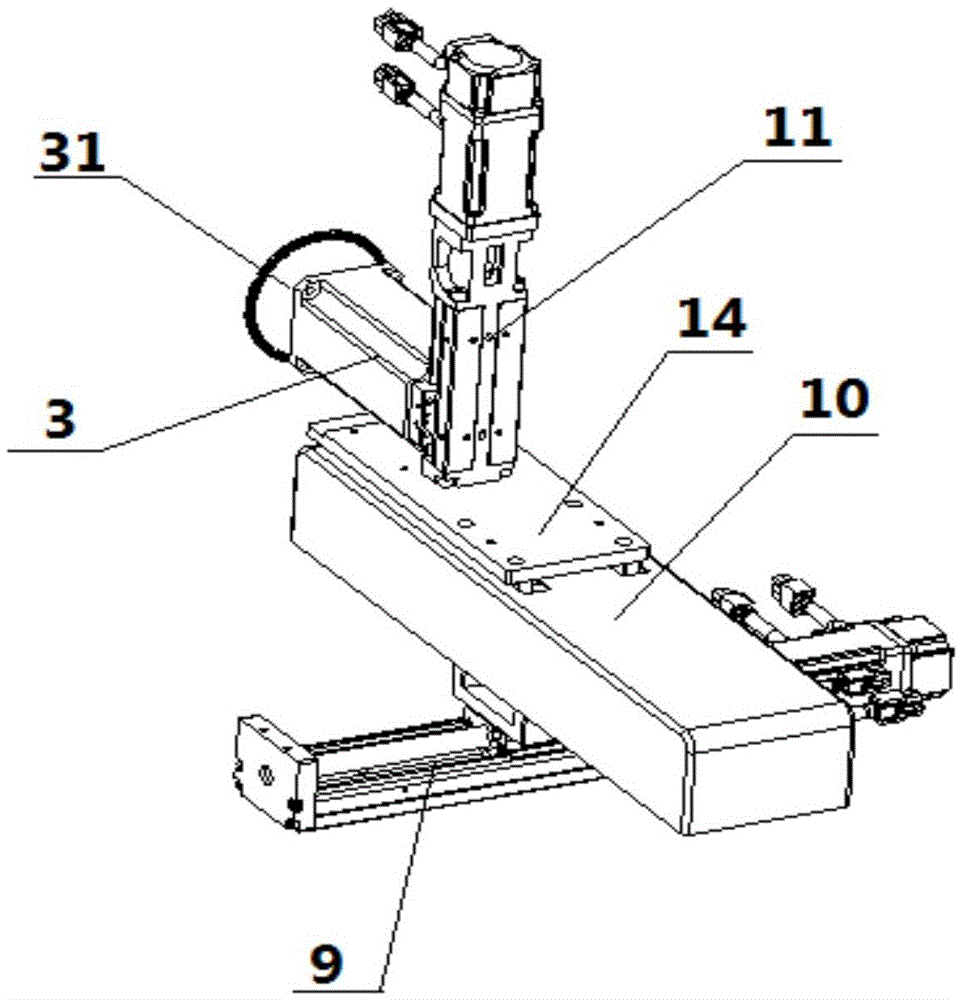

[0017] A battery breaking and dismantling equipment, such as figure 1 , figure 2 As shown, it includes a feeding device 2 installed on a frame 1, a longitudinal circular cutting device 3, a rotatable and telescopic clamping device 4, a separating device 5, a core pushing device 6, a cell discharge chute 7 and a shell discharge Groove 8, feeding device 2 comprises feed trough 21, push rod 22 and feed hopper 23, and push rod 22 is arranged in the front of feed trough 21, and the outlet of feed hopper 23 is arranged on feed trough 21 above; if image 3 As shown, the longitudinal annular cutting device 3 is installed on the guide rail of the Z-axis motion mechanism 11 among the mutually perpendicular X-axis motion mechanism 9, Y-axis motion mechanism 10, and Z-axis motion mechanism 11, and the Y-axis motion mechanism 10 is installed on the X-axis On the guide rail of motion mechanism 9, Z-axis motion mechanism 11 is installed on the slide plate 14 that is arranged on the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com