Circuit breaker and transmission device thereof

A technology of transmission device and circuit breaker, applied in the direction of protection switch operation/release mechanism, etc., can solve the problems of wear and tear of lateral tie rods, and achieve the effects of small friction force, small wear, and improve transmission efficiency and movement reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

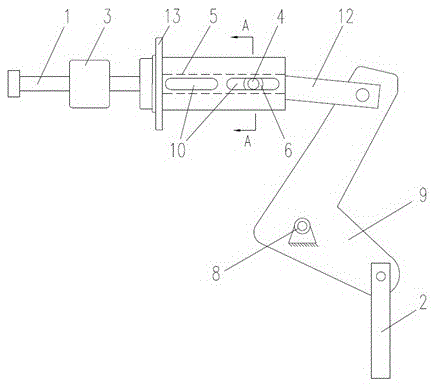

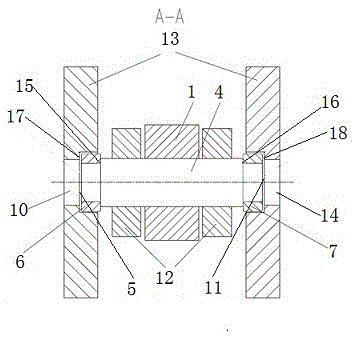

[0020] The embodiment of circuit breaker in the present invention is such as figure 1 with 2 shown. The circuit breaker includes a transmission device. The transmission device includes a transverse tie rod 1 connected to the movable contact and a crank arm 9 that is connected to the transverse tie rod 1 through a connecting plate 12 to drive the rotation axis of the transverse tie rod 1 to move left and right along the front and rear directions. The connecting plate One end of 12 is hingedly connected with crank arm 9, and the other end of connecting plate 12 is hingedly connected with transverse tie rod 1. The transmission device also includes hinge pin shaft guide 13, and hinge pin shaft guide 13 is provided with hinge pin shaft in left and right direction. The hinge pin shaft guide structure with upper guide movement matching. The crank arm 9 is hinged to the fixed hinge point 8 on the frame of the circuit breaker. The transmission device also includes a transmission rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com