membrane switch

A membrane switch, conductive layer technology, applied in electrical switches, contact with a separate bridge contact, emergency contact form, etc., can solve the problems of complex membrane switch production process, short circuit of circuit boards, poor contact, etc., to reduce the circuit Bad risk, improved yield, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

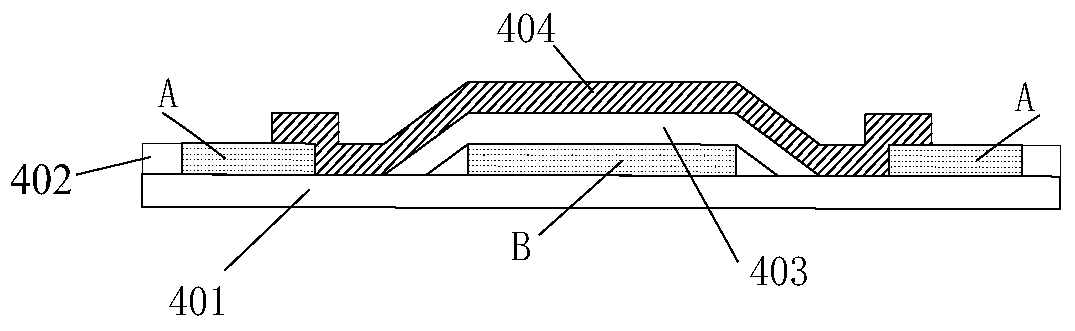

[0013] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

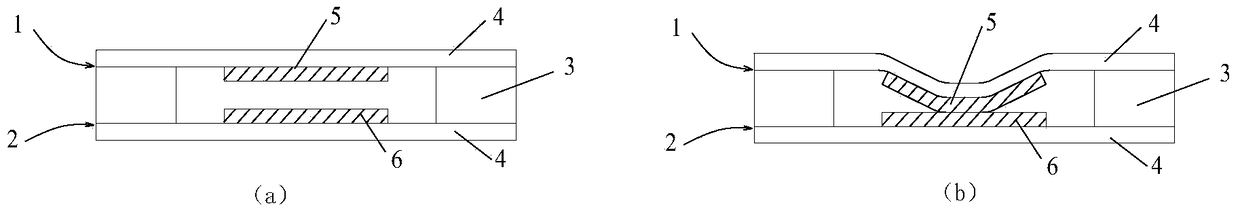

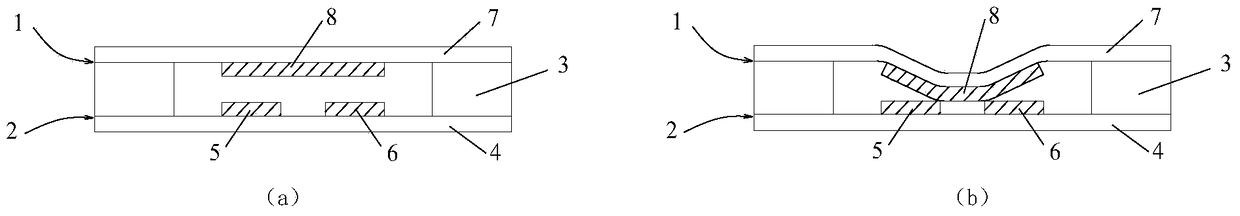

[0014] Such as figure 1 As shown, the traditional membrane switch includes an upper conductive layer 1, a lower conductive layer 2 and an insulating layer 3 between them. The upper conductive layer 1 and the lower conductive layer 2 have the same structure, and both the upper and lower conductive layers are provided with conductive lines. Layer 4 and the trigger part located on the conductive circuit layer 4, wherein the trigger part of the upper conductive layer 1 is connected to the positive electrode as the positive electrode trigger part 5, and the trigger part of the lower conductive layer 2 is connected to the negative electrode as the negative electrode trigger part 6. When not conducting, the positive trigger part 5 is separated from the negative trigger part 6, and the membrane switch is pressed, the upper conductive layer 1 is deform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com