Copper strip tinning pressing roller device

A technology of tin plating and pressing wheel, applied in hot dip plating process, coating, metal material coating process, etc., can solve the problems of difficult to control coating thickness, uneven coating thickness, and low product yield, etc. Easy operation, high production efficiency, and the effect of reducing the incidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

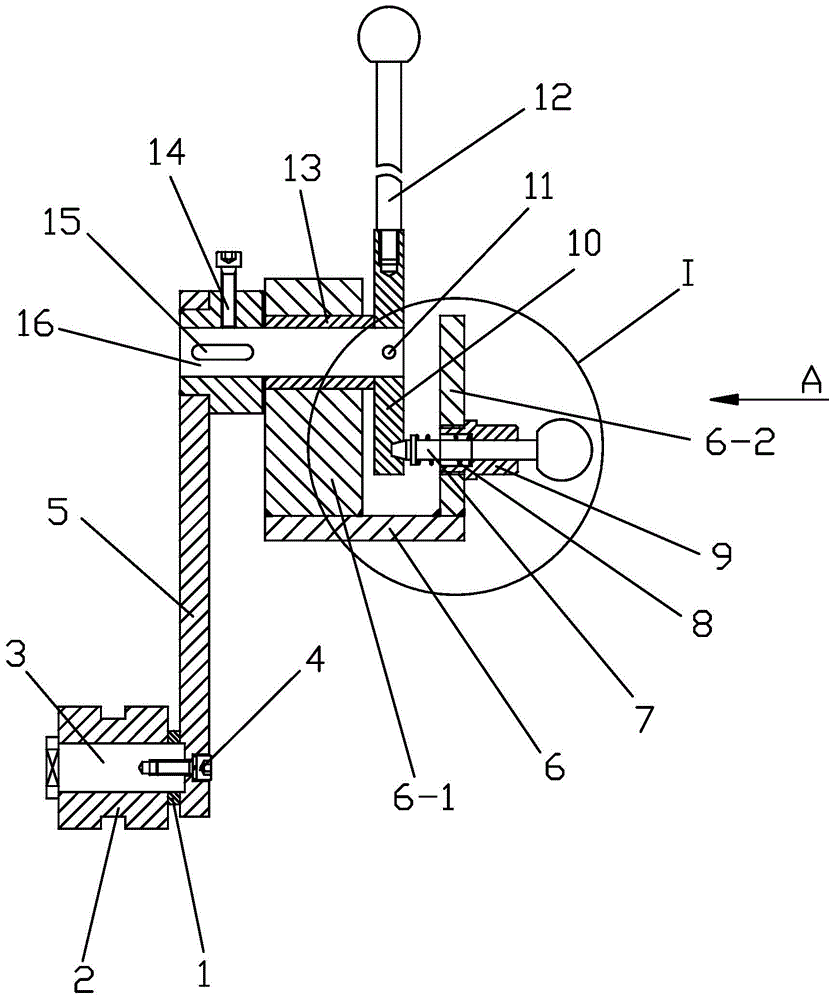

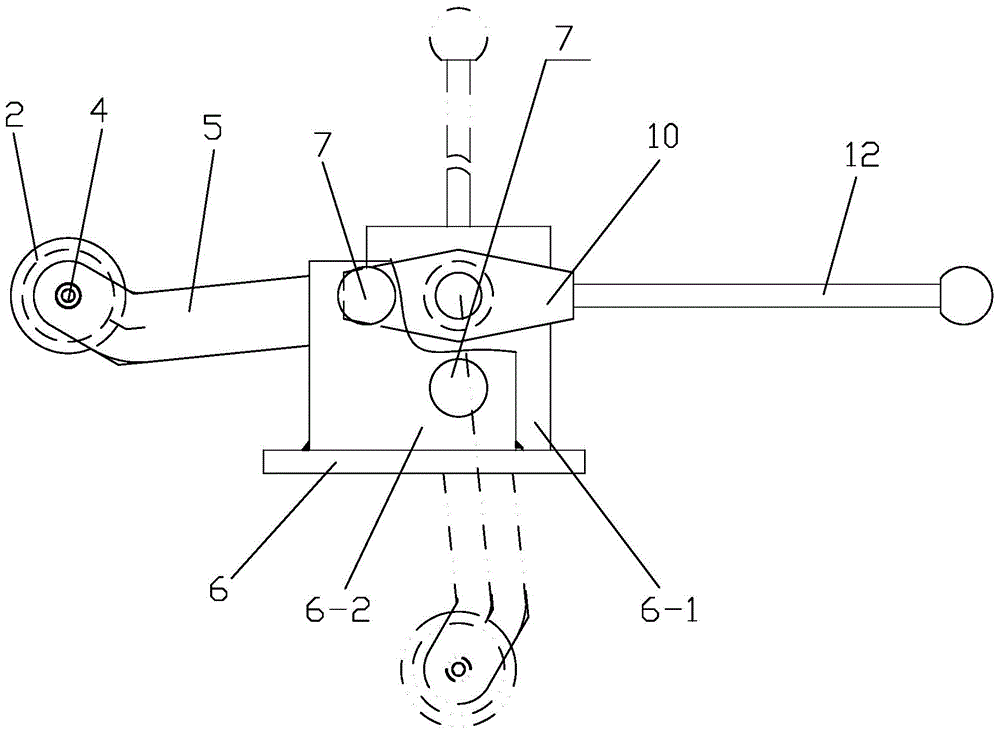

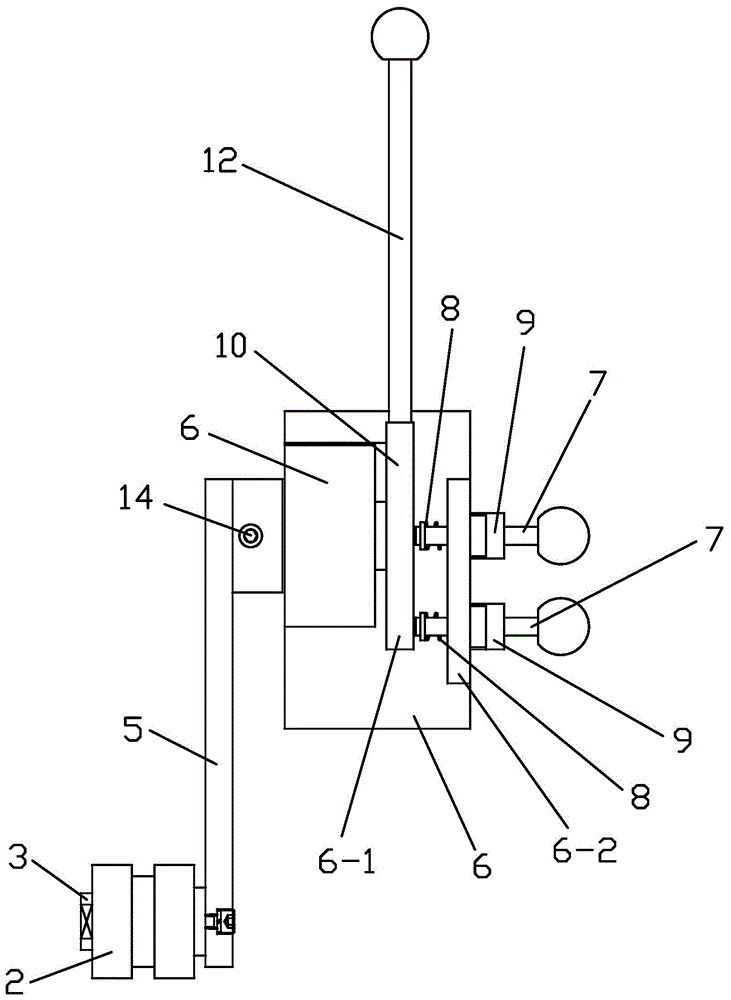

[0027] Such as Figure 1 to Figure 4 As shown, the present invention includes a base 6, a second shaft 16, a handle 12 and a swing arm 5, the base 6 is fixed with a first mounting plate 6-1 and a second mounting plate 6-2, and the first mounting plate 6-1 is located on the left side of the second mounting plate 6-2 and has a distance from the second mounting plate 6-2, and the first mounting plate 6-1 and the second mounting plate 6-2 are provided with plate 10, the plate 10 is installed on the right end of the second shaft 16 through the taper pin 11, the lower end of the handle 12 is fixedly connected with the plate 10, and the second mounting plate 6-2 is provided with a mounting plate for positioning the plate 10 Positioning mechanism, the left end of the second shaft 16 passes through the first mounting plate 6-1 and the upper end of the swing arm 5 in turn, a copper sleeve 13 is arranged between the second shaft 16 and the first mounting plate 6-1, The copper sleeve 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com