Buffer self-closing device for telescopic slide rail

A self-closing device and sliding rail technology, applied in furniture parts, home appliances, drawers, etc., can solve the problems of insufficient force, the drawer cannot be closed normally, and the sliding part is tripped, so as to increase the locking force and prevent abnormal The effect of tripping and improving reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

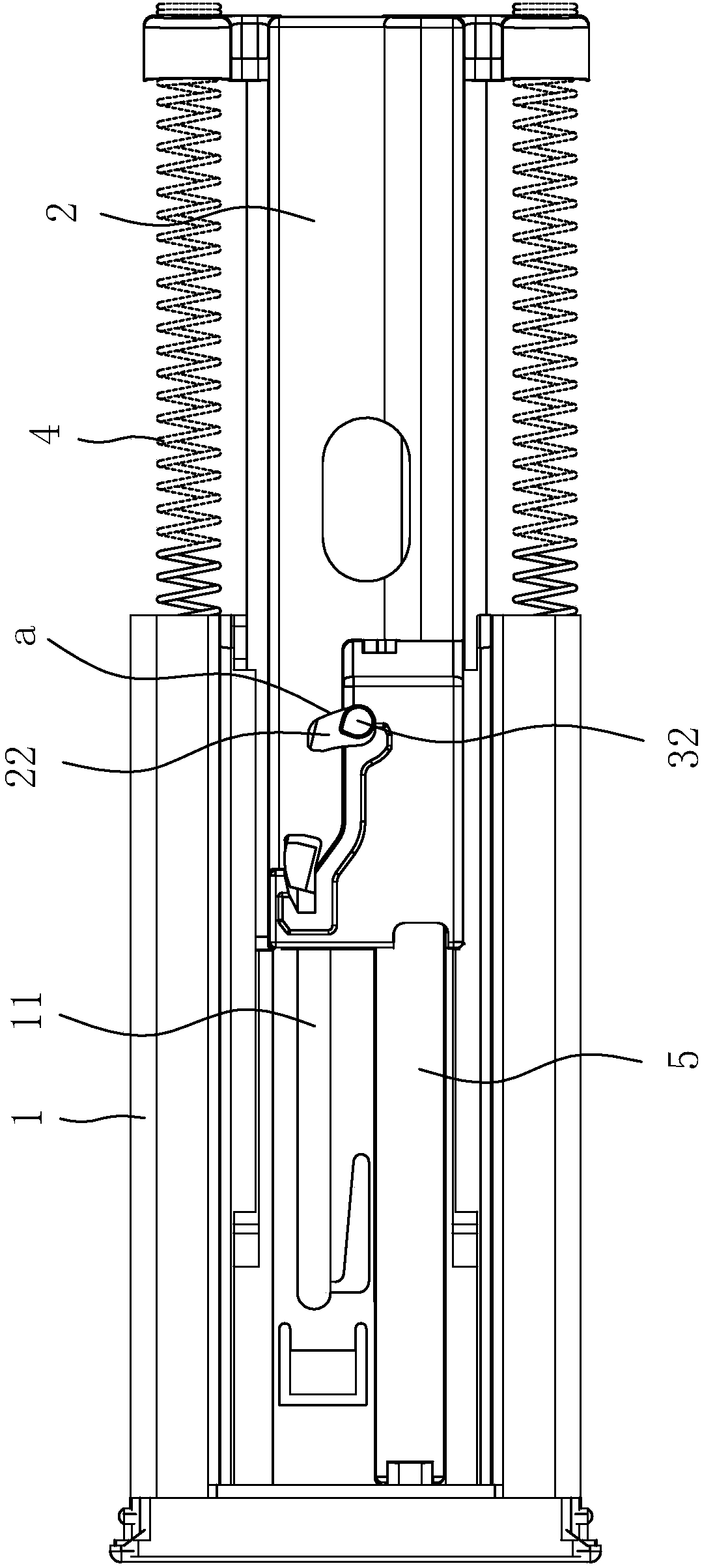

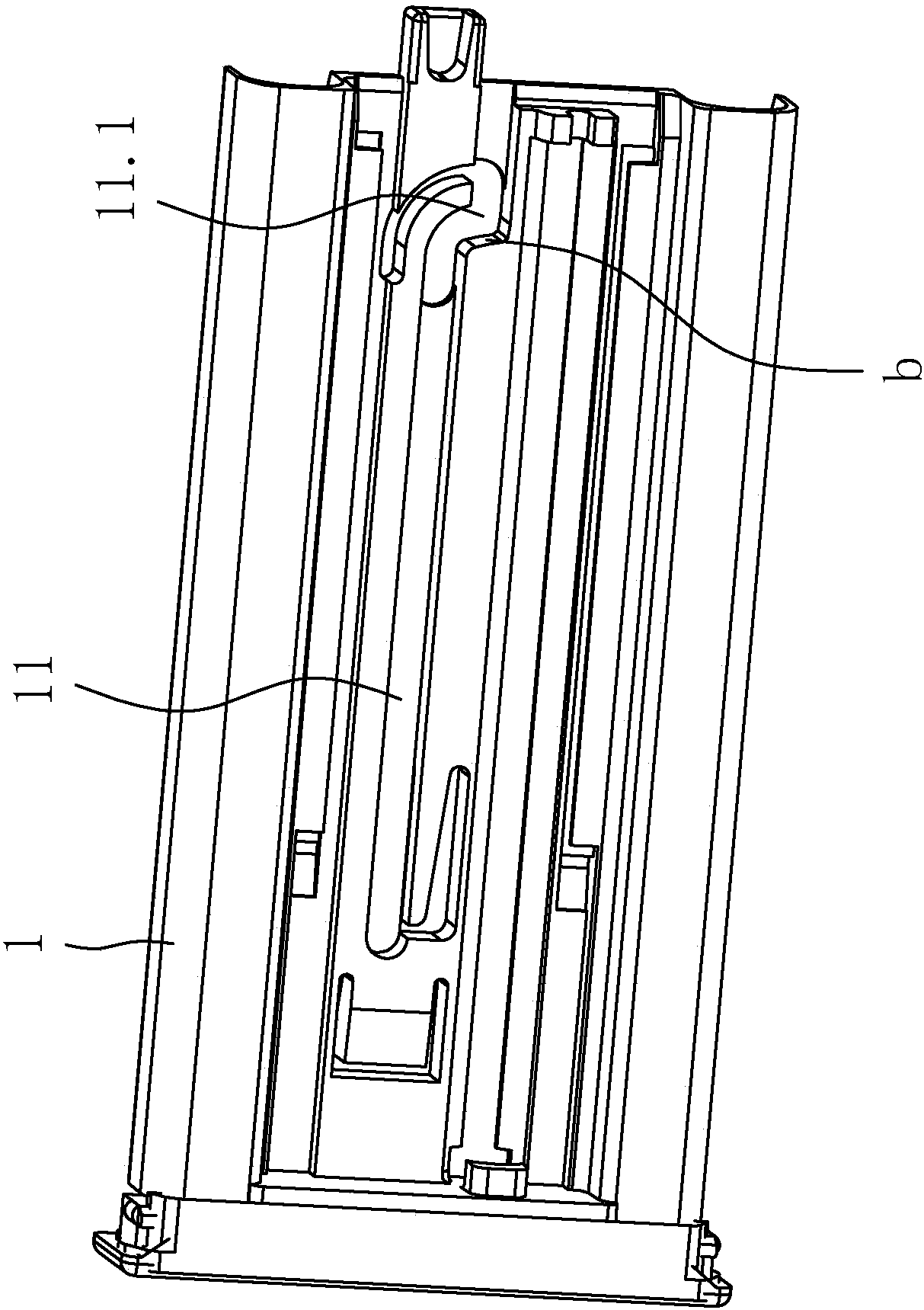

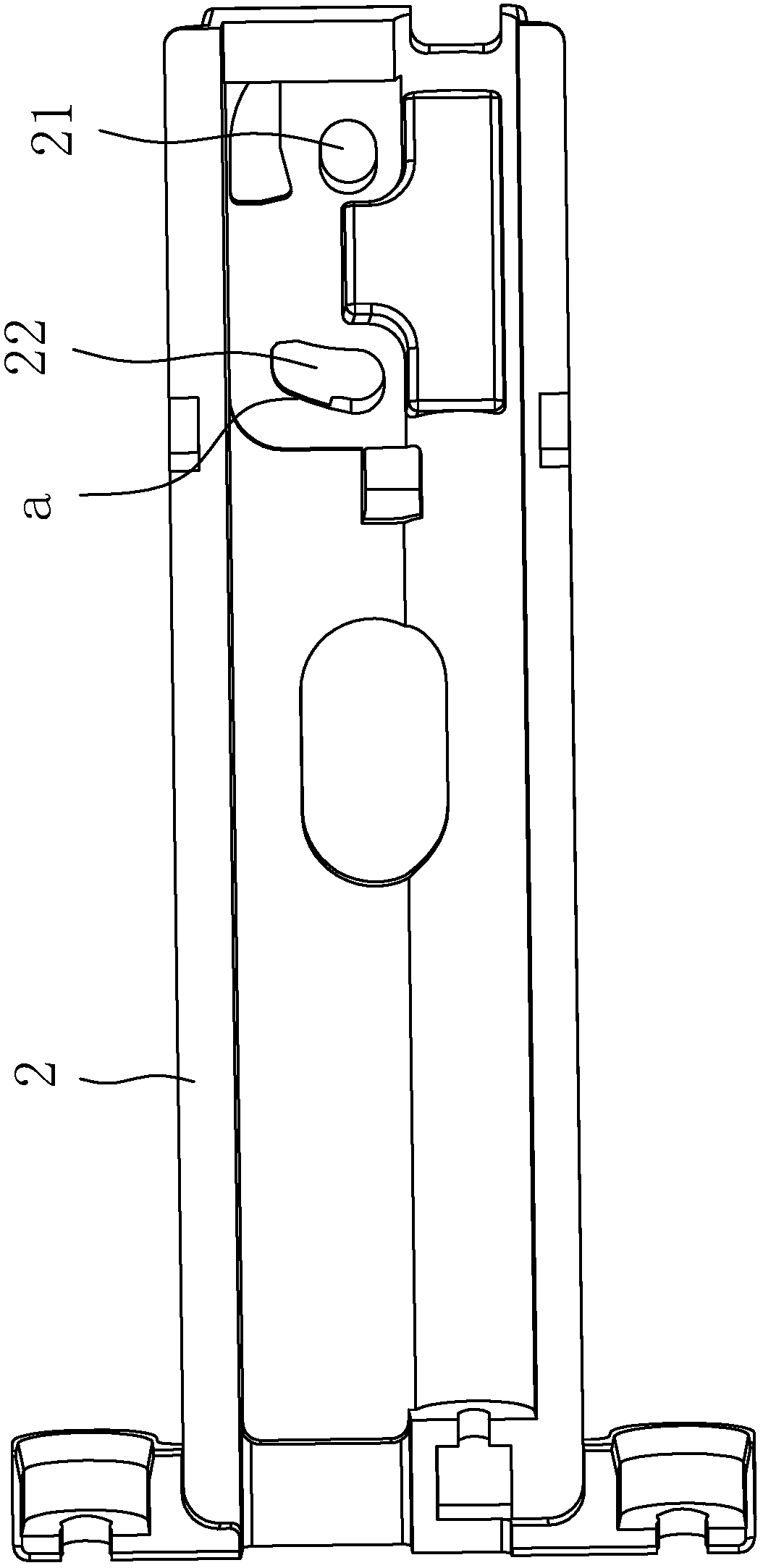

[0013] Such as Figure 1-4 As shown, a buffer self-closing device for a telescopic slide rail includes a base 1, a sliding seat 2 slidingly matched with the base 1, a sliding buckle 3, and a spring 4 and a damper connected between the base 1 and the sliding seat 2 5. There is a chute 11 on the base 1, and the slide-out end of the chute 11 corresponding to the sliding seat 2 is bent into a corner 11.1. The sliding buckle 3 is connected to the sliding seat 2 through the rotating shaft 31 and is slidably matched with the chute 11. The two ends of the buckle 3 in the sliding direction respectively form protrusions 32 and 33 that protrude from the sliding seat 2 and swing around the rotating shaft 31. Among them, the protrusions 32 correspond to the sliding direction of the sliding seat 2, and the protrusions 32 correspond to the sliding direction of the sliding seat 2. Protruding column 33 . In the present invention, the shaft hole 21 for installing the rotating shaft 31 of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com