Molten salt heat storage single-tank internal arrangement heat exchange off-peak electricity steam boiler and heat exchange method

A technology of steam boiler and molten salt, applied in the field of electric steam boiler, can solve problems such as high cost, achieve the effect of saving material cost and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

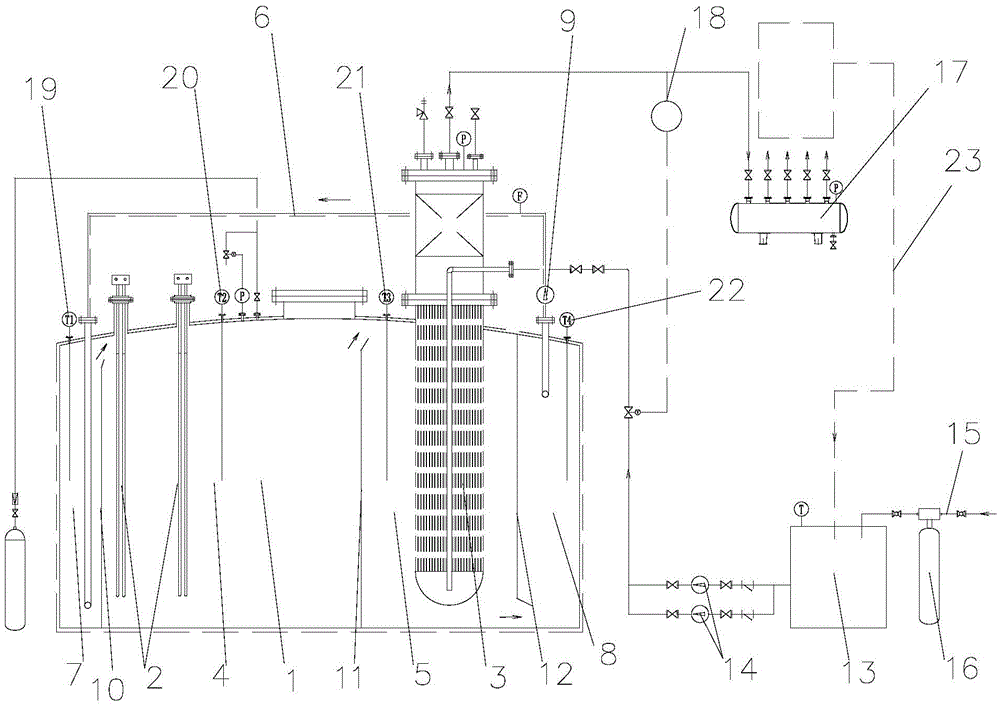

[0029] Such as figure 1 As shown, this embodiment provides a single-tank built-in heat exchange valley electric steam boiler for molten salt heat storage, including a molten salt tank 1, an electric heater 2 and a steam generator 3, and the electric heater 2 is arranged on the The electric heating zone 4 inside the molten salt tank 1, the steam generator 3 is arranged in the heat exchange zone 5 inside the molten salt tank 1, and the molten salt in the molten salt tank 1 passes through the electric heating zone 4 The electric heater 2 flows to the heat exchange area 5 after being heated to realize heat release, and the cooled molten salt circulates to the electric heating area 4 through the molten salt transmission pipeline 6 .

[0030] The molten salt tank 1 also includes a low-temperature zone 7 and a low-temperature suction zone 8. The low-temperature zone 7, the electric heating zone 4, the heat exchange zone 5 and the low-temperature suction zone 8 are sequentially divide...

Embodiment 2

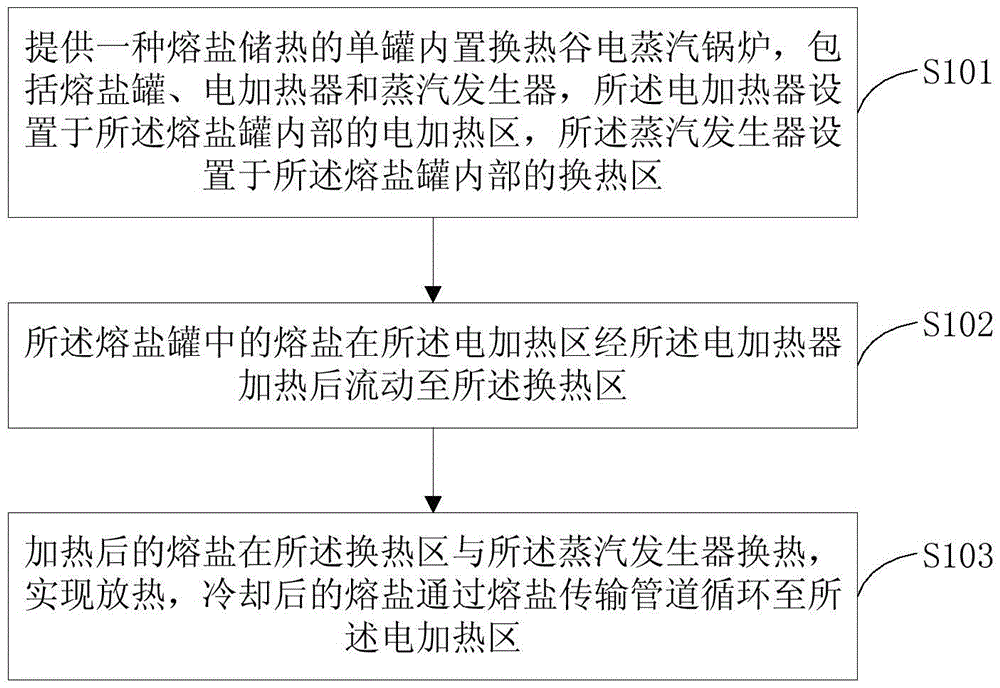

[0044] Such as figure 2 As shown, this embodiment provides a method for molten salt heat storage and heat exchange, including:

[0045] S101, providing a single-tank built-in heat exchange valley electric steam boiler for molten salt heat storage, including a molten salt tank, an electric heater and a steam generator, and the electric heater is arranged in an electric heating area inside the molten salt tank , the steam generator is arranged in the heat exchange area inside the molten salt tank.

[0046] S102, the molten salt in the molten salt tank flows to the heat exchange area after being heated by the electric heater in the electric heating area.

[0047] S103, the heated molten salt exchanges heat with the steam generator in the heat exchange area to realize heat release, and the cooled molten salt circulates to the electric heating area through the molten salt transmission pipeline.

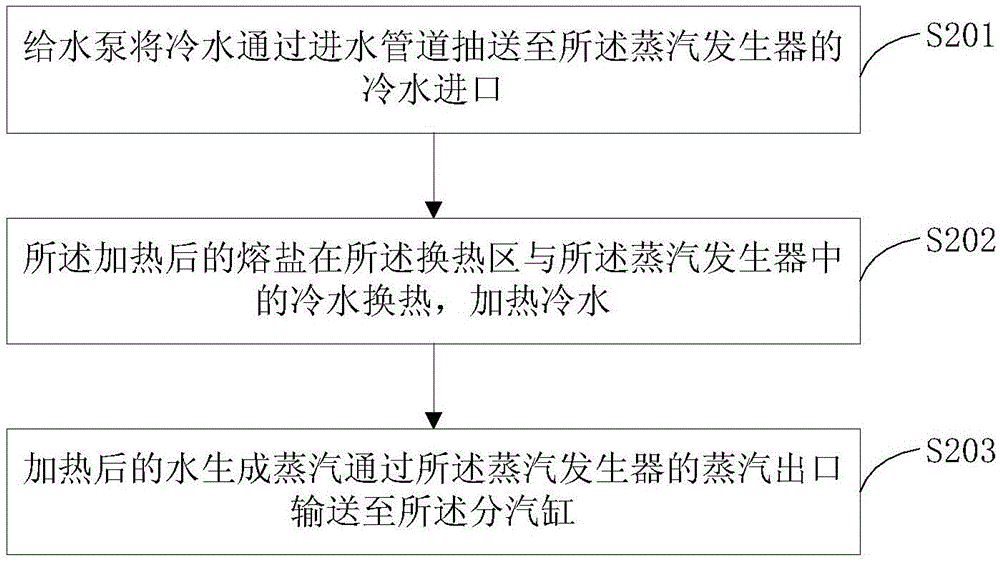

[0048] Among them, such as image 3 As shown, the production of steam by heat stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com