Hydraulic support loading and unloading device in roadway

A technology of hydraulic support and loading and unloading device, which is applied to mine roof support, mining equipment, earthwork drilling and other directions, can solve the problem of increasing manpower and material resources, affecting the installation and retraction progress of the working face, and cannot meet the production and use of modern mine equipment. capacity and other issues to achieve the effect of reducing human and material investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] 2. How to use the hydraulic support loading and unloading platform

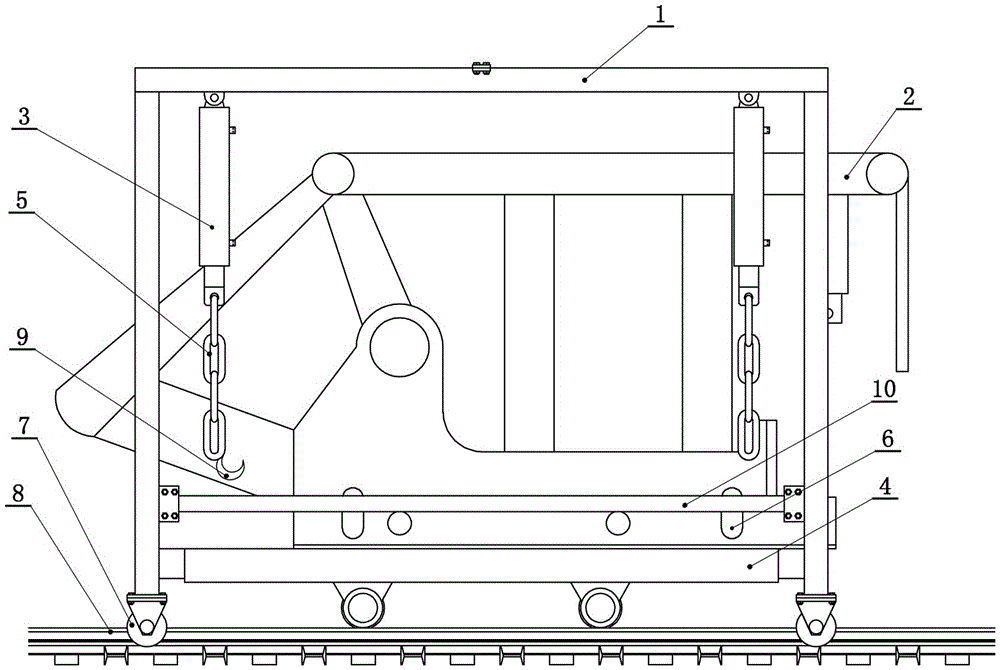

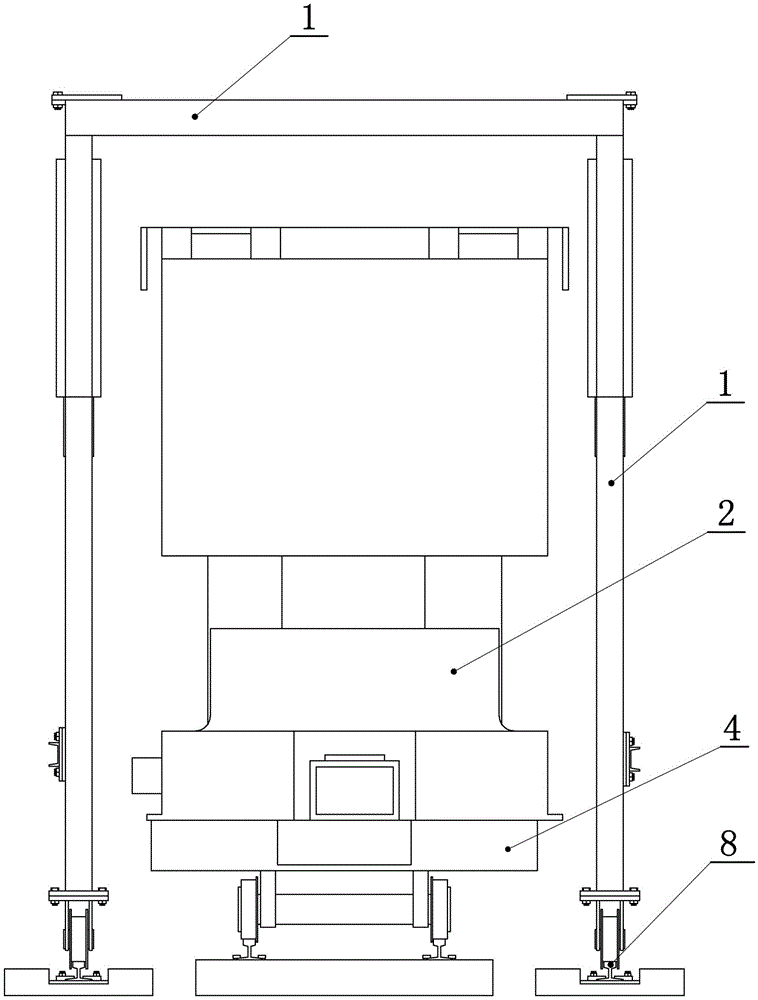

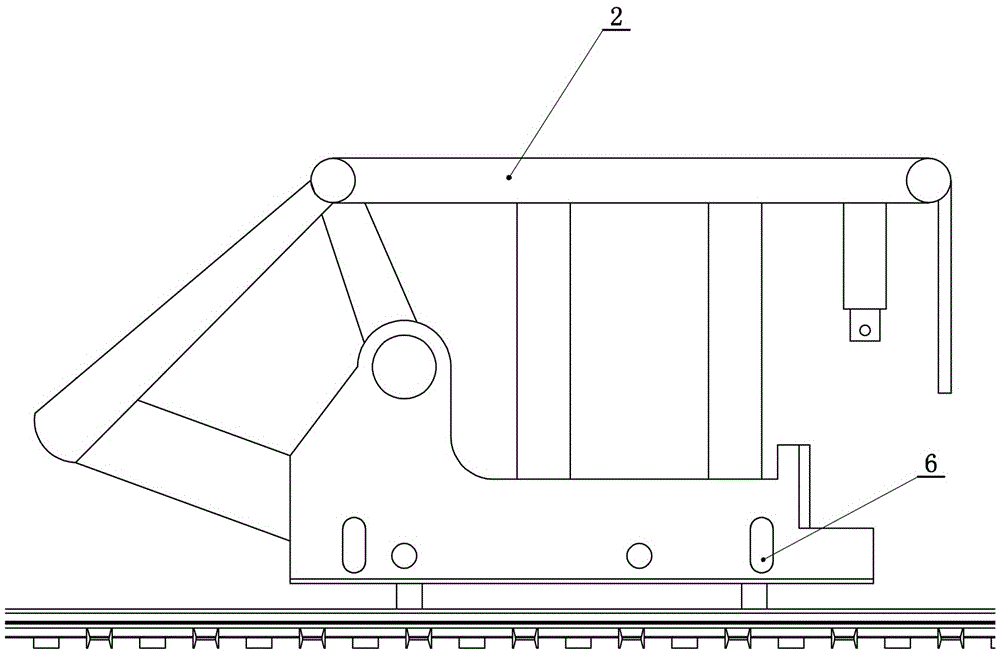

[0020] The hydraulic support loading and unloading platform has a gantry frame structure as a whole. There are two telescopic jacks on the upper beams on both sides. Each jack is locked by a one-way valve and controlled by a control valve. The way of movement is two-way alternate way forward.

[0021] working principle:

[0022] 1. The two tracks of the hydraulic support loading and unloading device are auxiliary set on both sides of the roadway track, and after the second section is connected, the hydraulic support loading and unloading device is fixed on the running rail, and the hydraulic support to be unloaded is pushed into the hydraulic pressure along the roadway track. In the bracket loading and unloading device, operate the four jacks on both sides of the loading and unloading device to recover, lift the hydraulic support, and under the action of the one-way valve, the hydraulic support stays ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com