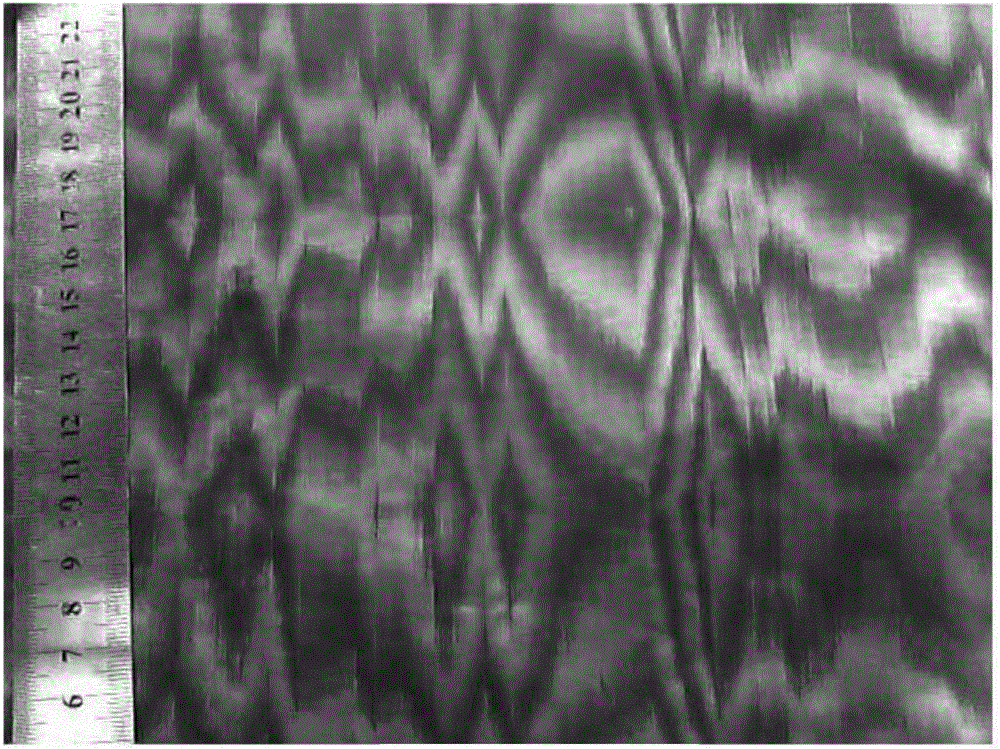

Dreamlike large board pattern fabric

A kind of pattern and large-scale technology, applied in the field of clothing and home textile fabrics, can solve the problems of large cycle, unrealizable, complex texture structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

[0016] The present invention relates to a fabric with a dreamy large wooden board pattern, which includes warp yarns and weft yarns of different colors; the arrangement sequence of the warp yarns and weft yarns is based on the natural annual ring pattern patterns, and is formed by respectively adopting the forward and backward stacking method, The advance and retreat stacking method is formed by combining the advance and retreat method, the stacking method and the stacking method on the basis of the five-in-one method;

[0017] The threading sequence of the five-in-one method adopts the following cycle: 1.2.3.4.5, 2.3.4.5.6, 3.4.5.6.7, 4.5.6.7.8, 5.6.7.8.9, 6.7.8.9.10 , 7.8.9.10.1, 8.9.10.1.2, 9.10.1.2.3, 10.1.2.3.4.

[0018] The threading sequence of the advance and retreat method means that the numbers can a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com