Font parallel fine-tuning system

A font and font template technology, applied in the field of font parallel fine-tuning system, can solve the troublesome and time-consuming adjustment of the font box plane, affect production efficiency, and inconvenient problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

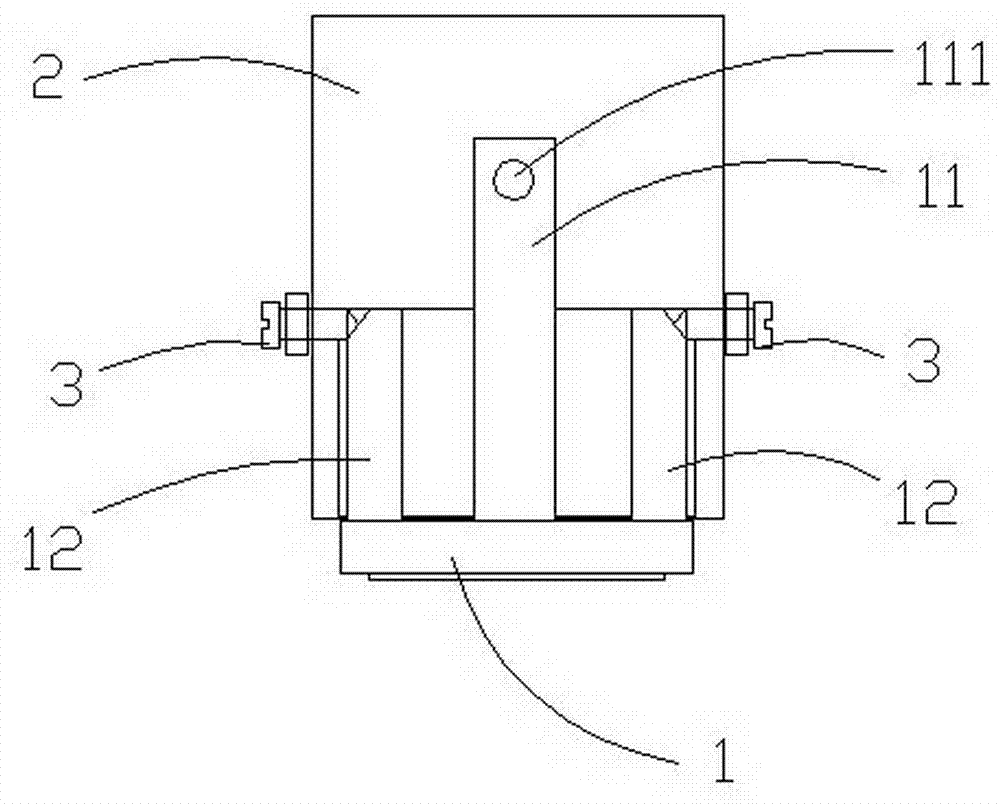

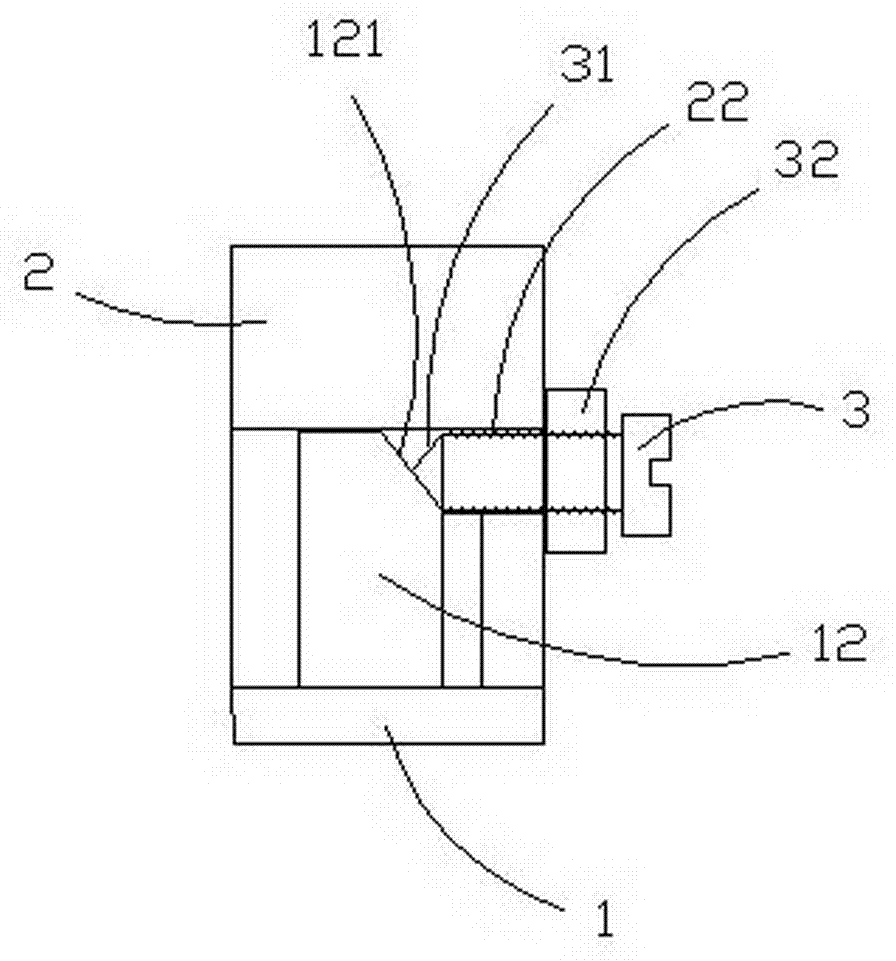

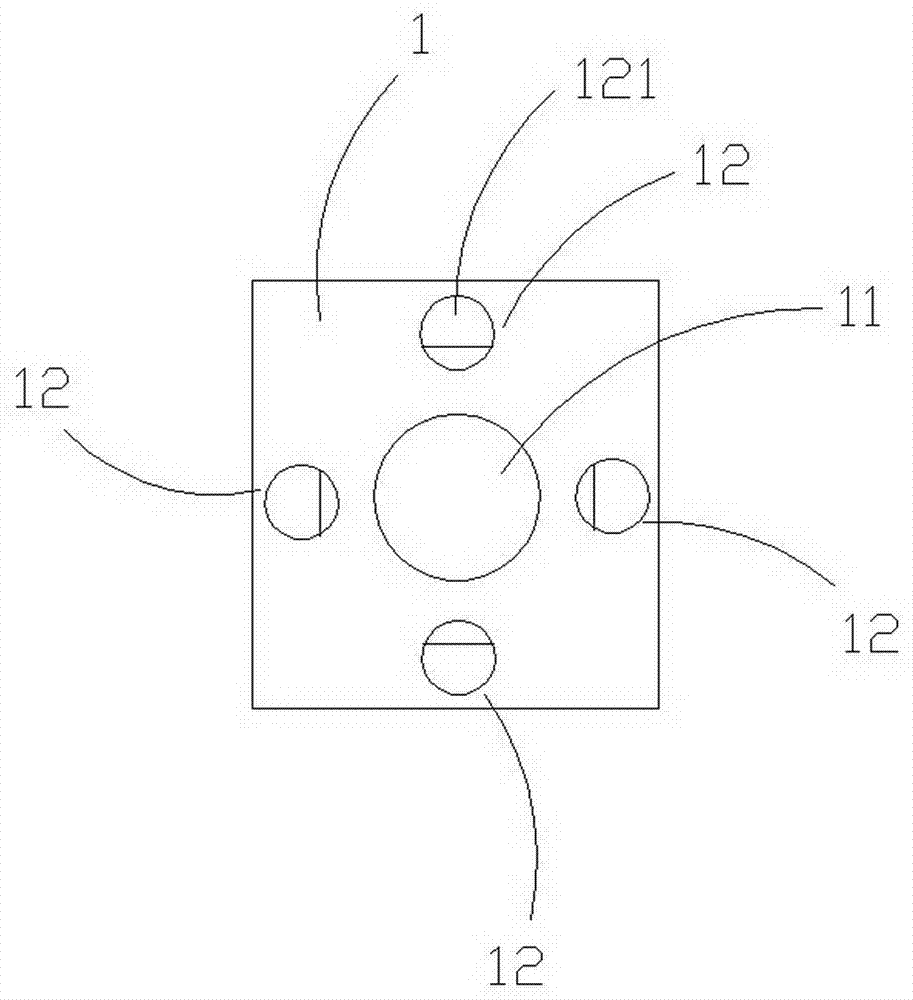

[0014] like figure 1 , 2 , shown in 3, a kind of font parallel fine-tuning system, comprises font template 1 and the font control 2 that installs font template, the font backside of described font template 1 is provided with the mold handle 11 that is vertical with plate surface, the top of mold handle 11 Positioned screw holes 111 are provided, and four adjustment columns 12 with the same height and parallel to the axis of the mold handle 11 are evenly arranged around the mold handle 11. The outside of the top of the adjustment column 12 is a chamfered slope 121. Installed in the shaft hole of the font control 2 and fixed by bolts, the font control 2 is horizontally connected with an adjusting screw 3 that is threaded. The slopes 121 of the two adjustment columns 12 fit together accordingly, and the angle of the slope 31 of the adjustment screw 3 is the same as the angle of the slope 121 of the adjustment column 12 . Rotate the adjusting screw 3 to make the adjusting column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com