Car Seat Cushion Press Machine

A technology for car seats and cushions, applied in the field of auto parts, can solve the problems of wasting manpower and poor cushion effect, and achieve the effects of reducing labor, improving product quality, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

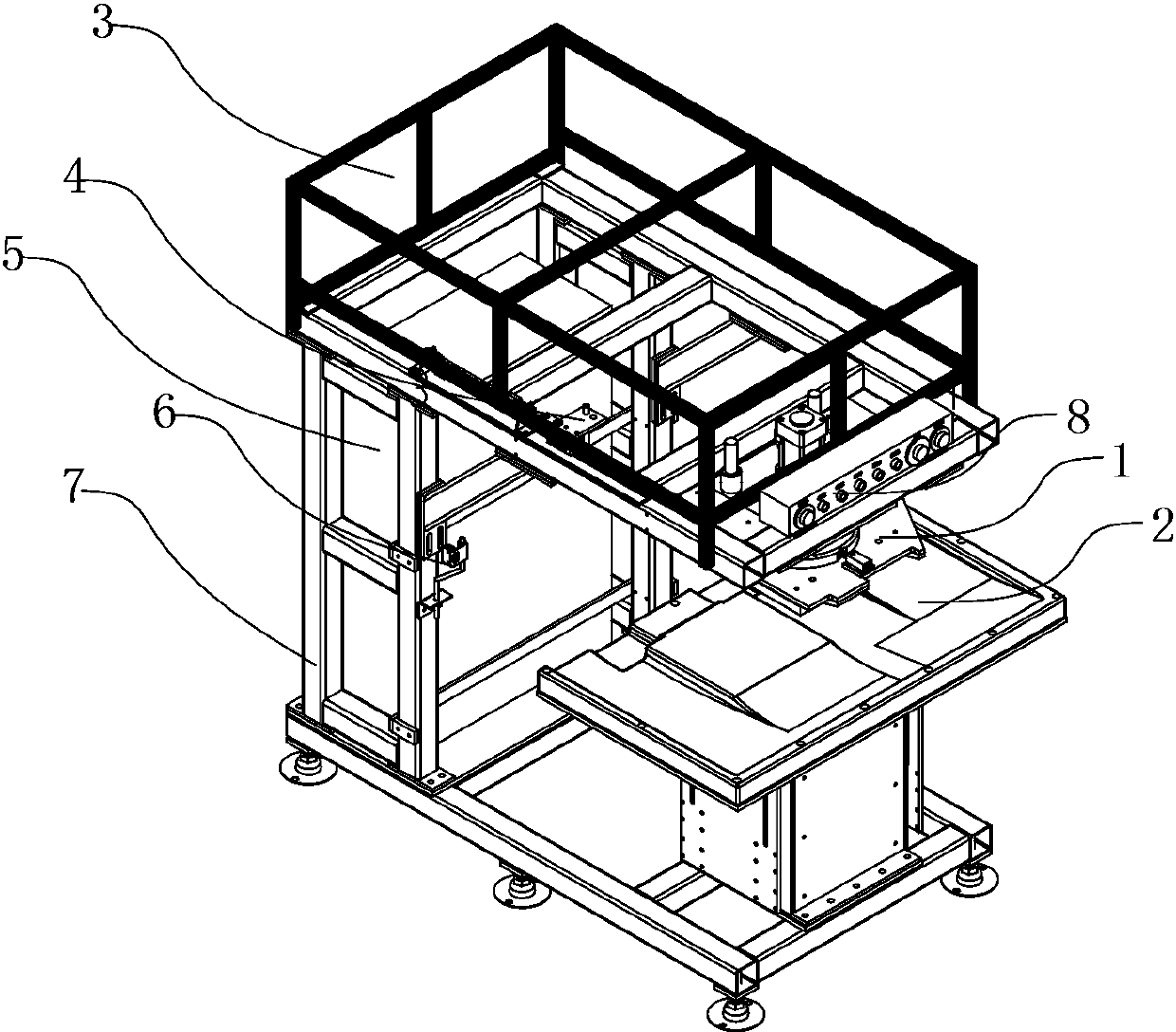

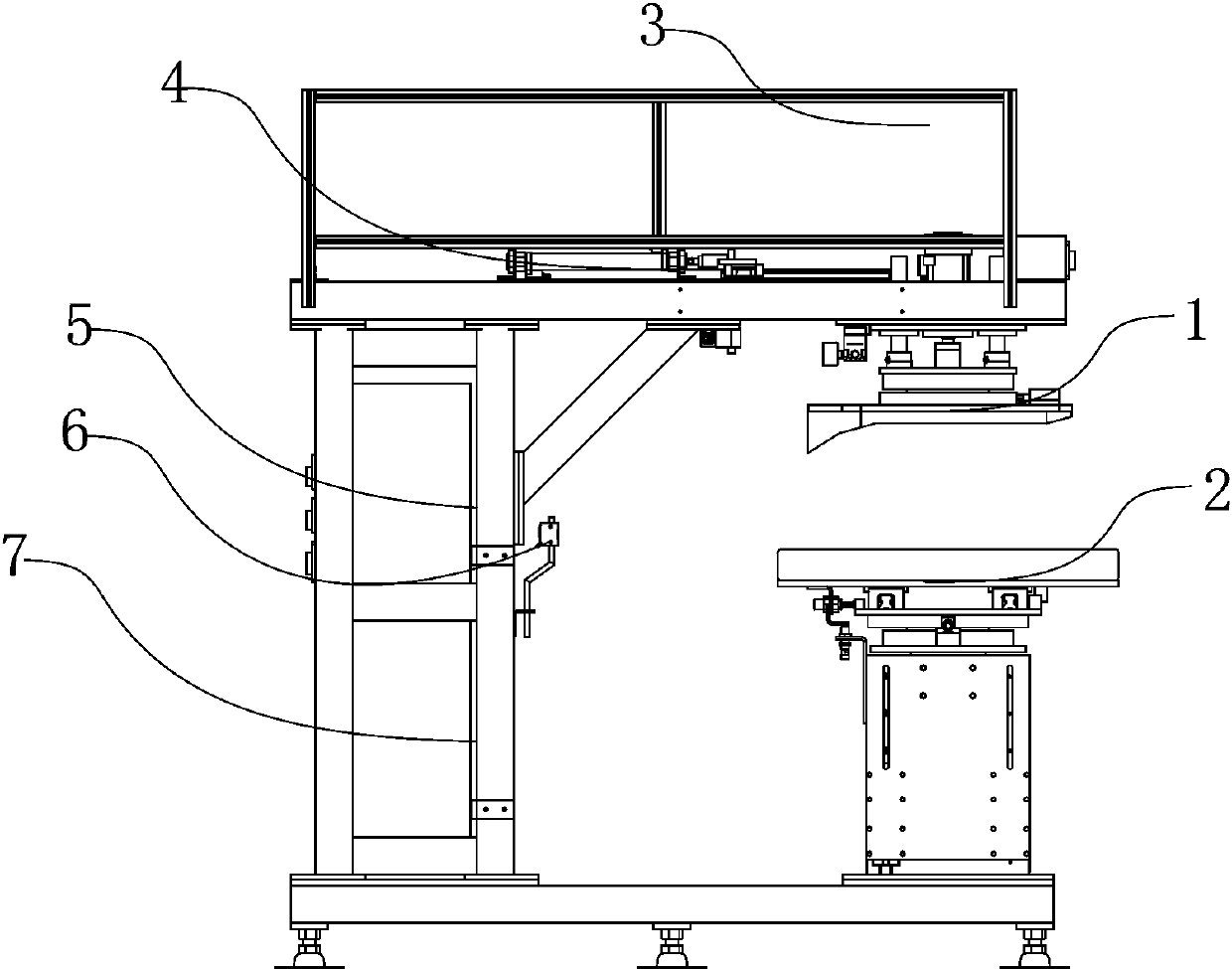

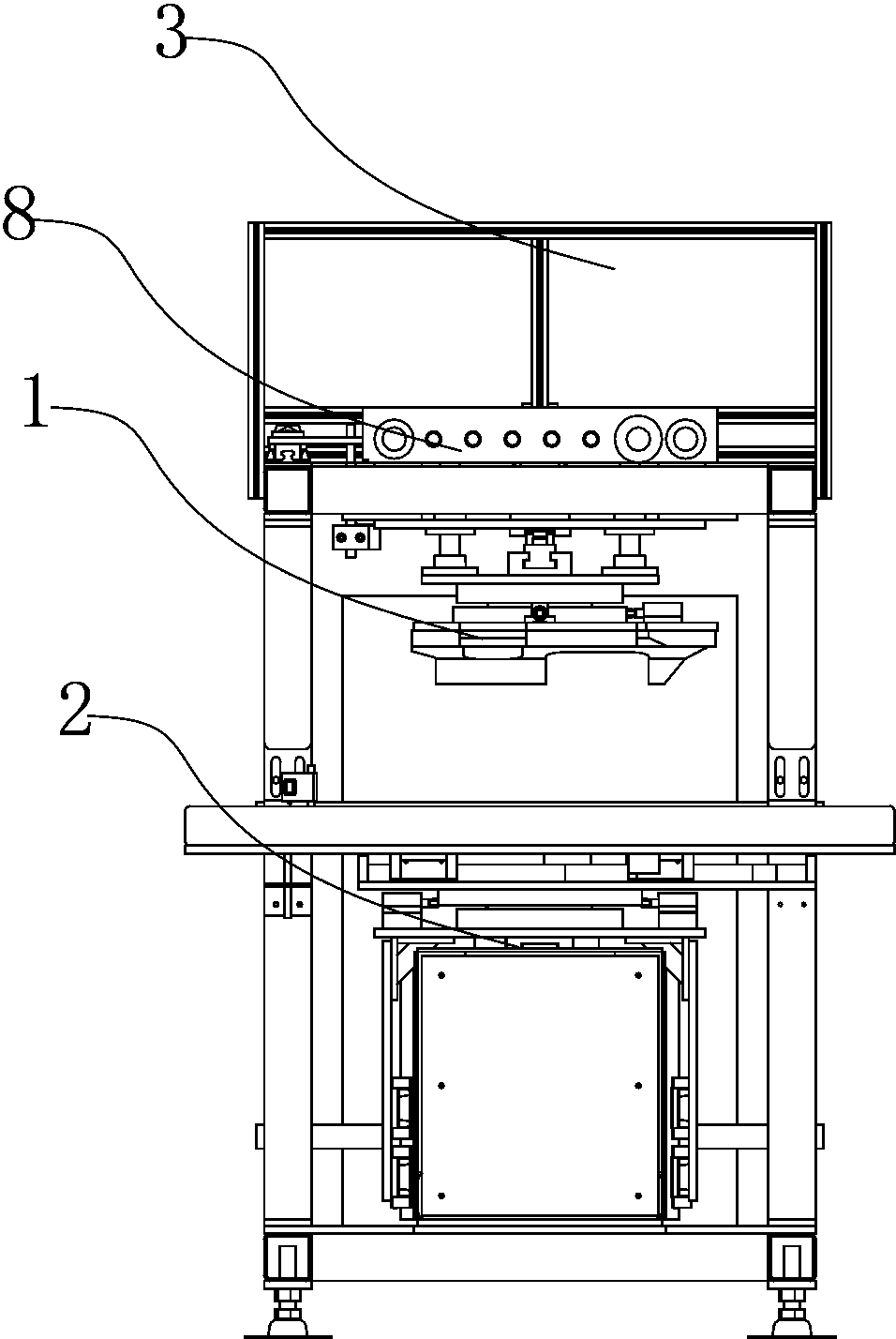

[0021] The car seat rear cushion press machine includes an upper pushing force assembly 2, a lower pressing power assembly 1 and a moving vision assembly 4. The upper pushing assembly 2 is provided with a profiling lower die 21, and the lower pressing power assembly 1 A profiled upper die 11 aligned with the profiled lower die 21 is arranged on the top, and the described profiled upper die 11 and the described profiled lower die 21 can rotate synchronously, and the described profiled upper die 11 and the described The profiling lower die 21 can be raised and lowered, and the upper driving force assembly 2 includes a first cylinder, and guide rails 22 are arranged on both sides of the first cylinder, and a profiling lower die 21 is arranged on the top of the guide rails 22. A first cross roller bearing is arranged in the first mounting seat belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com