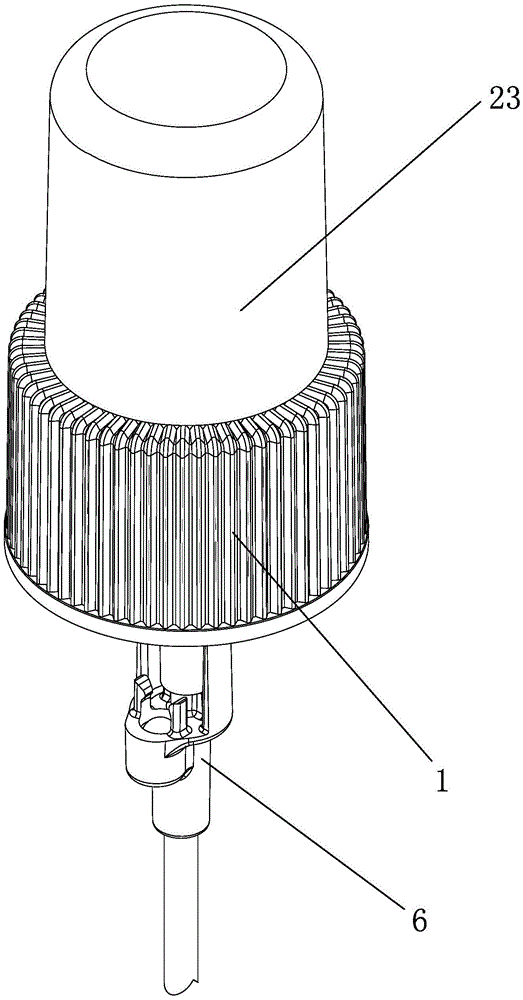

Universal lotion pump with outside mounted spring

A technology of lotion pump and pump body, which is applied in the field of universal lotion pump with external spring, which can solve the problems of affecting the use effect, unhygienic, complicated structure, etc., and achieve the effect of simple structure, ingenious design and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

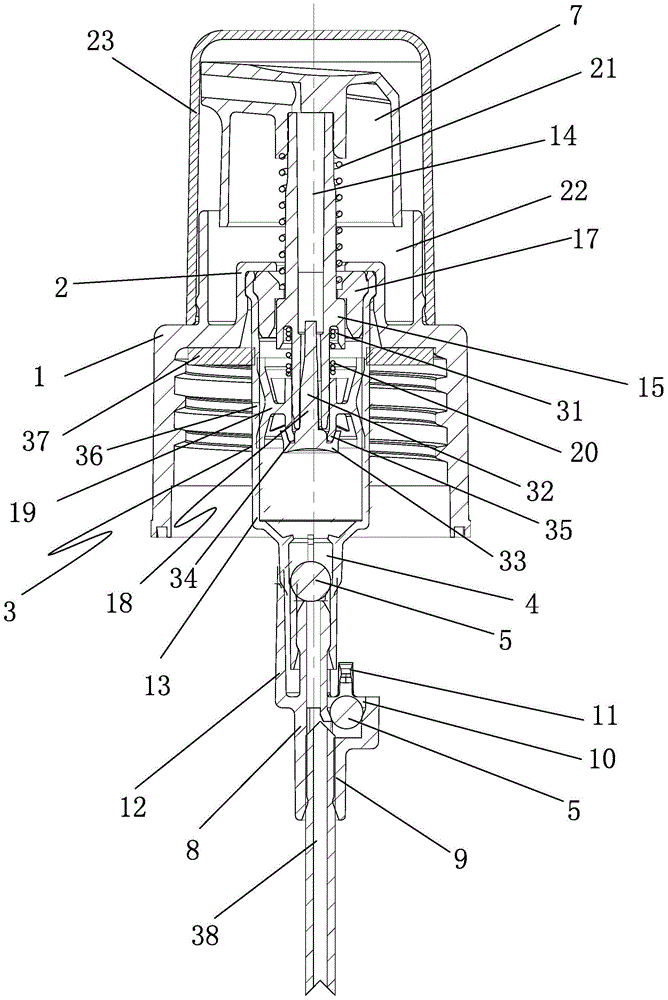

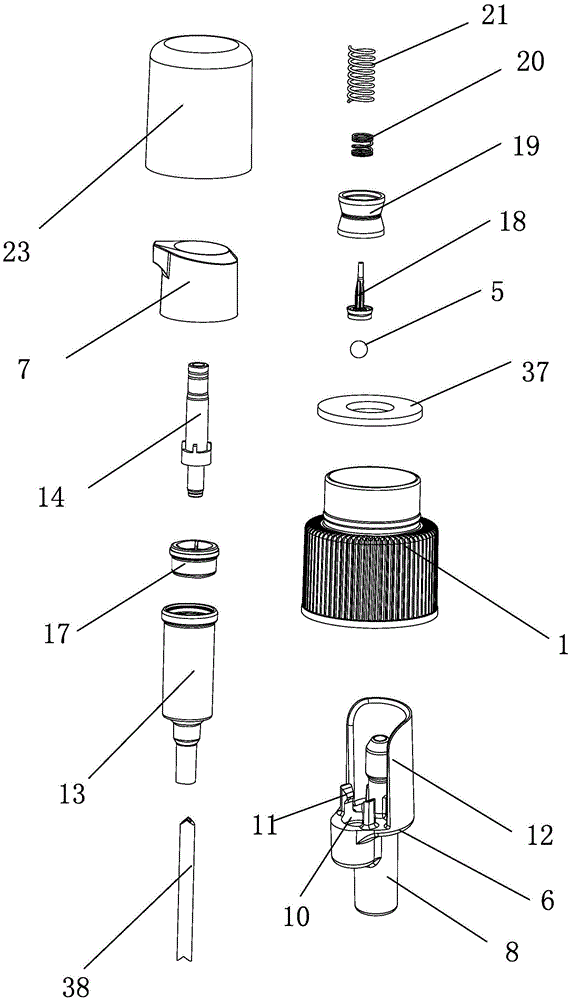

[0033] The first embodiment of the connection mechanism 24 of the present invention includes an accommodating groove 25 arranged in the bottle lock cap 1, a spring 26 is arranged in the accommodating groove 25, and a spring 26 is connected to the upper end of the spring 26. An elastic cord 27 , one end of the elastic cord 27 is connected to the outer cover 23 .

[0034] In the second embodiment of the connection mechanism 24 of the present invention, the connection mechanism 24 includes a slide groove 28 opened on the inner wall of the outer cover 23, and a connection bar 29 is provided on the outer convex connection ring 22. A limiting slider 30 is arranged on the end of the bar 29 , and the limiting slider 30 is movably arranged in the slide groove 28 .

[0035] In the present invention, a positioning groove 31 is provided on the lower end surface of the positioning ring platform 15 , and the upper end of the secondary spring 20 is disposed in the positioning groove 31 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com