High-voltage cable detection robot equipped with electric field intensity detector

An electric field strength, high-voltage cable technology, applied in electrostatic field measurement, mechanical equipment, antenna supports/installation devices, etc., can solve problems such as inability to observe and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following describes the present invention in further detail with reference to the accompanying drawings and specific embodiments, without limiting the scope of implementation of the present invention.

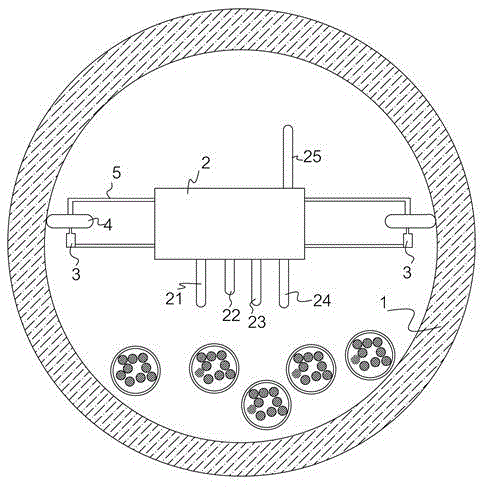

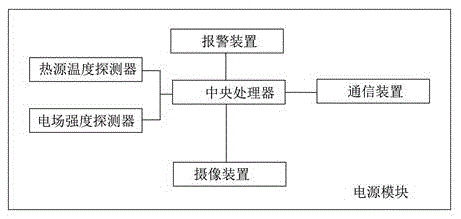

[0034] Such as Figure 1 to Figure 9 As shown, the high-voltage cable detection robot provided with electric field intensity detectors in this embodiment includes a robot main body 2. Both sides of the robot main body 2 are provided with L-shaped shaft arms 5, and the free shaft arms 5 The end shaft is connected with a roller 4 for making the robot body 2 move forward or backward in the cable duct 1, and the roller 4 abuts against the inner wall of the cable duct 1; it also includes a drive motor 3 for driving the roller 4 to rotate; the robot The main body 2 includes a control circuit, the control circuit includes a power module, and the power module is used to supply power to the drive motor 3 and the control circuit; the control circuit also includes a central proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com