Connection kits for magnetic contactor coils

A technology for connecting components and contactors, which is applied in the field of electricity, can solve the problems of rigid direct-connected conductors with many bends, difficult processing and assembly, and complex shapes, and achieves the effects of reducing processing costs, simple structure, and easy deformation correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

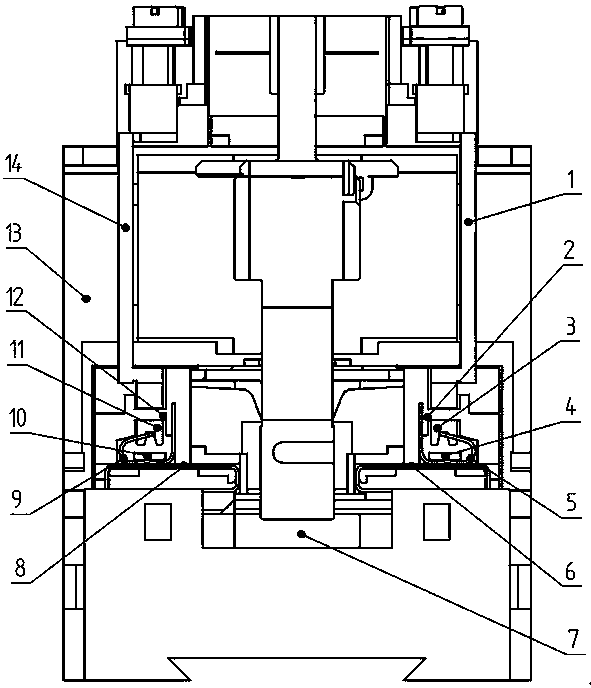

[0021] figure 1 Shown is an embodiment of the present invention: a connection assembly for an electromagnetic contactor; it includes a housing 12, and a left control signal input and output terminal 14 connected to an external power supply is installed symmetrically in the housing 12 It is connected with the control signal input and output terminal 1 on the right, the lead-out terminal 8 of the coil inlet and outlet on the left side, the lead-out terminal 6 of the coil inlet and outlet on the right side, and two connecting parts, one coil 7. Part 9 and the right sheet-shaped folded elastic connector 5; see Figure 5 : Taking the left sheet-shaped folding elastic connecting piece 9 as an example, one end of the left sheet-shaped rolling elastic connecting piece 9 is provided with a vertical section 901, the other end is provided with a through hole 902, and the lower end of the vertical section 901 is provided with approximately 90 Degree arc bending 903, the rear section of 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com