A clamping and retrieving mechanism for ceramic products

A technology of reclaiming mechanism and ceramic products, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of poor automation and low efficiency, and achieve the effect of high automation, high efficiency and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

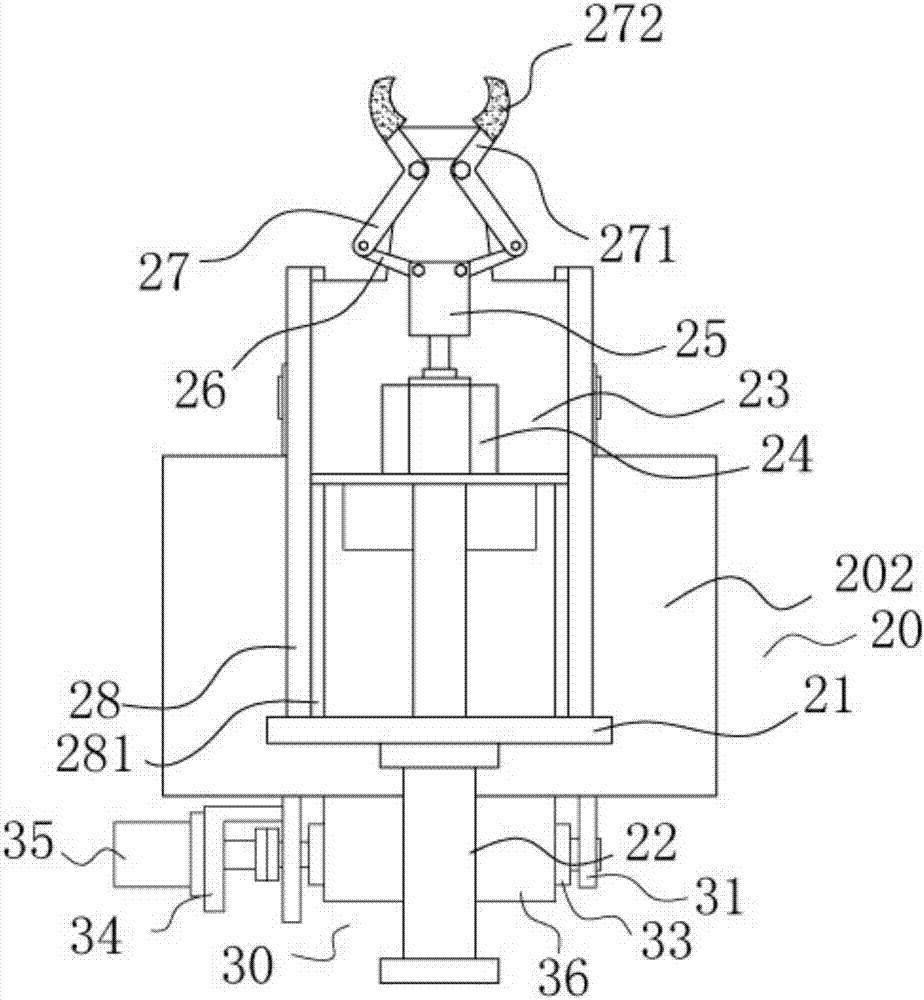

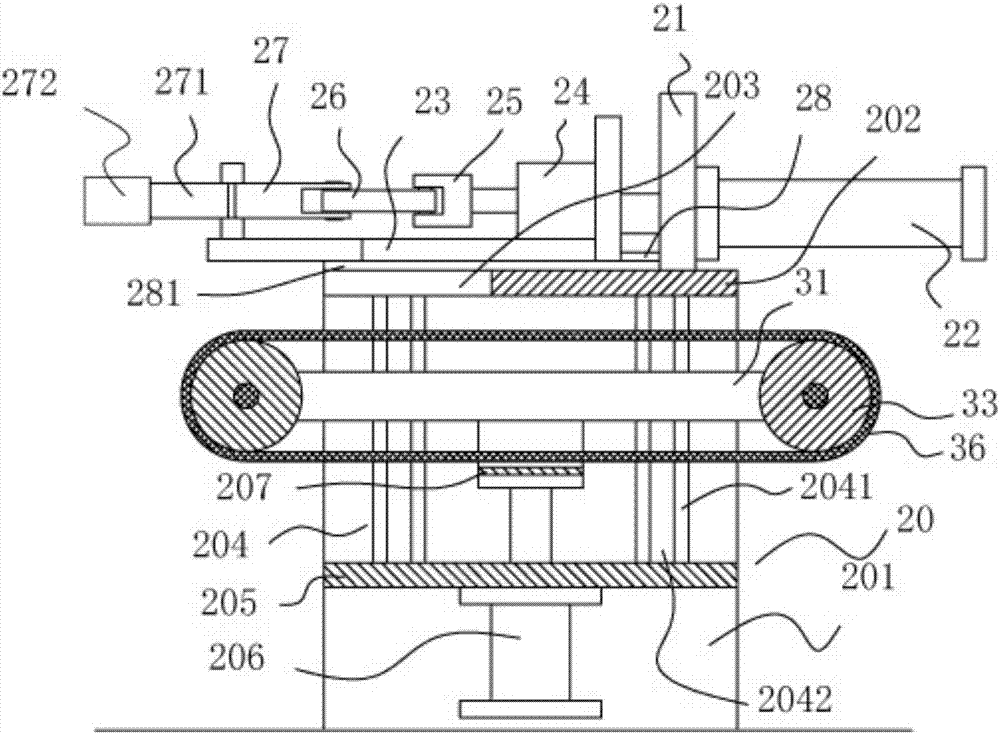

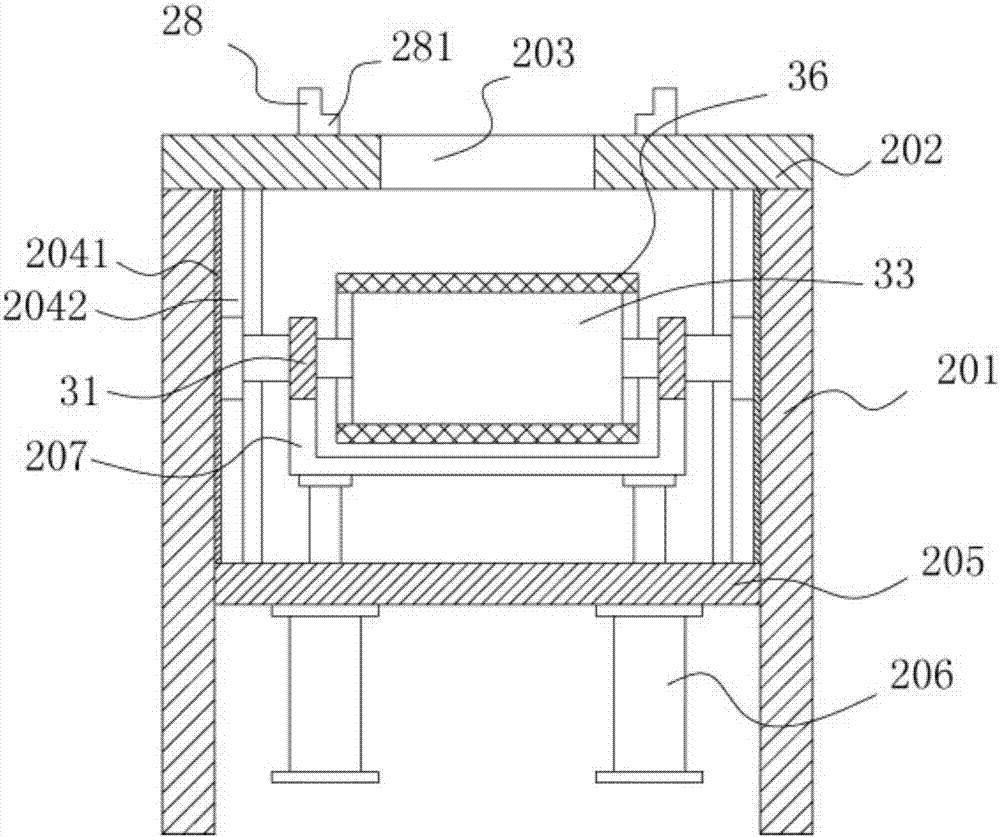

[0018] Example: see Figure 1 to Figure 3 As shown, a clamping and retrieving mechanism for ceramic products includes a clamping frame 20, a top plate 202 of the clamping frame 20 is fixed with a connecting plate 21, and a pushing cylinder 22 is fixed on the connecting plate 21, and the push rod of the pushing cylinder 22 Through the connecting plate 21 and fixed with a clamping plate 23, the middle part of the top plate 202 of the clamping frame 20 below the front part of the clamping plate 23 has a blanking channel 203, and the clamping plate 23 is fixed with a clamping cylinder 24, A connecting block 25 is fixed on the push rod of the clamping cylinder 24, the first rotating arm 26 is hinged on both sides of the front end of the connecting block 25, the front end of the first rotating arm 26 is hinged with a clamping arm 27, and the middle part of the clamping arm 27 is hinged. At the front end of the clamping plate 23, the front part of the clamping arm 27 is an outwardly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com