Stern roller design method of anchor handling towing supply vessel

A drum and stern technology, applied in the field of simplified three-purpose work stern drum structure design, can solve problems such as high strength requirements, lack of strength calculation basis of classification society, and structural nonlinearity, so as to reduce working capacity requirements and design time , The effect of controlling the design cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Design the tail drum of a three-purpose tugboat with a bollard drag force of 150 tons, the main parameters, the design load is 350 tons, and the length of the tail drum is 4000mm.

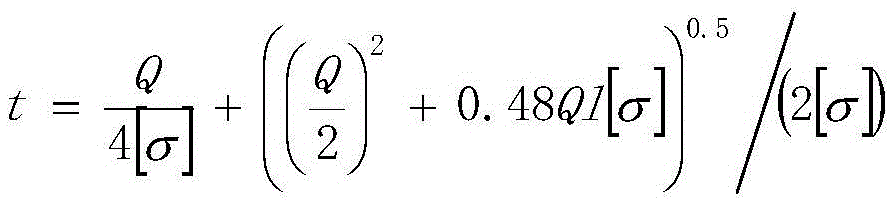

[0037] According to step 1 of the content of the invention, the formula for calculating the thickness of the cylinder shell is as follows,

[0038] t = Q 4 [ σ ] + ( ( Q 2 ) 2 + 0.48 Q 1 [ σ ] ) 0.5 / ( 2 [ σ ] ) ,

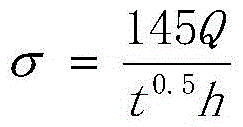

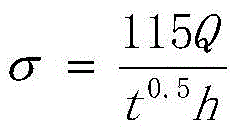

[0039] Accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com