Auxiliary device for drilling holes in outer edge of shaft

An auxiliary device and outer edge technology, applied in the direction of drilling dies for workpieces, etc., can solve problems such as difficulties, prone to problems, complex equipment structure, etc., to facilitate drilling, improve drilling efficiency, and facilitate market application and promotion. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the drawings and descriptions of the drawings.

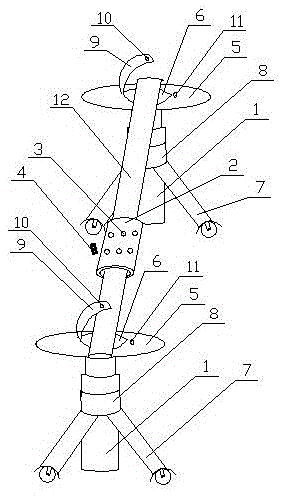

[0022] An auxiliary device for drilling on the outer edge of a shaft, comprising two hydraulic lifting devices 1 and a positioning sleeve 2, on the wall of the positioning sleeve 2 are provided a number of evenly arranged positioning threaded holes 3, and the positioning threaded holes 3 are internally screwed with a hollow Bolt 4, the inner wall of the hollow bolt 4 is a smooth inner wall, and the bracket plate 5 is connected with the top of the hydraulic lifting device 1 through bolts. On the hydraulic lifting device 1, a support frame 7 is set to keep the hydraulic lifting device stable. The support frame 1 is a tripod. A protective sleeve 8 is arranged on the top of the support frame 1. Bracket plate 5 is set, bracket 6 is set on bracket plate 5, bracket 6 is semicircular bracket, and the radius of bracket is 5-20mm, is provided with two rotatab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com