Grain conveying chain structure

A conveyor chain and grain technology, applied in the field of grain conveyor chain structure, can solve problems such as increasing the workload of equipment maintenance, reducing the amount of material conveyed, and cleaning complicated locks, so as to improve equipment operation efficiency, reduce its own weight, and reduce equipment maintenance workload effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

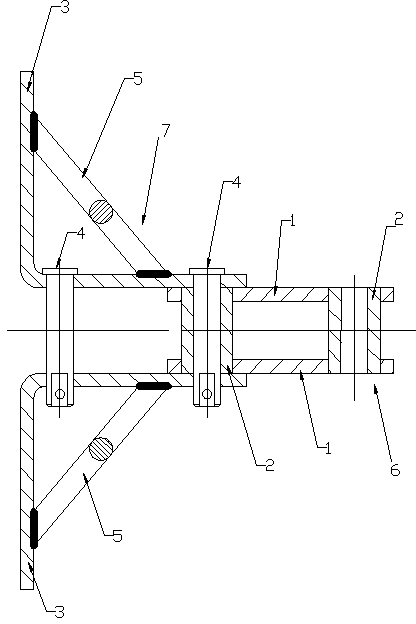

[0007] Such as figure 1 As shown, the present invention includes an inner chain link group 6 and an outer chain link group 7 which are alternately connected. The inner chain link group 9 includes two inner chain plates 1, and both ends of the two inner chain plates 1 are respectively provided with circular channels. The two inner chain plates 1 are provided with spacers 2 in the circular through holes at both ends of the interference fit.

[0008] The outer chain link group 7 includes two L-shaped outer chain plates 3; the two outer chain plates 3 of the outer chain link group 7 are symmetrically arranged on both sides of the inner chain link group, and the two outer chain plates of the outer chain link group 7 3 and the spacer 2 of the inner connection group are connected by a pin 4.

[0009] The inner sides of the two outer chain plates 3 of the outer chain link group 7 are respectively welded with reinforcing ribs 5, and the reinforcing ribs 5 are cylindrical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com